If you leave here without knowing anything else, know this: Zachary Brown of ZeeBee Leather is a quality obsessed craftsman. He agonizingly scrutinizes every detail of his work to the point that on at least one occasion, Brown has scrapped a piece with a flaw after 11 hours in. But that level of effort exemplifies why Brown is becoming of the best options for custom leather work in the US.

Brown admits, “There are some workmanship flaws that can be worked out, but if I slip with a stitching groover, or gouge the surface of an otherwise pristine piece, it’s over. I try to handle the leather with respect and let the end user beat the crap out of it.”

After falling in love with a pair of Wesco Boots seven years ago, Brown became hopelessly obsessed with quality. “It devolved from there,” Brown says. “I began looking at everything with a very careful eye.”

He would soon embrace the cult heavyweight denim brand Iron Heart along with their forum. He loved the relationship the internet enabled him to have with the people who made his clothing. He could give feedback and see it implemented, which struck a particular chord with him.

Professionally, Brown has over 20 years of experience in the culinary world. He’s also a Chief Petty Officer in the Navy, where he enlisted about ten years ago, when the typical restaurant gig left him disenchanted. The combination of honed hand-eye precision, discipline, and DIY gumption eventually lead him into leather working. He explains:

“…When I started looking for a proper knife roll, I was coming up empty handed. So much made in China crap out there. I decided to make my own. I also needed a phone case and figured I could make one for myself as well…

“When I first got started, I asked a leatherworker I admired for some advice and he was very reserved. Artists can be like that. I really try hard not to be. I’m very open with my knowledge and I love to help people starting out. I’m not worried about people cutting into my business because they won’t. All they’ll do is strengthen the craft and broaden the scope of what leatherworkers do. We all have something unique to offer.”

It’s been three years since Brown took the plunge into leatherwork, and he’s proven to be quite good at it. His knife roll into a thing of beauty and he’s expanded his lineup of goods into a healthy variety of belts, bags, cases, and holsters. People took notice, and it wasn’t long before he had an organically created list of customers. The Iron Heart forum also put him in touch with his first retailer, the UK’s NoKipple.

“Gavin Smith and I are old friends from the Iron Heart Forum, and when he and Jon (Joseph) started NoKipple, I got thrown into the mix,” Brown said.

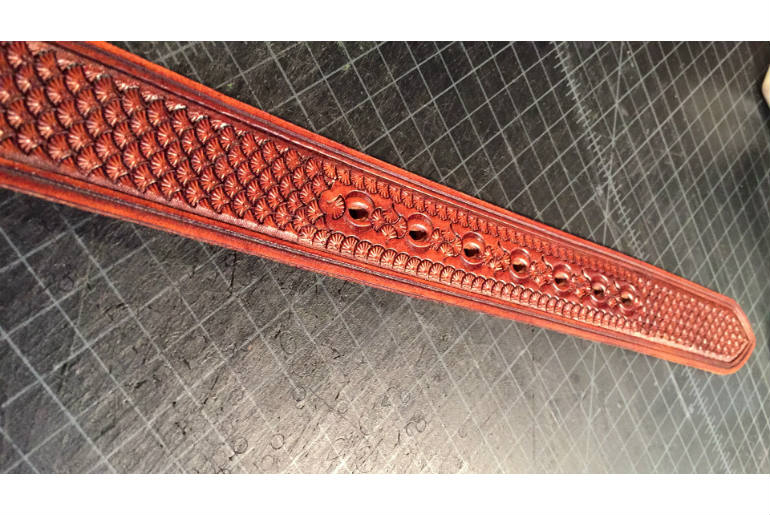

NoKipple, since its inception, has specialized in bringing to market less common goods of high craft and durability so it’s no surprise that they would want to stock their talented leatherworker friend. ZeeBee’s offerings in the shop are limited to a cell phone case and a belt, but not for lack of interest. A single belt can take over twelve hours alone, so he limits most of his production time to custom orders.

