Selvedge denim is produced worldwide, but in the denim enthusiast community, Japanese denim is often praised above the rest. Many denimheads consider Japanese fabrics to be the best of all – but what, exactly, makes Japanese denim stand out in the minds of so many when compared to American, Italian, or Turkish denim? Is it all just hype, or are there real differences that give Japanese denim a unique edge?

The answer is, honestly, not necessarily. Not all selvedge denim is created equal, so while most selvedge denim is high quality, that selvedge line doesn’t automatically mean that it will age in a distinct manner or wear well over time. Denim produced on a Japanese selvedge loom can have radical variations in color, weight, and texture from one fabric to the next. By understanding how different characteristics affect denim’s aging, longevity, and appearance, you’ll be better equipped to find the right kind of denim for you and judge the quality of any particular denim.

Texture

First of all, Japanese denim is often made on old shuttle looms – not American Draper looms imported to Japan (as is sometimes thought in popular myth), but vintage Toyoda looms. When the Toyoda Model G was introduced in the 1920s it was a major advance for fabric weaving machinery, creating such loyalty that looms descended from the 1924 models are still used today by Japanese mills. Vintage Toyoda looms make fabric in very limited quantities – the typical roll of denim will be a little under three feet wide and the weaving processes is much slower than on modern machines.

Modern looms, in comparison, are very fast and efficient plus make a precise and consistent fabric. The thing is, experienced denim fans don’t want precision – it’s actually the variation and imperfections of the weaving process that lend character to the best Japanese denim.

When comparing a nice sample of Japanese denim to a typical off-the-shelf pair of jeans, you’ll immediately notice the difference in texture – most jeans have a smooth surface, but Japanese denim is often surprisingly hairy or rough. This can often be quite intimidating at first for someone used to wearing soft, pre-faded jeans. Pure Blue Japan is renowned for its slubby fabric, faded Samurai denim has a complex, grainy texture, and The Flat Head is known for its heavy vertical fading. These qualities are accomplished by modifying the looms to chatter as they weave, creating a unique texture. Such brands often keep their exact weaving methods a carefully-guarded secret, such as Oni.

In contrast, selvedge looms set up to weave an even, neat roll of denim can produce a fabric that (aside from the selvedge line) is virtually the same as non-selvedge projectile denim. It’s worth learning as much as you can about the denim on a pair of jeans before you buy in order to determine what the fabric has to offer beyond a selvedge line. Just because a fabric is selvedge or even made in Japan doesn’t mean that it’s better than any other denim.

Color

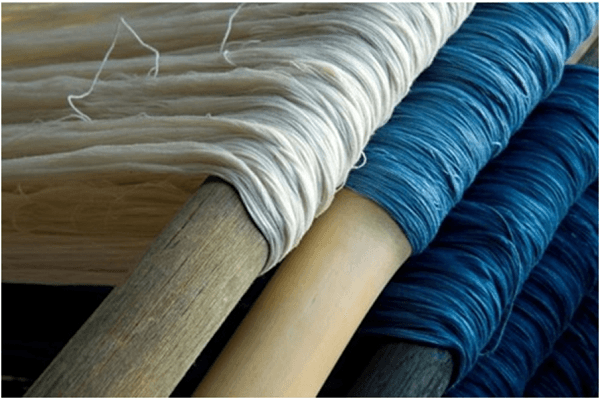

The dyeing process is traditionally a crucial ingredient in giving the best Japanese fabrics their flavor. Japan has a rich history of textile dyeing, dating back to kimonos from hundreds of years ago, a technique preserved today in techniques like kasuri dyeing. Likewise, Japanese denim is created with a variety of different proprietary dyeing processes.

One of the most striking properties of Japanese denim is the variation in color from one brand to another. While many recent Western brands use the same (admittedly high-quality) Cone White Oak selvedge denim on their jeans, this means that one pair will fade very similarly to the next.

On the other hand, the faded color of Japanese denims can be dramatically different from one brand to the next. Some brands, like Fullcount, Denime, or Warehouse excel in reproducing vintage American-style denim with a lighter overall color. Brands like Tenryo, The Strike Gold, and Pure Blue Japan produced dyed weft fabrics to give their denim unique fading properties, such as a gray or brown overcast. The Flat Head and Eternal use an extra-dark dyeing process to create denim that fades to a rich turquoise blue over time.

