The Quint Hat has been reborn as Quint’s Revenge. Pick one up in the Heddels Shop now.

This is the second iteration of our CO-OP series, our collaborations with brands we admire to create limited runs of specialized products exclusively for Heddels readers. By working with the brand, we hope to dive far deeper into who they are and how they operate than we ever could have with a profile. We have an extensive list of rules that we have to abide by for each product to bear the CO-OP label.

Our CO-OP articles serve as the complete documentation of how we created our product, from concept to sales. This one covers the creation process with Brooklyn brand Knickerbocker MFG on our second product, the Quint Hat.

Unworn on the left, 6 months of wear on the right.

Why Knickerbocker

I moved from Denver (the site of our last CO-OP) to Brooklyn last fall. I already knew many brands in the New York area through the trade show circuit, but I felt a particular affinity towards Knickerbocker. They seemed to be always on the cutting edge of new fits and fabrics and had an endless hunger for the authenticity of the past.

Like many of the brands I identify most with, Knickerbocker started as a hastily conceived idea and just never failed. In the world of vintage and vintage inspired design, I’m pretty much always the youngest person in the room at 26. Andrew J. Livingston aka AJ founded Knickerbocker when he was 20 (he’s 24 now).

AJ was a business student at NYU who had cut his teeth in clothing production as a semi-pro snowboarder in Southern California. He had more interest though in the tech packs of the brands that sponsored him than in tech decks and he moved over to the design side of the business.

In 2011, he was looking for a production company in the city that could make small runs of hats for his eponymous streetwear brand. What he found was an old ballcap factory on the border of Bushwick and Ridgewood in North Brooklyn. The owner, Michael Pellet, used to make hats for everyone from Major League Baseball teams down to the MTA, but offshoring had almost completely dried up his business. AJ was one of the few customers that had a small enough order to make it in the States.

As Pellet was ready to retire, he had no heirs who wanted the factory and couldn’t bear the thought of it going to condo developers. Pellet made AJ an offer he couldn’t refuse: fifteen grand for all the equipment and supplies in the factory plus a lease on the ten thousand-plus square foot space itself. Thus, the Knickerbocker brand was launched with a Kickstarter in May of 2013.

Since then, the Knickerbocker brand has expanded into a full range of apparel and accessories sold all over the world, the vast majority of it is made in that same factory in Ridgewood. Hats remain at the core of their business. The space serves as a collective to a host of other brands including Upstate Stock, d’emploi, Slightly Alabama, and many others.

I’m a big supporter of people who make it themselves. They can handle small runs, make changes on the fly, and know their product better than anyone. It’s also much more difficult to manage your business, and I have a great respect for those that can make it happen. Knickerbocker does just that and they were right in my new backyard. It seemed like a perfect fit.

The Inspiration

I watched Jaws for the first time when I was seven years old.

I already had a strained relationship with the water. My parents enrolled me in sink-or-swim style swimming lessons when I was three. I would hide in the bathroom and feign illness, waiting in abject terror for Penny, the instructor, to grab me off the toilet and throw me in the deep end. Penny didn’t complain though, she empathized. Later she would tell my apologetic mother, “Don’t worry about it, he’s the only one here that understands water could equal death.”

If I got that feeling on my own, then Jaws democratized it for everyone else. The movie made the water into a nightmare. It’s that same sensation you get when you turn off the last light in the basement and scurry up the stairs before an unseen hand grabs you back into the darkness. But in open water you’re also moving in slow motion, your senses are nearly useless, and you can’t breathe. I remember swimming laps at the neighborhood pool that summer and constantly glancing back to make sure a great white hadn’t materialized since the last turn.

My intense emotions for the movie then have transformed into a cult-like passion for it now. I watch it at the start of nearly every summer as Brody, Hooper, and Quint take to the sea to kill the shark. But we all know who really stole the show.

Sam Quint! The moonshine-swillin’, chalkboard-rakin’, USS Indianapolis-survivin’, captain of the shark hunting ship Orca is just the epitome of 70s cool (by today’s standards, it’s Hooper, but we can talk about that later). Robert Shaw’s performance created one of the most iconic screen characters of a generation.

