White Oak Economy is a monthly column by denim journalist veteran, Amy Leverton where she examines the interplay between the worlds of high end artisanal denim and the mall brands behind them.

Last year I saw a mug with the phrase ‘Italians do it better’ on it and of course it made me giggle. I have yet to have ‘relations’ with an Italian man and I think I can speak more from experience when it comes to their denim so lets keep it indigo today, shall we?

I recently spent a week in bellisimo Italiano, exploring a few towns and cities, marvelling at the incredible rail system and touring two of the country’s oldest and most prestigious denim mills. I haven’t spent a lot of time in Italy, despite living just a two hour flight away for most of my life and although I do feel a bit guilty about that but I also think its for good reason, because if we’re honest with ourselves, the current Italian denim scene is not buzzing like it once was.

Cast your minds back to the 80s and 90s (if you’re old enough) and you’ll remember a time when Italian denim was everything. Led by brands such as Diesel, Miss Sixty, Gas, and Reply and ruled by the godfather of denim, Adriano Goldschmied and his band of contemporaries that formed the infamous ‘Jeanious Group’, Italian denim could do no wrong. This band of denim aficionados was initially formed in the 70s and drove denim innovation through almost two decades. The hype revolved around two important factors: denim laundry and stretch fabrics, both honed and pioneered in Italy around this period. Italy was where it was at for sexy, tight-fitting, laundered, trend-led denim.

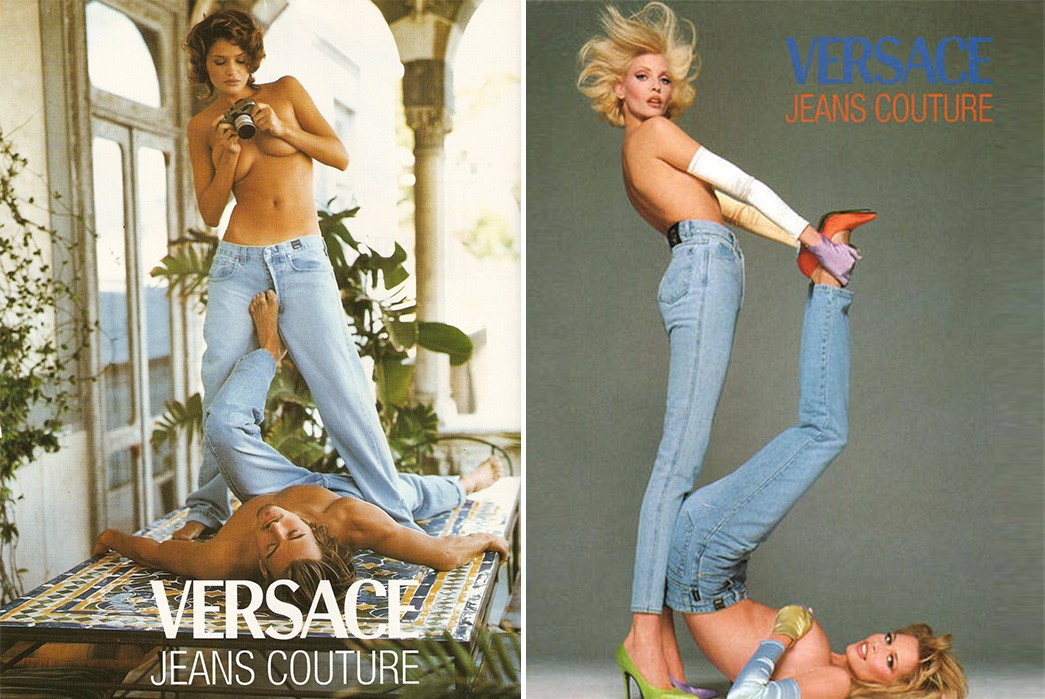

Versace denim ads from the early 00s.

We all know the current situation and its not rosy. Earlier this year, Martelli, one of the country’s (and indeed the world’s) leading laundry and finishing plants was forced to file for bankruptcy. Luckily, having since been bought out by Elleti Group (another finisher and manufacturer) its still going, but the fact it got so close to the end is sign enough of an industry struggling. I rooted around online for statistics on home-grown Italian brands but the information in Italy is very closed. I couldn’t find stats on any of the big players but I have a sense they have a considerably smaller turnover now than in their heyday.