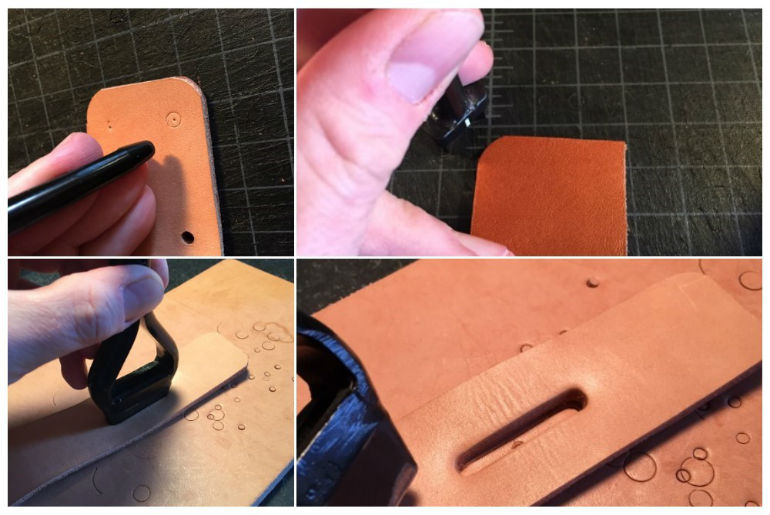

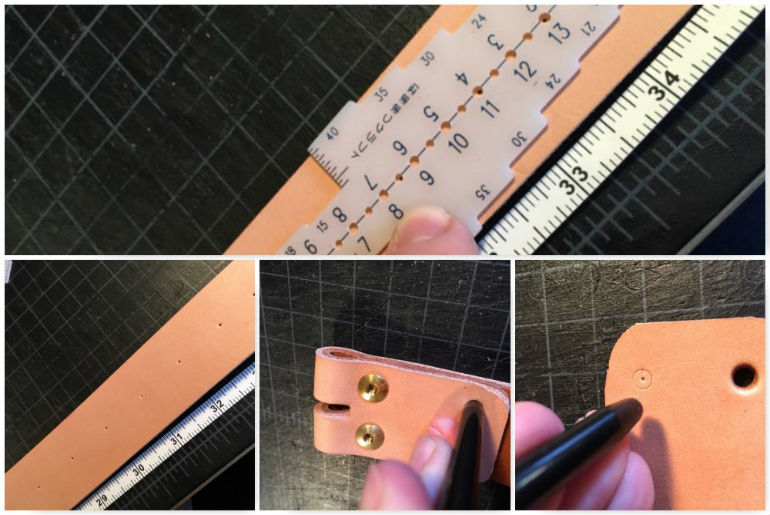

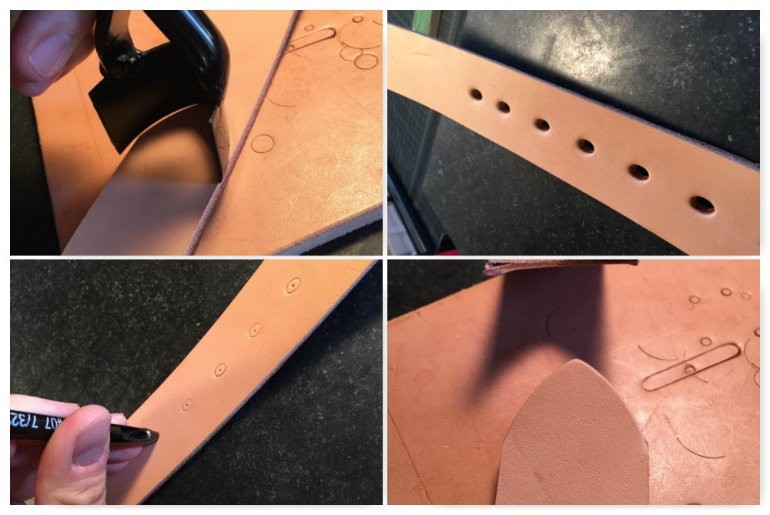

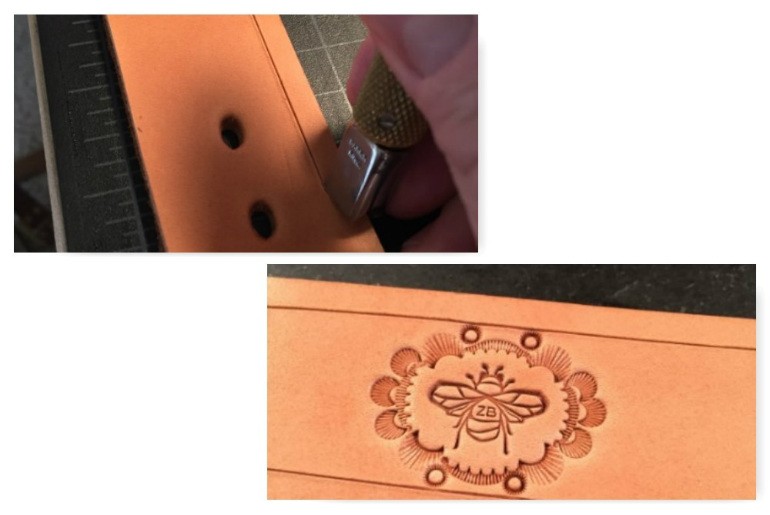

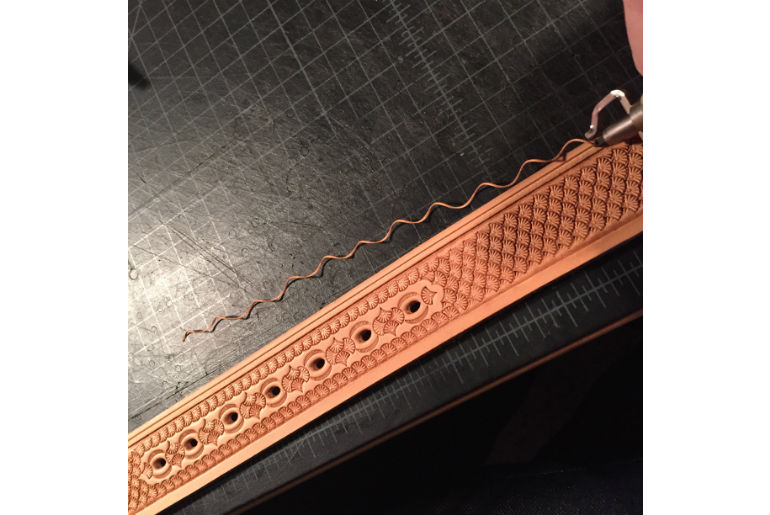

How It's Made - See a Belt from Start to Finish

Brown continues,

“I used to be really into a very large well known leather company, but after learning more and more, I’ve found their goods to be really low quality. People want stuff that will really be heirloom quality… The [belts] I’m currently working on have about 8 or 9 hours already. I still need to stitch and burnish so we’re looking at almost 5 more hours. These belts are tooled though, so need more planning, prep, and attention.”

One such belt that Brown was referring to is the one highlighted above. He is an ultimate example of someone who refutes modern technology to streamline his process. Everything is completely handmade he explains,

“I really don’t ever want to take shortcuts, and I feel like a sewing machine is a huge shortcut in leather craft. In order to truly make things that will last forever, leather goods need to be saddle stitched. Period.”

But Brown goes beyond refuting the sewing machine. For example, instead of using more modern hand tools like a skiver, he’ll use a razor-edged knife that he can shave the leather of a belt or otherwise gradually and precisely. If he wanted, he could shave the leather paper-thin. These methods lead to a great intimacy with every item that he’s making, and as a consequence Brown can create goods you’ll never see on a mass production level.

Since each item is custom, Brown takes the process one step further. After selecting the original design pattern (belt, bag, phone case, etc.) everything else is generally open for discussion. Brown seems to like a challenge, so if you have any sort of idea for a leather good, chances are he’ll give it a listen. Recently he created a briefcase to test his limits, a project that took 70 hours without including design time. And while he hasn’t tackled footwear or jackets yet, he’s eager for the opportunity.