One Halloween, I wanted to go as Quint. All the pieces of the outfit are fairly simple (check my Working Titles post for all three characters), but I could never find a hat that got it right.

It’s a brown waxed cotton cap cut in a five-panel style. And from the images, it looks like that fifth panel above the brim has two pockets on it separated by the center seam.

The brim is also way more malleable than your standard plastic, it’s got a floppy tented fold down the middle that’s in various states of bend throughout the movie. It also has two and only two parallel tracks of stitches around the brim.

If only I knew people who made hats, I could have one for myself…

The Idea

On a completely unrelated note, the Knickerbocker crew and I had an independent and original idea to make a brown, waxed cotton, hat with a floppy brim! It would be made in the five panel style, but the fifth front panel of the hat would have a split section for two pockets.

Those pockets would most likely be useful for open ocean fishing, so we decided we would call it the “Quint Hat” in honor of those pockets on the fifth panel. And good luck proving otherwise in a court of law!

J.J. Fecik (left) and Brian Blakely (right). The handsome geniuses that made this hat possible.

The main Knickerbocker crew I worked with over the course of the project was Production Manager J.J. Fecik, known around the shop as the happiest married 24-year-old you will ever meet (and I have to agree), and sales manager Brian Blakely, whose work ethic is only matched by his skill behind a chainstitch embroidery machine. These guys are a true dream team for a project like this, they really made it all happen, and I’m here just writing it all down.

Initial Designs

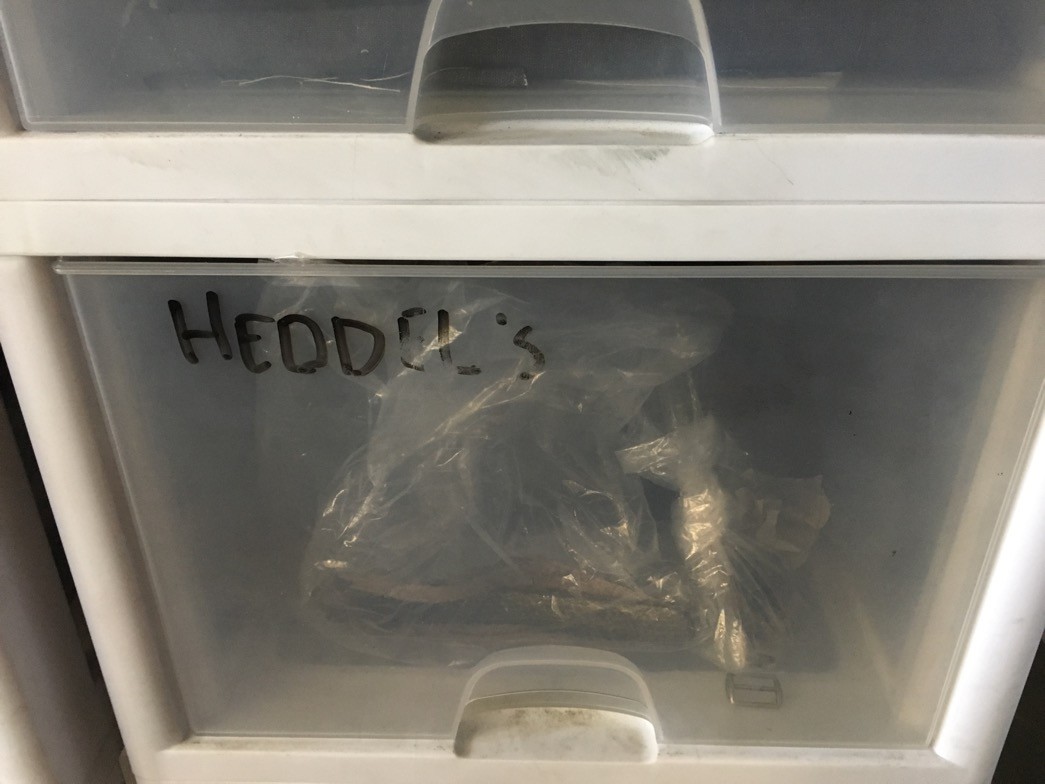

The cubby where our collab lived for the year we developed the hat.

