Based in the Netherlands, Tulp Jeans is a small operation run by Jesper Remmerswaal from a room at the back of his cozy apartment in the charming town of Delft. His passion for raw denim was instilled originally by his brother who taught him the secrets of the blue fabric and inspired him to push himself for more knowledge about jeans. As kids, they experimented with sandpapering the jeans, making holes on the fabric, repairing them, and even using bleach and paint, pretty much all that they could throw at the jeans to see what results and effects on the fabrics they could achieve.

It was this strong curiosity to know and learn that inspired Remmerswaal to study fashion with an emphasis on the design and construction of jeans. He was able to procure an old industrial sew machine to practice at home and was quickly became fascinated by the allure of denim and vintage sewing machines.

The motivation that pushed him to create Tulp Jeans was the drive make a pair of jeans with a typical Dutch flavour. And what better way to express the spirit of the Netherlands than with with their famous flower, the tulip? After brainstorming he decided to use the tulip as not only an image but also the name for his brand and the characteristic Dutch shape can be seen in the back pockets and in the fifth-pocket.

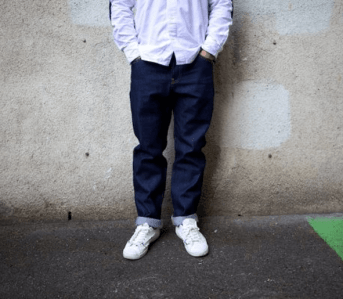

For his jeans he uses Japanese denim, sourced the Collect Mill, same mill as Momotaro’s denim, though he has also expanded recently into experimentation with American denim. His preference has been to use a minimum of 14oz denim, as in his experience it gives the finest works. For the inside, he has always have found it annoying that pockets bags broke within the first year of use so he came up with the idea to use a sturdy canvas to the point that now the linings of his jeans could almost outlast the denim itself! He also like to place the rivets in an old fashion way, not with a machine but manually hammering them in by hand.

Left, rivets worked by hand. Right, Remmerswaal on his work place

Remmerswaal has collected through the years a small but impressive collection of industrial sewing machines, giving the jeans the authentic touch that many denim heads strive for. He works with a Union Special 35800 feed off arm chainstich, one Reece101 keyhole machine, an Union Special 6900 Beltloop machine and an Union Special 39200 overlock.

Left, Reece machine Right, Union Special

Old Union Special

When asked about the future of Tulp Jeans, Remmerswaal says that he would like to have a production label that makes his brand available in various stores in the Netherlands and perhaps abroad. He also aspires to open an atelier where people can walk in and give their own preferences for a custom made jeans service, choosing denim, rivets, buttons, coloured yarns and more.

“The market for jeans is very big in the Netherlands. Wearing raw denim is increasingly beginning to grow. I think that for the raw denim lovers, smaller jeans brands who design until the final result with passion are more appreciated than big ones that are produced in an industrial way in factories” says Remmerswaal.

Left, denim bag made from 14.5 oz. Japanese selvedge, Right, Tulp yarns

Tulp Jeans are still a small brand trying to find their own place on the raw denim market, the competition is harsh and there have been more than a few casualties. That said, the passion reflected in the product is something that is not easily recreated and Remmerswaal captures this passion and puts it in every single yard, rivet, and stitch. You can find out a little more at Tulp Jeans as well as on Facebook.