So what is it about Italy right now thats making the situation so hard? There are several reasons, but starting from a trend and aesthetic point of view I can certainly say the 90s and 00s were the epitome of glamour and novelty in the denim industry. This meant provocative adverts from Diesel, a topless Nadja Auermann and Claudia Schiffer in ‘that’ Versace advert (above) and shaved pubic hairs from Gucci (below) keeping it naughty in the naughties. Are we as consumers into that now? Er…not really.

Yeah, Gucci went there.

Ostentation, excess, and showing off aren’t cool anymore. Showing off totally still exists (hell, I was doing it all week in Italy: posting my cultured life on Instagram visiting art galleries and eating great meals in beautiful locations) but showing off these days is not about glamour, its about lifestyle. Its where you eat, how often you work out, your day to day cultured experiences. Not your shaved pubic hair.

The problem is, sex is in Italy’s DNA and glamour is what they do best. The amount of ridiculously glamorous grannies I spotted in Venice was mind-blowing. But for the moment ostentation, or at least the 90s sense of ostentation is dead. Opulence is still acceptable but only when packaged up in a kitsch, vintage and ironic way, as per Alessandro Michele’s new and highly successful vision at Gucci.

Another problem is that we are very different consumers nowadays. We research our brands, we understand what we are buying and we listen to our peers and mentors rather than trust the big boys telling us what to do and where to buy. Now the consumers know very well what they consider cool and it isn’t a rhinestone encrusted back pocket. Gone are the days that a brand like Diesel could survive on hype alone. This has had a huge effect on the market on a global scale, where the original denim giants have generally shrunk and been replaced by multiple smaller start-ups. When I think of who is ‘hyped’ now in the mainstream market, names such as Nudie, AMO, 3X1, RRL, R13 and SJYP come to mind. They are all smaller, more transparent, artisanal and certainly not ‘show off’ brands.

The final factor as mentioned earlier is wash. Gone are the bold and experimental laundries of Italy’s heyday. Italians are the innovators of laundry and their artisanal approach to surface manipulation is renowned the world over. Italian washes are known as being more aggressive and extreme, an exaggerated version of true vintage that sets them apart from other countries. But that style is not as cool as it once was. Indeed to this day, Italian denim is still synonymous with washing and laundry, something that is going through another dip in popularity these days due to the increase in unwashed goods, more sophisticated and subtle processing and quiet design.

A rack of washed sample denim from Candiani.