As I’ve gotten deeper into the process with these things, it seems like there is a logical order to how you (or at least I) have come to develop them:

- Ideation – You have your idea and rough image of the materials it’s made from.

- Sourcing – You research the hell out of what those materials can do and where they can be found, requesting swatches, samples, and small quantities of yardage from whichever supplier will talk to you.

- Prototyping – Concurrently, you start making sample prototypes of your design with whatever approximate materials you have on hand to see if what you were thinking of actually works and iron out any kinks in those materials.

- Sampling – Once your design is ready to rock, you beg and plead and buy small quantities of the production material and make another sample out of those. Then you repeat step 3 with the production materials until you’re 100% comfortable with sending it into production.

- Securing – Then you buy the full production quantity of materials (or go back to step 4 if the preferred materials are no longer available), make another sample to make sure it’s all still the way you like it.

- Production – Then you cross your fingers and get it all made!

Knickerbocker had a whole host of material swatches on hand for us to choose from. We knew we wanted a waxed cotton canvas in a light brown/dark tan. Heavy, but not too heavy.

The initial swatches we looked at were a Shelter Tent canvas from Fairfield Textile. Fairfield has been producing and supplying waxed fabrics from their shop in New Jersey since 1838. The Shelter Tent is advertised at a light 8.25oz., but actually weighs in at over 10 once the wax is applied.

The waxed finish not only adds water resistance but it ages and patinas beautifully. After just a few months of wearing a sample, the hat had lightened, softened, and could be plied into any shape I so desired and back again. Check out version one!

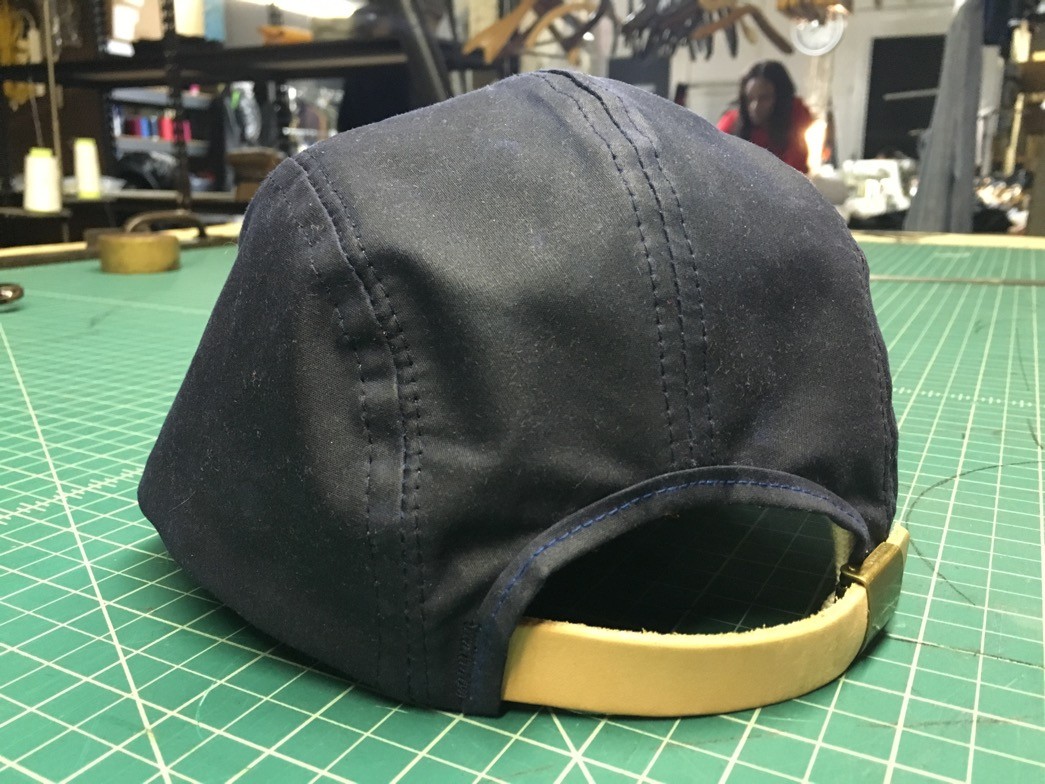

We cut our first sample from a navy version of the same fabric they had on hand. The floppy brim was made from layers and layers of stacked interfacing to give it that cool tent effect. The leather on the strap for this first sample was standard KMFG cowhide with a snap clasp closure.