Weight

Another element of Japanese denim is the weight. While Japan produces plenty of lightweight fabrics, most denims of 20 oz. or more comes from Japan. Comparatively, most other types of denim weigh between 11 and 14 oz.

While weight is largely a matter of personal preference, the added durability of a heavyweight denim makes it appealing to many denim enthusiasts. Besides the additional toughness and warmth in cold weather, heavyweight denim tends to give thicker creases, and thus often faster or more defined fading than lighter materials. However, just because denim is heavyweight, doesn’t mean that it will be longer-lasting than regular denim. Heavier denim puts more stress on the stitching, which can lead to faster thread breakage in some cases, especially on jeans with all-cotton stitching.

Processing

Another important factor in giving denim its character is the post-weaving processing involved – or a lack thereof.

Sanforization is the most familiar process, by which unwashed denim is “shrunk.” While unsanforized denim will experience considerable shrinkage from washing, sanforized denim usually doesn’t shrink much. Sanforized denim generally lasts longer than unsanforized; the main tradeoff being that it fades in a much softer manner, and high contrast doesn’t come as readily to sanforized denim. Sanforized fabrics are softer and smoother than unsanforized when new.

Singeing is the process by which the loose, hair-like fibers on the surface of the denim is burnt away, contributing to a smoother feel. Like sanforization, this process is extremely common on mass-produced denim. Most large companies are concerned with producing a fabric that’s immediately soft and comfortable. However, many high-quality raw varieties of denim are singed as well, such as some of R.J.B.’s fabrics.

Calendering – Calendering is a process where denim is evened out by passing through heavyweight rollers. Heat and pressure create a smoother, more comfortable fabric. Calendering contributes to the uniform appearance of most denim, like the other processes.

Mercerization – This process involves soaking the fabric in a chemical solution, which causes the fiber to swell. Mercerization also gives the denim a smooth sheen. It’s one of the final processes the denim undergoes.

Although many Japanese mills make fabrics with all of these processes, the high-end artisanal brands like Strike Gold and Studio D’Artisan, among others already mentioned, forgo these processes completely. This is called loomstate denim, and a few Japanese mills are among the only places in the world where true loomstate denim is still commonly produced.

The manner of processing can have dramatic ramifications for the feel, durability, and aging potential of a pair of jeans. For example, a pair that’s been sanforized, singed, and calendered, such as 3Sixteen’s SL-100x or Iron Heart’s 634S, will be comfortable when new and won’t need to be soaked before wearing. The wearer can enjoy a raw pair of jeans that will have a unique shine before the first wash, and if well-maintained the denim will last for a long time due to the even composition.

The smooth, more even texture of sanforized denim.

By contrast, a pair of loomstate jeans, such as Samurai’s S710xx or Flat Head’s 3005 will have a much rougher, hairy, and uneven feel and appearance. These jeans can be harder to deal with, between trying to correctly determine your size and effectively shrinking to the proper size, and the less uniform nature of the denim can make it less durable than sanforized fabrics. However, the payoff is a sharper, more defined quality to the creases and points of stress, as well as a more textured appearance to the denim.

Unsanforized denim, uneven, sharper texture.

It’s worth pointing out that just because denim is Japanese, there is absolutely no guarantee that it will have these characteristics. Many Japanese fabrics are sanforized, treated, and have a less complex texture. Just because a brand boasts that their fabric is made in Japan, there is no certainty that it will have any of these qualities. The best Japanese denim is distinguished by the indigo dyeing processes, the weight and weave of the denim, and the texture of the final product. All of these factors contribute to a pair of jeans that is designed to show optimal evolution over time.

It’s this combination of qualities that give Japanese denim a unique character rarely seen on other fabrics. While other denim mills are quite capable of producing denim with similar qualities – particularly when it comes to forgoing post-weave processing – most are more concerned with speed, efficiency, and consistency. By re-discovering the virtues of a rough and unrefined fabric, other denim mills might one day produce their own fabrics rivaling the qualities of Japanese denim.

Particularly due to the rising interest in jeans made entirely in America, Cone Mills has experienced a resurgence of activity; however, their denim is mostly sanforized and undergoes other processing. Last year, however, the mill introduced their first loomstate fabric in over sixty years, made exclusively for Roy. Perhaps someday soon, some enterprising individuals would be willing to start their own denim mill on American soil, dedicated to special batches of artisian denim on the same level of uniqueness as Japanese fabrics.