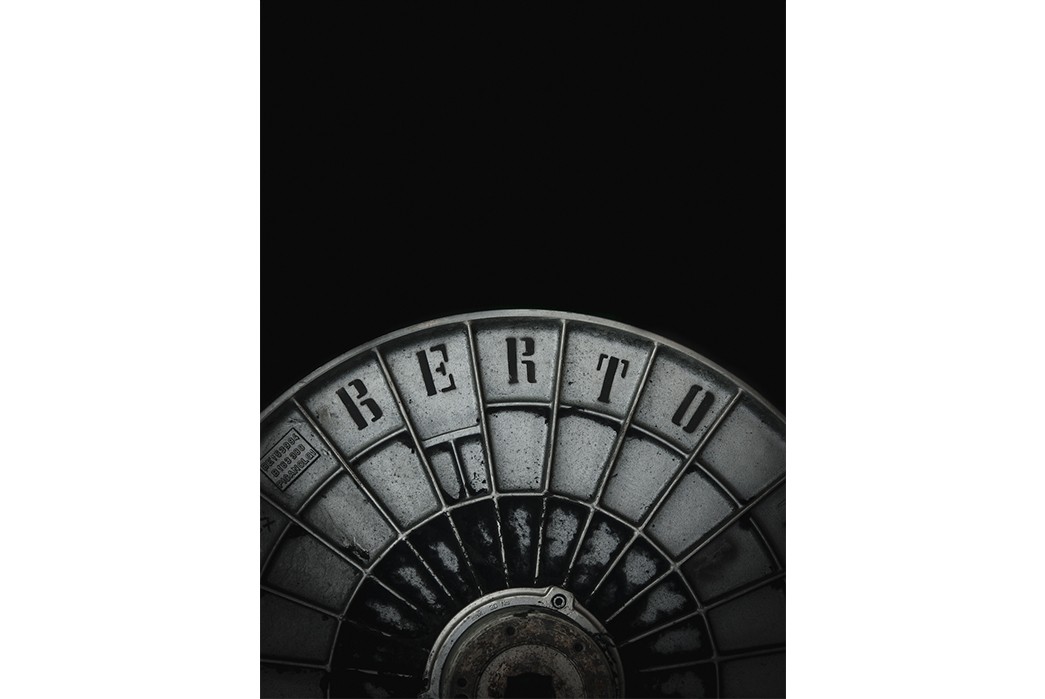

But there is still a strong and resilient base here that is succeeding despite the uncertain waters. It’s no surprise that the two mills I went to visit are known for their humble yet artisanal approach to denim and their unrivalled heritage. I visited two family businesses that have both been running a long time: Candiani denim, founded in 1938 and located in Robecchetto, just an hour outside Milan, and Berto Industria Textila, established in 1887 in Bovolenta, in the province of Padova, a couple of hours away. These guys are casual rivals: they get on, they hang out but of course there is a certain amount of healthy competition between them. Its actually charming and heart warming to witness the gentle teasing between the two.

Candiani is Italy’s most famous core denim mill, supplying a range of denims (over 300 to be exact) from high street brands to the premium-range market all over the world. They focus on a talent for stretch as well as more purist selvedge denims with innovation and sustainability woven into their DNA moving things forward. Berto is a different beast altogether. They are a small, artisanal producer, with a capacity of 6 million meters per year and supply more of the designer level brands such as Valentino, Prada, Chanel and Armani. They specialize in more fancy weaves and high-end, speciality denim.

Alberto Candiani of Candiani Denim.

Despite Italian denim struggling and despite numbers being a little shaky for both companies, they are continuing to make it work. Talking to Alberto Candiani, (the forth generation of the Candiani family) has been so interesting because we were able to discuss the global shift in trends and market from an Italian perspective. What has the biggest effect on Candiani’s business are the customers. He explains:

“Since I joined the company the market has been evolving year by year in a very hectic way. Fifteen years ago we were making 25 different fabrics, today we make over 300. Then we only had 40 customers, 50% of them were Italians. Today we have 220 accounts and only 6% are domestic.”

That’s a seizable shift right there and let’s not pretend; these are changes that are bound to have made business difficult. To set up a loom to weave a certain fabric takes multiple, complicated changes. The length and size of the slubs in the cotton; the quality, thickness and composition of the yarns; the tension of the looms; the dying processes; the finishing… the list goes on and all of these tiny changes to the way in which they spin, dye, weave and finish the fabric would have to be altered in order to develop a particular type of denim.

On the floor of the Candiani mill.

Going from 25 fabrics to 300 is a huge challenge in versatility and flexibility. This has undoubtably challenged Candiani’s functionality but they have embraced the changes with gusto and are currently weaving 25 million meters of denim a year.

Others have not been so lucky. The Italian denim scene has certainly shrunk over the last 15 years. Talking to Paolo Gnutti, Vice President of ITV denim, another of Italy’s leading mills, he paints a pretty dismal picture of how Italian denim has changed.

“Italy had the best laundries for developing collections, and for bulk production every single brand came to Italy. Today only a few companies have survived and they continue to make a difference in developing new products. However, big production has taken the flight to new countries where costs are more attractive, creating better sales margins for the brands.

“Important garment makers whose strength was the quality, had to give way to those manufacturers who would grant impossible prices in our territory for unsustainable costs. Year after year, excellent weaving companies closed for the same reasons. Today in the Italian textile market, there are only five companies remaining that produce denim fabrics and maybe four laundries that are able to provide real bulk productions.”

For Arianna at the Berto camp, it’s the same story:

“In this moment we are all in a black period. It’s like the brands are no longer able to set real trends, they are confused and not brave like in the past. They are very scared by the turnover issue so that they don’t launch new products. If they don’t sell, then we don’t sell and the manufacturers can’t work too. We need fresh air, and probably a new way to create and sell product.”

So basically what they’re all saying is when the whole industry starts thinking with their pockets and not their creativity, things go downhill fast. I think thats a fair analysis of how fast fashion has impacted the global market, not just Italy, right? Italians have a fantastic way of explaining things and I love how Paolo puts it: “The emotion is replaced by the costs…”

Bang-on Paolo, Bang. On.