Hey, who put these photos together? They clearly have nothing to do with each other!

We learned a few things from this sample. The natural twill tape on the inside left clean and sturdy seams. The fit and finish of the fabric was just about perfect. It was like the hat had a layer of armature in it, I could fold it into a ball and stuff it in a pocket and put it on twenty minutes later good as new. J.J. also nailed the silhouette on the first try. The shape is just dead on.

A couple things that needed changing though were the double stitches on the outside of the brim were too far out to effectively support its own weight, especially when wet. The master designer, J.J., was able to incorporate the front pockets into the center seam of the hat, but it didn’t look as *authentic* as what we were going for on the old style hats. The clasp on the back left a hanging edge of the strap that wasn’t as elegant or practical for a maritime-themed hat and the cowhide didn’t have that “x-factor” for the back strap to really make it pop.

With all the major hurdles of design out of the way, we were ready to move on to sourcing.

Material Sourcing

As mentioned, we were thrilled with how the 8.25oz. waxed Martexin fabric translated into the hat so we bought the yardage from Fairfield and had it on hand within days. The natural herringbone twill tape would work just as well as it did on the sample, we went with a tonal Efrid thread to match the brown, and swapped out the snap clasp for a brass slider buckle instead.

Everything came together quickly except for that back strap. There had to be a material that would match the narrative we wanted to tell.

I considered using shark leather, but after some very intensive research realized that doing so is unsustainable and marginally ethical. Shark populations have dropped drastically over the last few years and even though most of the leather is the byproduct of shark meat fishing (mostly for sharkfin soup), we didn’t want to glamorize the use of an animal that is quickly on its way to the endangered list across almost all species.

So I looked at other options, everything from shark-bite-proof webbing used on fishing trawlers, synthetic shark skin designed as an antiseptic surface in hospitals, and even upcycling old fishing rulers. That’s when I remembered a peculiar spot I visited in Reykjavik, Iceland about four years ago that was selling salmon leather. Yep, salmon leather. A quick google away, and I was talking to Silla Eysteinsdóttir, the sales manager for Iceland’s premier pescetarian tannery, Atlantic Leather.

Silla kindly explained the process of how Atlantic Leather takes the skins of salmon and other fish from Iceland’s fishing industry and tans them just like any other leather. No animal is killed purely for the purpose of using its skin at Atlantic Leather and the tannery even runs on renewable geothermal energy.

They could spin up perch, cod, and wolffish in a variety of finishes and salmon they could veg-tan. Even though the salmon is much thinner, it still has a tensile strength of over 20 pounds and has a depth to the scale pattern unlike any leather I’d seen before.

When the sample pack arrived, we all sided with the black veg-tan and put in an order for a dozen skins.

While we waited for the salmon to arrive, J.J. spun up another sample with the test fabric and our slight alterations. The stitches on the brim came in about a half inch and another line of stitches was added to the very end for stability. The front pockets were cut from a single piece of fabric and top stitched onto the front of the hat along with a bartack to help keep it in place.

And finally, we swapped the snap clasp for the band out with a brass slider buckle so the excess length could tuck back into the sweatband of the hat.

It was also around this time that I had the honor of getting stick-n-poke tattooed by Brian AND that I was featured in the Japanese magazine Men’s Fudge while wearing a sample version.

