Often when you’re reading about selvedge denim, people will wax on about the famous “vintage shuttle loom” but there isn’t much more information given about what makes these looms different from the more modern machines that are used to make the majority of the fabrics we see today.

Quick searches online will turn up plenty of information about different looms but a lot of it gets more technical than the average person would like to know and it can soon be overwhelming. In an attempt to simplify the information out there and to make sense of all this, we’re scratching the surface to differentiate how shuttle looms and projectile looms make denim.

Selvedge denim on a pair of Roy KS1002

Shuttle Looms

As most of us know, selvedge or “self-edge” denim is denim that has self-finished edges. The self edge, besides for being aesthetically pleasing, prevents the fabric from fraying and unraveling and generally (but not always) is a sign of a higher quality denim.

Vintage Shuttle Loom

For the most part, selvedge denim are made on a vintage machine shuttle looms that fell out of favor for quicker and more efficient machines in the early-mid twentieth century. These machines are currently enjoying a resurgence in popularity as more people become selvedge conscious.

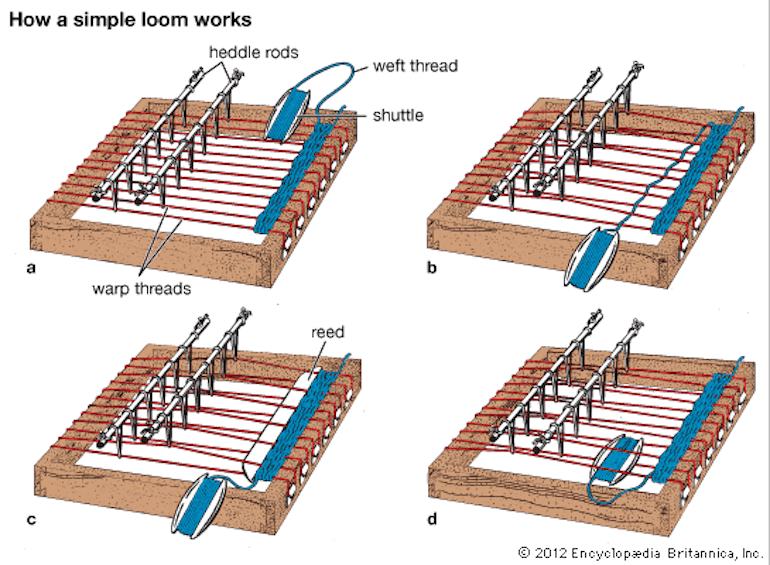

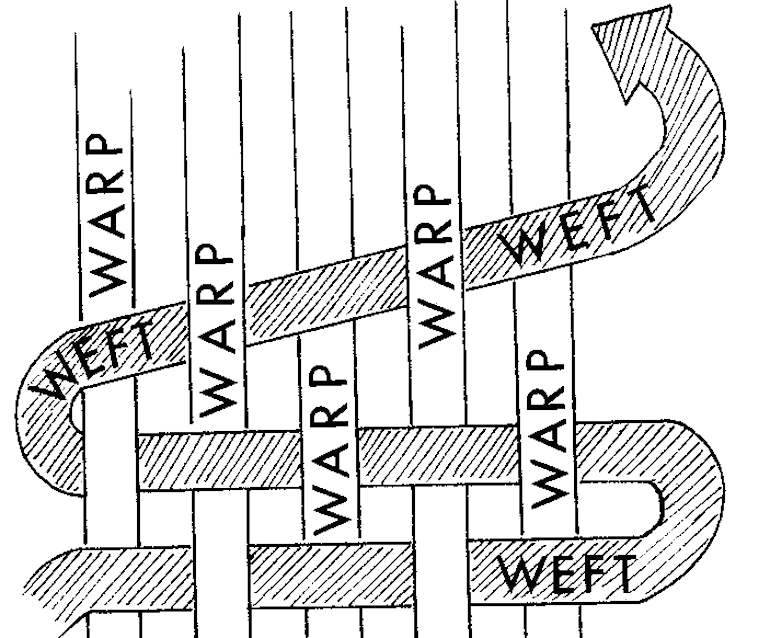

How the shuttle loom works is simple in concept: warp yarns (the vertical yarns) are set in the loom, the pattern is programmed in, and a shuttle carrying the weft yarn (the horizontal filler yarns) is shuttled horizontally across the loom which is then beaten together with the warp yarns to begin creating the fabric.

The shuttle makes numerous continuous passes back and forth with that single weft yarn which is what creates the finished edges. Most of the time, the mill creating the fabric will use white or natural warp yarns along with a single colored yarn at the edges of the fabric and the result is the colored selvedge lines that are so revered now.

Shuttle looms were the industry standard for quite a while and during that time almost all denim was selvedge denim. One of the challenges faced with using these looms is their slower speeds. A traditional shuttle loom can produce on average about 150 picks (rows of weft yarns) per minute.

As technology progressed and consumer demand for denim grew, companies began favoring machines that could weave fabrics at those much higher speeds. Several types of looms came about as improvements upon the shuttle loom with the projectile loom being one of the most common for denim manufacturing.

Projectile Looms

The projectile loom does away with the shuttle and instead shoots the weft yarns across the warp one row at a time that work in sequence to form the fabric. The high level explanation of how the loom operates is also simple: the warp yarns are still set into the loom but instead of a shuttle, there are multiple smaller projectiles that grip onto the end of the weft yarn and shoot it across the loom through the warp yarns.

When the projectile reaches the other side, it releases the yarn and drops down to a conveyor belt which then transports the projectile back while another projectile shoots across the loom. This rapid fire sequence can produce well over 1000 picks per minute, and that’s on a textile that’s often twice as wide.

Because the projectiles don’t loop back around with the weft yarn when it reaches the other side of the loom, the weft yarn is cut at the edges of the fabric thus leaving the ends of the fabric frayed and unfinished. Later, an overlock stitch is used to secure the edges of the fabric on a finished garment which is a defining feature of non-selvedge denim.

Overlock stitch on a pair of non selvedge jeans

Non-selvedge denim can differ from selvedge denim in many ways but often times, it’s not just due to the fact that it’s made on a projectile loom and is instead a combination of many factors like how the yarn is dyed, cotton used, weight of fabric, speed in which the fabric is made, etc.

Projectile looms themselves don’t inherently make lower quality fabric, there actually are plenty of mills making fabrics on projectile looms that can be comparable to some selvedge fabrics. It’s just that most mills are more focused on volume rather than quality and so they use the much faster projectile looms to fulfill that goal. For a more visual representation, check out the video below:

Obviously, there are many complexities about shuttle and projectile looms and how fabrics are made that went unmentioned here but hopefully with this baseline knowledge, you will able to dive deeper with all the details there are to know about looms!