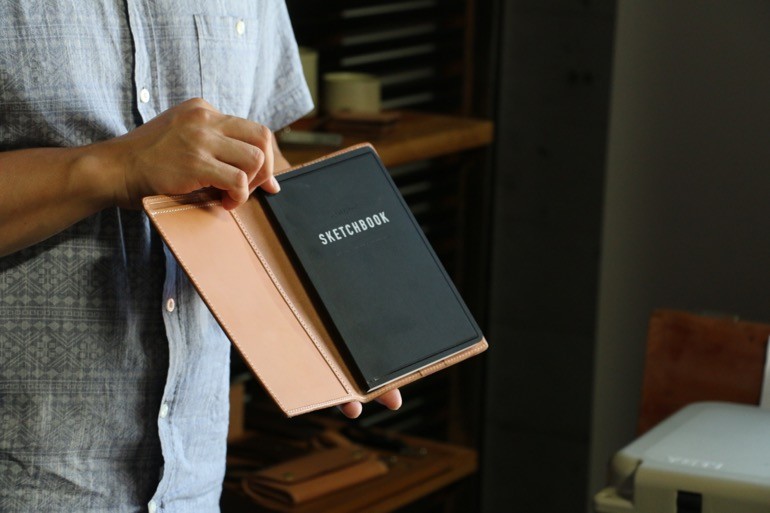

Leather and accessories brand Tanner Goods has had to relocate several times since the company’s inception in 2006. As their selection of belts, bags, and wallets grew to fill two retail stores and over a hundred stockists worldwide, the production side had to swell to keep up. In just nine years, they’ve gone from founders Sam Huff and Jevan Lautz to thirty employees.

After outgrowing their previous home at Portland, Oregon’s Leftbank building, Tanner now has their own warehouse in an industrial park just east of downtown. We had the opportunity to tour Tanner’s new home, which houses pretty much all of Tanner’s operations outside of retail sales.

Tanner’s success isn’t just due to the quality of their product, it’s the result of planning and logistics that have allowed their products to scale while retaining that same level of quality. They’re making artisanal leather goods, but it’s run like a tech company.

Tanner’s still producing with the old ways–clicking hides by hand, saddle stitching wallets, hand burnishing the edges of belts–but they’re using modern inventory and production systems to make sure that work is done in the most efficient way possible.

The Kanban system in action in Tanner’s store room.

Tanner produces nearly everything in house, has over a hundred accounts, ships direct to consumers, and runs private label production for other brands. That means inefficiencies can build up quickly and they’re always looking for ways to trim down and simplify.

The newest system they’ve implemented is a Japanese stock-keeping method called “Kanban”, which makes sure production always has a reserve of what it uses most. And while no one could completely explain the exact translation of the name, Kanban has cut down drastically on fulfillment times for almost all of their online orders.

One of the most striking things about the tour was the age of their workforce. Pretty much everyone we encountered was in their 20s and 30s, a complete rarity as most of the people with the skills to make high quality accessories and apparel were trained before that work left the United States in the 1990s.

Previous experience is preferred, but Tanner also trains on-site for people who want to sew, glue, and stamp. We’ve written before about the problems with the greying of specialized labor, so it’s refreshing to see a company that’s willing to invest in training a new generation.

Their clicker die cuts almost non-stop. They through an estimated 50-60 full leather hides a week to keep up with the rest of Tanner’s production.

Workshop visits are only available by appointment, but you can find all of Tanner’s products at their retail stores in Portland, Los Angeles, and on their website.