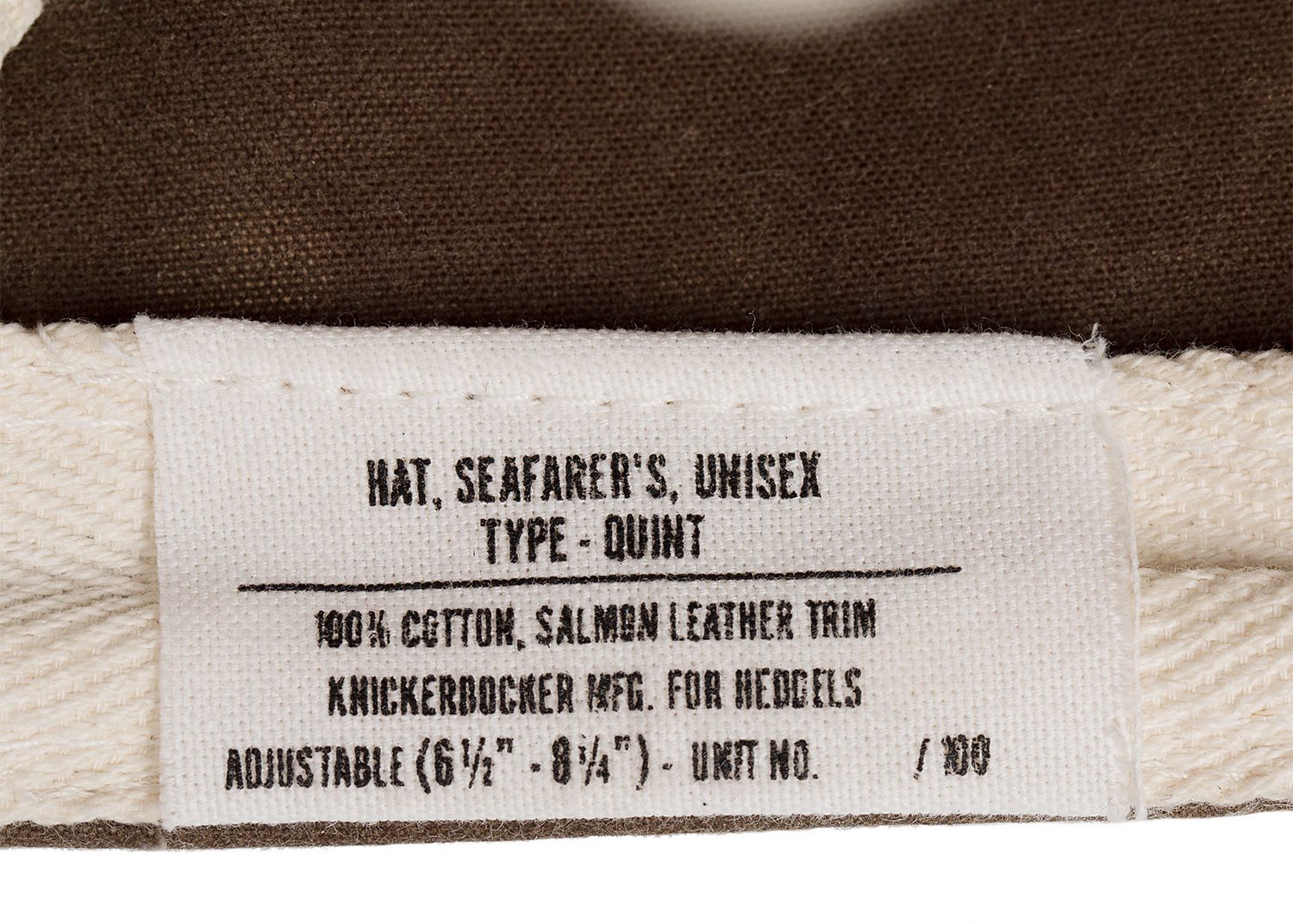

Labeling

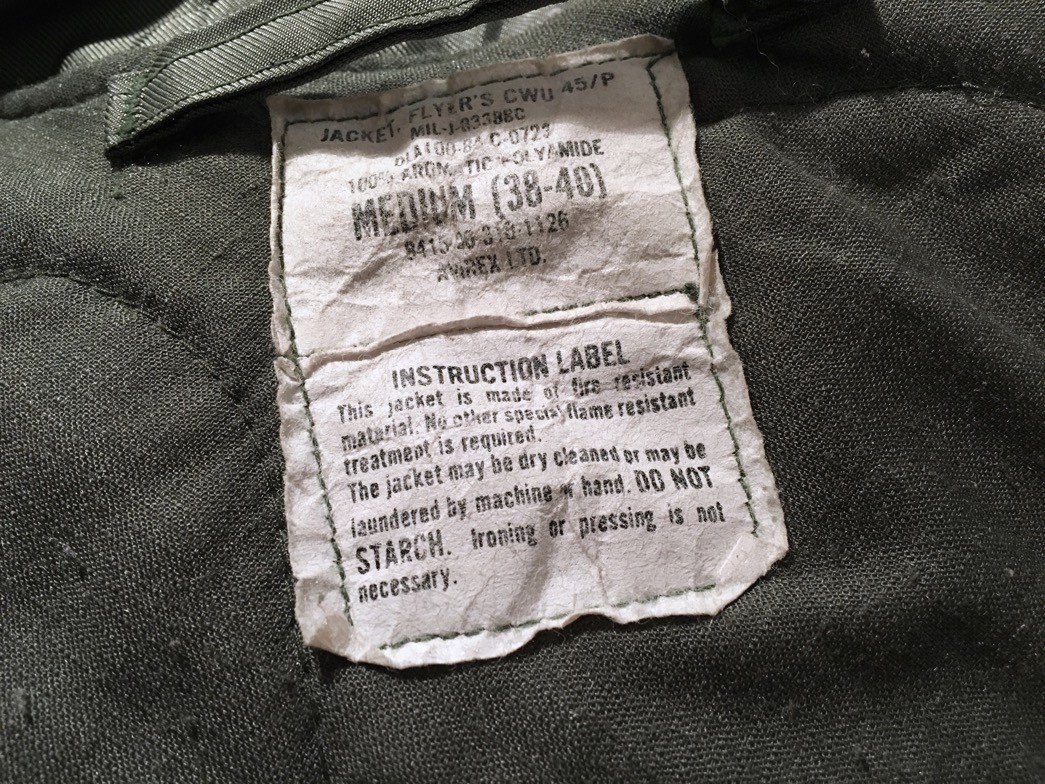

Knickerbocker typically uses a needle-woven label on their caps that hearkens back to the sportswear labels of the 40s and 50s. For this hat, though, I thought something along the lines of military labels from the 70s was more in order.

I have a vintage CWU 45/P Air Force jacket that has just the most minimally designed but maximally descriptive label imaginable.

I had them printed up at a local shop in Williamsburg, Pete’s Print Shop, onto a muslin fabric sheet. We then cut those up into the individual labels that are sewn into the sweatband of each hat. We left the edges raw on the label, they fray up nicely after some wear without any effect on the structural integrity of the hat.

Production

When our salmon skins came in fresh from Iceland, we were ready to pull the trigger on production and fired off 100 hats. The way Knickerbocker makes a hat goes somewhat like this:

First, fabric is laid out in sheets and then die cut with steel dies and a hydraulic press.

Those pieces are then assembled with a single-needle sewing machine.

And then serged with sizing tape around the edge of the inside of the hat. The sizing tape ensures the hat remains roughly the same circumference in spite of stretching fabric.

At this point, all the raw edges are sealed in twill tape on this double-needle machine, which folds and sews and seals all in one step.

Then finishing trim is attached to the raw edge at the back of the hat.

Then the interior sweatband is sewn into the inside of the cap.

The strap is bar-tacked into place and the interior label is sewn into the sweatband.

Finally, the hat is finished with a steam press on a hat form and the Quint is ready to wear.

The goods!

The Party Favor

As mentioned above, we’re doing this entirely without the permission of Universal or anyone associated with the movie Jaws, and why would we? This project has absolutely nothing to with any of them! But just to be safe, we thought we should post notice.

Oftentimes when you buy a movie prop or a piece of art, it comes with a “Certificate of Authenticity” that confirms what you own is actually what you saw on screen. Well, none of these hats were seen on any screen aside from your computer’s, so we created a hundred “Certificates of Inauthenticity” instead.