If you haven’t noticed yet, all this adds up to goods that can be cost-prohibitive for many consumers. A true saddle stitched belt, which combines two separate kinds of leather from Horween and/or Herman Oak, starts at $275. Add hand tooling and you’re looking at $350. The aforementioned chef’s knife roll will run you $750. And his bags? Over $2,000.

But Brown isn’t worried about sticker shock. Take everything into consideration and what Brown is charging isn’t quite as exorbitant as you might initially believe. Based off his work hours alone, Brown is charging anywhere from $15-40 an hour for his product. This doesn’t take into account any of his other costs that he incurs, which include purchasing raw goods, maintaining his web presence and customer service.

To put that in prospective, Kyle Rancourt said, during a 2013 Reddit AMA that Rancourt & Co., a well-staffed shoemaker, paid its shoemakers at least double minimum wage, which would be at least $17/hour. And that’s not working purely by hand. Considering that ZeeBee Leather places a lifetime guarantee on its goods, to go along with the quality that it sets forth, Brown is well within the sweet spot of being reasonable for how he values his labor.

“I don’t really care if I’ve priced myself out of the majority of budgets. I’m not going to compromise on quality. As I said, I’m quality obsessed. You can’t find hand-made briefcases on the market because one, they’re incredibly time consuming and two, they’re expensive. I offer a niche in that regard.”

A niche that is happy to have him.

To learn more about ZeeBee Leather, checkout the label’s Website and Instagram.