For anybody looking to get into DIY projects such as hemming, tapering, and repairing jeans, and even making finished garments and miscellaneous small projects, a sewing machine is essential, but finding the right one to start with can be tricky. Very few sewing machines made today for a reasonable price work well with denim or canvas.

The best way to go if you are looking to keep things between $25-150 is older, used machines. Generally, older domestic machines in working condition are readily available in the secondary market. However, there is not one specific machine that I could recommend to you to start out on. This guide will show you what to look for in a machine that will work well with denim, canvas, and other heavier materials, without stalling, jamming, and requiring minimal maintenance.

Great example of a beginner’s sewing machine. There’s a decent amount of room to maneuver pieces in, and the controls are straightforward (stitch count is the only thing to adjust). Additionally, everything you will need to oil is easy to access either through holes, or it is exposed. The faux snakeskin box and golden Sphinx don’t add anything functionally, but look pretty great.

Where to Buy

To start off, you need to know where to look first. In my opinion, the best place to start off is asking family. This comes with the added bonus of having their knowledge to help you as you start off. If family isn’t an option, your next best bet is going to be things like garage sales, estate sales, and second hand stores. These all give you the option of inspecting the machine pretty well, including plugging it in and running it for a second to see if there are any obvious electrical problems.

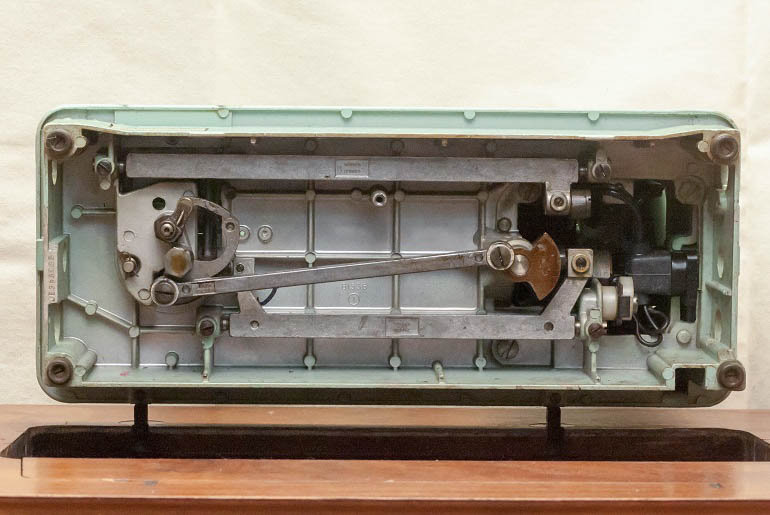

Underneath, everything you will need to clean and oil is all there, and most importantly, everything is metal.

Finally, there is the internet. Sites such as eBay, Craigslist, and Kijiji (for those up north) will have a large selection of used sewing machines. Often, these sites list things local to you, which gives you the opportunity to try before you buy. Be wary of having things shipped to you though, as there is no way to get a good look at the machine other than from pictures and asking the seller questions. These may not tell the full story. There are, however, good machines to be had from all of those websites, just proceed with a little caution.

Now that you know where to look for a machine, you will need to know what to look for in a machine.

From behind, everything is also exposed. This will allow you to change the belt easily. The large hand wheel is a nice feature as well, this will make things easier when going over multiple layers of fabric. Overall, 9/10, since there is no reverse function.

The Machine: General

In general, older machines will be better, but this is not always true. When looking at a machine to buy, you are going to want to look out for metal components, the more the better. Take a look underneath and inside to check for plastic on anything that moves.

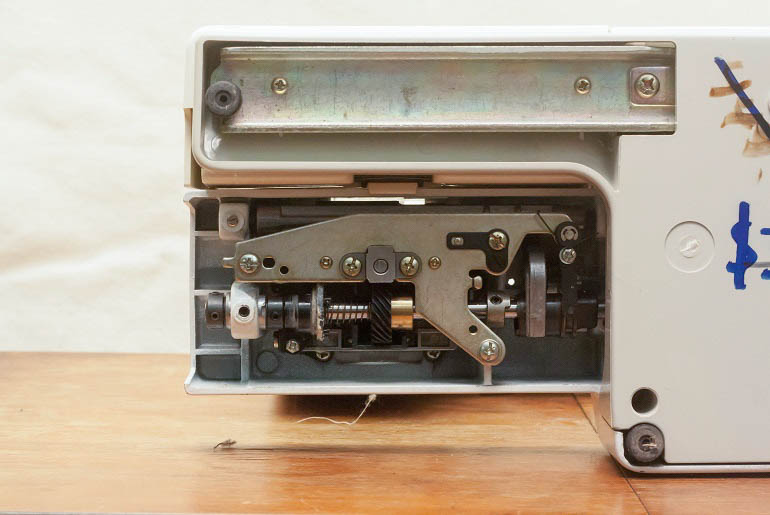

Another great beginner’s machine. There are a few more functions than the previous machine, and a little less room (but still enough) to move pieces around on the bed. Also, you may be able to see that you will need a screwdriver to get at some points to oil.