That ain’t no autopen. AJ and I spent an afternoon signing, stamping, and sealing each of these certificates by hand.

A Day in Montauk

Of course, this story wouldn’t be complete if we didn’t test the hat in its natural environment. Eric Kvatek (famed lookbook photographer for Kapital, Prps, and 45rpm, amongst many other brands) and I took a day trip to Montauk, the small fishing town at the very end of the South Fork of Long Island.

One of the few, and very backlit, photos I was able to snag of Eric.

Montauk is the self-declared sport fishing capital of the world and coincidentally, was also the home of Frank Mundus, the champion sport fisherman who inspired the Quint character in Jaws.

I visited the barber for a straight razor shave the morning of, and the results on my face are somewhere between 70s cab driver and 80s gambling fiend. Eric is an incredible talent with a camera and was able to make the hat shine on a very much non-model like myself.

This is just a small selection from the full album. Look forward to that soon!

The Rules

As with all CO-OPs, we are bound by a particular set of rules. Here’s how we fulfilled them:

1. All source materials must be minimally processed, raw, and undistressed.

The waxed cotton is raw and unworn, the salmon leather is veg-tanned and minimally processed.

2. The source and contents of all materials and hardware must be made explicit.

The fabric is an 8.25oz. Martexin waxed canvas Shelter Tent woven and sold by Fairfield Textile in New Jersey. The leather is vegetable tanned salmon skin from Atlantic Leather in northern Iceland. The twill tape on the sweatband and the inside finished edges is a natural cotton herringbone from Twill Tape. The thread is a brown poly-cotton from Efrid. The brass slider buckle is from an American distributor. The labels are printed on a domestically sourced muslin fabric and printed in Brooklyn.

3. Design, sourcing, and production decisions must be made to produce the best possible product. Cost considerations must be secondary.

In terms of look, feel, and finish, no expenses were spared to create the most accurate representation of the Quint hat.

4. Products must be wholly original to collaborating brands in design, name, and material.

The Quint hat silhouette is a modification of Knickerbocker’s standard four-panel hat design with the addition of a fifth panel and a different closure system on the back of the hat. Salmon leather was also a first for KMFG.

5. Products must represent the joint decisions of Heddels and the collaborating brand. The process will be a true collaboration, not a private label or made to order good.

J.J., Brian, and AJ all provided valuable input in the ultimate product.

6. Products must be limited, numbered, one-time-only releases. Collaborating brands may continue to use a CO-OP developed design but never the exact makeup as the CO-OP product.

