Japanese denim brands are well-known for their obsessive attention to seemingly inconsequential detail. But the exact process by which this is done often remains somewhat obscure to overseas clientele, who rarely get much of a behind-the-scenes glimpse of denim production, aside from the occasional pictures or videos of shuttle looms.

That’s why Japanese brand Workers‘ new six-part feature From Cotton To Jeans is so insightful. Lavishly photographed and well-documented, it might be the most detailed look yet upon the processes involved in making a high-quality pair of jeans – from selecting the cotton, to spinning and weaving the yarns, all the way to the finished product.

The amazing documentation, however, was entirely in the Japanese language. We’ve taken the time to translate all of Workers’ text into English and reproduce it here so it can be appreciated by a western audience. In this first section, Workers travels to Tennessee to pick out cotton for their jeans. Enjoy!

Part 1

These posts will show the processes involved in creating jeans for Workers’ Fall/Winter collection, starting with the cotton.

Raw cotton

What type of cotton, from which country, is used in making denim? Are we aiming for the type of cotton originally used in mid-twentieth century American denim? That would probably be mass-produced, inexpensive American cotton. However, because of the influence of selective breeding techniques used in agriculture, this cotton isn’t really the same as in the past.

Therefore, amongst American cotton, the most basic type is called Upland Cotton. It’s cotton taken from the EMOT region – Eastern Memphis, New Orleans, and Texas. We go to Memphis to see what this cotton is like, from its growth to its final shipping.

Memphis is where cotton sales take place, although the building where cotton was once sold on the market is now a museum. In the present day, cotton sales are mostly made in other cities like New York, via electronic means.

In this thirty-year period the cotton industry has undergone impressive change. On the Mississippi River only a few minutes’ walk away, a tourism boat conceals the bustle of past times.

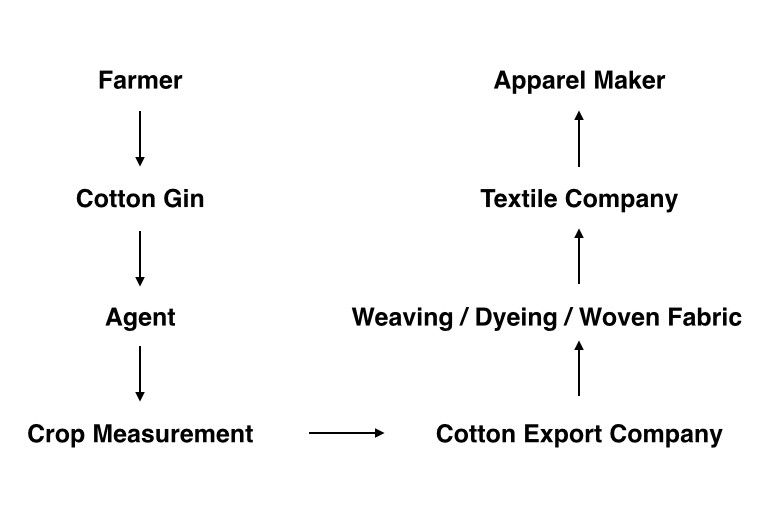

The Production Stages

When we first think about using this kind of cotton for our denim, we consult with the textile company. Normally, what happens after that remains confidential, but Workers wanted to see the entire process.

As you might expect, we were told that this was the first time a Japanese apparel maker had followed the farmers, measuring process, and agent.

The most surprising thing about American cotton fields was that cotton, wheat, and corn were grown alongside each other on the field. In order to have a stable income, the farmer always controls the planting. In the photo above, a machine called a Picker is used to harvest the cotton, and on the right you can see the box-like, hardened shape of the harvested cotton bale.

On the right side, an agent specializing in cotton walks past the harvest. He buys the cotton from the farmer and sells it after measuring the crop. All of the machinery used to harvest cotton is specialized for each purpose. Because of the high cost of cultivating cotton, many farmers shy away from planting this crop.

The cotton is taken to a facility called a gin, where the cotton and seeds are separated. The cotton is transported in hardened bales. Once, this process was done by hand, but with the invention of horse-drawn gins and other technology, the modern process is almost entirely mechanized. After the packed cotton is sent to a storehouse, it is shipped out.

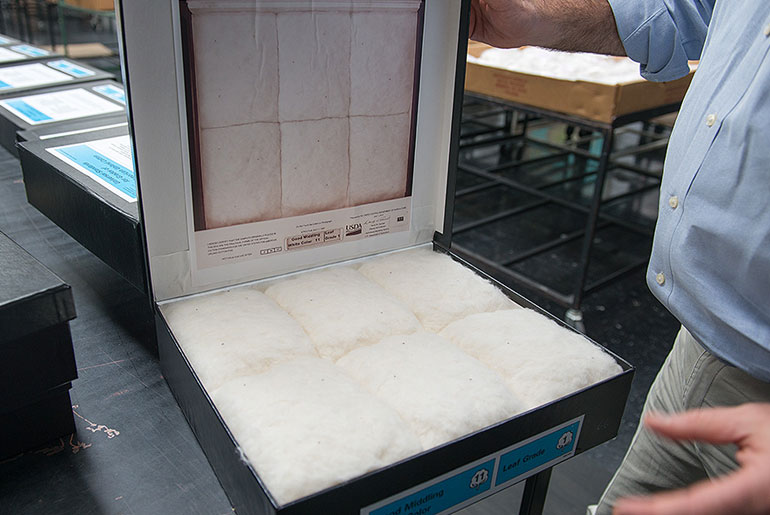

After the cotton is purchased from an agent it is measured for trade with Japan. The grade of the cotton is evaluated in the Classing Room, by machinery which grades the quality of the cotton. The measurement process isn’t just for the Japan, but is also used in the US when cotton is sold to spinning companies.

Check in soon for Part II of Workers’s series From Cotton to Jeans, which covers Combing and Spinning. All text and images courtesy of Workers.