Plastic will be much more prone to failure, especially when sewing heavier materials. Any obviously broken parts, rods, shafts, gears can be fixed, but repairs can get expensive. If you are just starting out it is best to avoid the hassle and buy a machine that works right off the start. Ease of access for cleaning and oiling is also important. You should not have to undo more than a couple of screws to get inside the machine, and when looking inside, look that it is fairly simple and uncluttered.

Underneath, there is only one screw to get at the internals, and the cover does help to keep the dust away.

Inside, everything is pretty simple, and again, everything that moves is metal.

For sewing materials like denim and canvas, especially if you are planning on eventually making whole garments, you are going to want a more powerful machine. Visually, size is a good way to judge this. Larger is generally better. If the machine is driven directly instead of with a belt, that is also better, but direct drive is not essential. If you cannot find a powerful machine, it is not a big problem, you may just find that you need to use the hand crank to go through seams with many layers of fabric.

Looking in the back, things are a little cluttered, but none of the moving parts are plastic. 8/10 overall, as a machine like this lacks a little in size and power.

If your main goal with this machine is to do repairs, a larger bed, and more space between the arm and the bed will be helpful. Maneuvering a whole garment on a smaller machine is doable, but more space is ideal.

The Machine: Functions

Simple forward and reverse straight stitches are enough for all of the above projects. Reverse is not essential, but it is nice to have as it makes machine darning and back stitching (which is used in tapering and making whole projects and garments) much easier and faster, as there is no need to stop work, and turn the piece you are working on in the desired direction every time you need to do so.

This machine is a little more typical of what you may find second hand. Lots of plastic, lots of functions. Not a whole lot of room to move pieces around.

Functions on a machine such as zig zag stitches and buttonholes can be useful, but are not essential. Zig zag stitches can be used to make a quasi bar tack, but straight stitches can be used with little to no functional difference. The zig zag function can also be used as a way to overlock raw edges, but you could do a taped seam for a cleaner look and without the zigzag function. The buttonhole function can save time when making jeans or other garments, though buttonholes can be hand sewn by hand, and with some practice will look better than those made with a multi-function machine.

Underneath, there are a couple of screws to get to the internals.

Inside, many of the moving parts are plastic, which is much more prone to failure than their metal counterparts.

Things to Avoid

When testing out a machine before buying, there are some things to check for that will help you avoid problems with the machine in the future. If the pedal, motor, or plug become hot to the touch after little use, this indicates some form of electrical problem, and that the machine will eventually need work done on it. Another problem that tends to come up, especially on older machines is the bushings in the motor get worn out. To check for this, look into the motor as the machine is running. Sparks mean there is a problem which will eventually need work.

In the back, there are even more failure-prone plastic parts. The hand wheel is also tiny, so thick seams will not be fun with this machine. 5/10 overall, as this machine will still work (and it’s what I started learning on), though it is more prone to failure and jamming up, and the small bed can be difficult to work on at times.

Things such as electronic settings and embroidery functions, while not necessarily bad, are not particularly useful. Things past your basic straight and zigzag stitch can end up being one more thing to go wrong.

Closing Thoughts

Well, congratulations, you just bought your first sewing machine! Your work is just starting though, and some things may need to be adjusted before you really get into it.

- If there is a belt, it wouldn’t hurt to change it. If a machine has been stored for a long period of time, the belt tends to stay in the shape it was stored in. I have noticed that this can lead to the machine stitching a little inconsistently.

- Your new machine could also probably use a good cleaning. Canned air works well to get rid of any thread fragments and dust, followed by a dry rag to get rid of any old dirty oil is enough to start with.

- Before starting and after cleaning, you should oil the machine. Use sewing machine oil wherever the manual says to, or, if there is no manual, oil every moving part under the machine, under the faceplate, and in any holes the burette from the oil bottle fits in.

- Finally, if you bought a used machine that came with some needles, set them aside and buy some new ones specific to the material you are working with. Cheaper needles tend to dull and break much faster than nicer needles. Schmetz is a good, safe bet.

Good luck, and happy sewing!