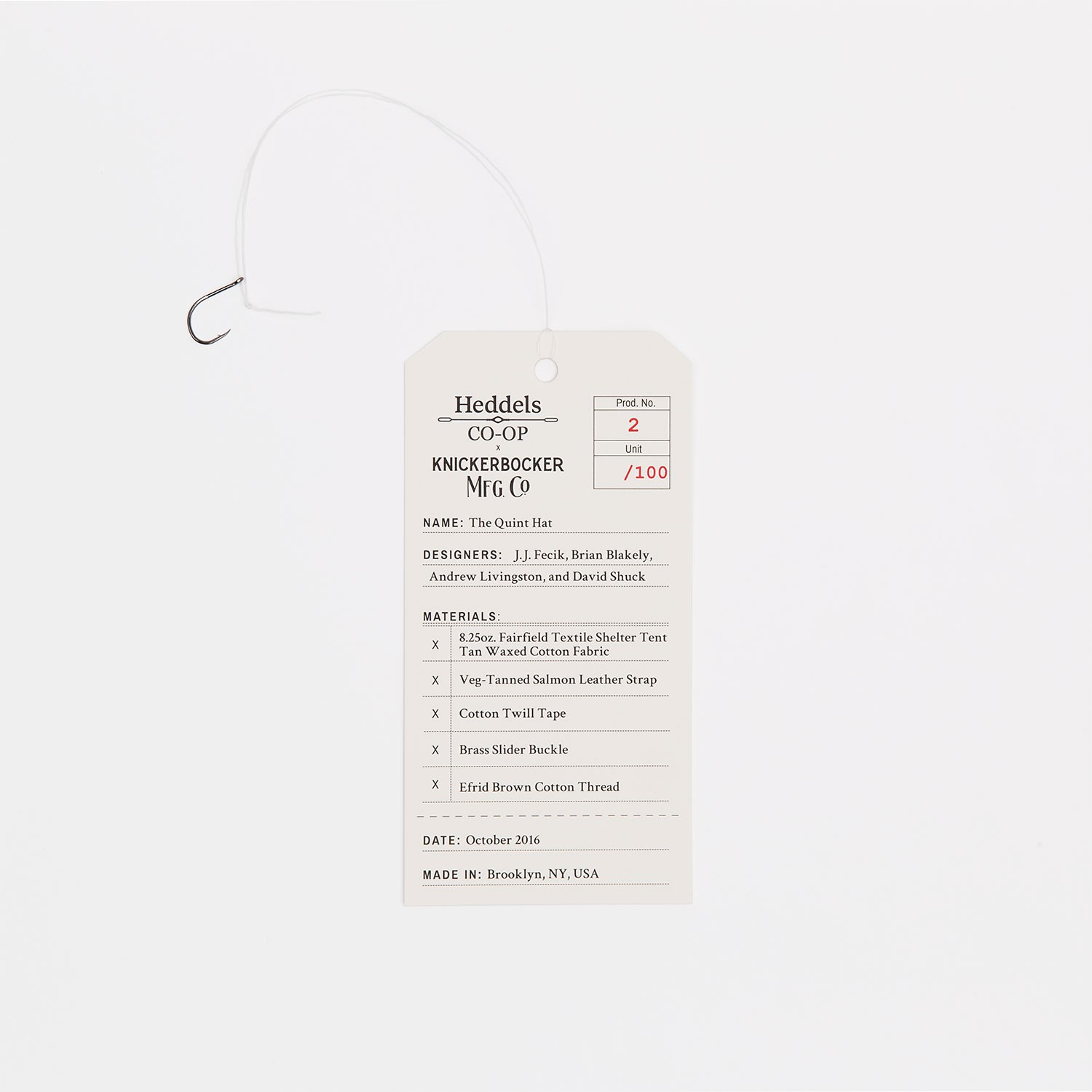

All hats are numbered on the unit, on the certificate, and on the accompanying tag. There will not be any more made.

7. No more than 500 and no less than 5 units of a CO-OP product will be produced.

100 hats were made.

8. Heddels must physically visit and document where the product is made and the people who make it.

All the photos of the factory and the process you see above were taken by yours truly. It’s a beautiful old facility and I highly recommend a visit the next time you find yourself in Bushwick.

9. Every individual involved in the creation of the product must be credited by name.

The people involved in the creation of the hat were myself, Nick Coe, J.J. Fecik, Brian Blakely, Andrew Livingston, and Eliana Hamer. Studio photography by Jessup Deane, non-model photography by Eric Kvatek. Packaging and fulfillment assistance included Allison Weiner, Ana Shioshita, Laura Anderson, Seth Pollack, and Dan Friedman.

10. Products cannot be sold until the product is on hand and paid for by Heddels. No crowd-funding, no pre-sales, no net 30.

They’re all paid for and in boxes ready to ship.

11. A product’s retail price must not exceed twice the unit cost of the creation of the product.

The hats will retail for $81 each, and we spent more than half that on production, materials, and prep.

12. Products must be accompanied by an article documenting its design, sourcing, and production.

You’re reading it.

13. Products must be accompanied by a relevant souvenir, aka the “party favor”.

For this project, that would be our Certificate of Inauthenticity and a special secret item.

14. All sales are final except in the event of a manufacturing defect.

We still mean it!

15. Products must be sold by Heddels.

The Quint Hat will be sold on our Heddels Shop. You can view its page here.

Cast Off Date

The Quint Hat will be available for purchase this Monday, November 7th at 10am EST in the Heddels Shop. Happy hunting!

All images from Jaws courtesy of Universal Pictures, who, let me reiterate, we totally have nothing to do with.