Despite the fact that Italy is full of the artisans that fast fashion usually eschews, it’s interesting to hear that Candiani does some work with Zara and Topshop very successfully. I know a lot of the readers here would look down on such brands but I have to say, working in trend I fully appreciate what they do and how they have set themselves apart from the rest. Because to me, both companies are still very creative. They don’t just knock other people’s designs off, they produce inspired and original ideas and I’ve often spotted them getting trends right on the money before I see them on the runways.

They are more price conscious than say the Diesel’s of the world but of course this is aided by the fact that their operation and in turn their minimums are HUGE, making prices more manageable and higher-end fabrics obtainable to them. Candiani has managed to make it work for their business. What they produce for those retailers is not huge and is often focussed on higher end, speciality denim, but I think its a sign of their progressive character that they haven’t closed their minds to that side of the business because that business is changing the shape of the industry right now, whether we like it or not.

At this point it makes sense to compare past case-study of the last big market change: the boom of the premium LA denim scene in the 00s.

As I said earlier, Candiani are masters of stretch and much like the Jeanius group back in the 70s and 80s, they saw a future in stretch that many did not. So they were honing their stretch capabilities and innovation when the rest of us were busy wearing rigid Diesel bootcut jeans down the local disco. Because they had something different to offer, by the late 90s, stretch fabrics became more than 50% of their production. “Denim was changing its face too, becoming more sophisticated in its ring effect, looking authentic, but comfortable and sexy.” Alberto tells me over an espresso in his hometown.

“At that point some of these customers told us our fabrics were too expensive and they were looking for alternatives, and they tried to push us to make investment abroad, in developing countries. But we always refused because we are too loyal to our territory. Our reaction was to make even more beautiful and sophisticated fabrics, with new stretch technologies. We had the perfect product, in the perfect place and at the perfect moment.”

And we all know what happened next:

“7 For All Mankind, Lucky Brand and Paige Denim were three of our initial customers and they became huge very fast. They were simply making a better pair of jeans (especially for women’s) with no crazy washes, at least in the beginning, they created a new kind of branding and marketing, almost a new Californian lifestyle and their customer was willing to pay up to 300 USD. Many others followed and a lot of them are still very good customers of ours. LA represents 30% of our sales, the US 38% in total.”

So holding steadfast to your principles, whilst driving ahead with innovation seems to be the key to Candiani’s success. But Italy hasn’t made it easy on these home-grown companies. When the industry started collapsing it seems pretty clear the government did little to help the situation. “Our Italian taste is incomparable,” Says Arianna from Berto, “But from a price point of view we are obstructed by Italian laws. We have very high taxes (all the investments and turnover is taxed) making production in Italy very expensive.”

Arianna Morimando (center) of Berto Mills.

Alberto also talks on the same subject :

“Since the 80s the Italian government did nothing to preserve the textile and manufacturing industry, nothing to keep it domestic. The country did not understand the importance of such a big chunk of its own textile and fashion manufacturing. I had a conversation with a vice prime minister once, I told him what we do at Candiani and after 20 minutes of conversations he goes, ‘So you guys trade fabrics from China?’ Clearly he did not understand one word of what I was saying. He couldn’t believe that in Italy we were still making denim fabrics”

And again this comes down to the preconception of luxury and what it means today. When you think of ‘Made in Italy’ I’m sure most people think about leather handbags, cashmere, tailoring and the big, Italian fashion houses such as Fendi, Prada, and Gucci. A jean is is rarely a luxury item, unless its coming from of said fashion houses and totally covered in embellishment or hand-work.

Many people are prepared to drop big bucks on runway, but denim? The consumer is savvy and you can’t just produce something for $20 and charge $300 for the brand name name any more. I visited Manuel Canova, an Italian denim expert and owner of Manufactus (a home-grown premium men’s denim brand located near Berto) to talk about his outlook and the changes he’s seen to his industry. He cites the shallowness and hype of the 90s as the beginning of the end for some of these big brands:

“After the 90s, it all changed into marketing and advertising. Most Italian denim brands are not focussed on next level product but more on cool advertising campaigns. I’m not saying thats necessarily negative but I do think they have lost touch with the consumers who are real denim lovers. Italian denim was killed by selling systems that do not put a focus on the customer, you can’t invent a fake history about quality. The credibility has been lost and to rebuild a brand after that trust is gone is so difficult.”

Manuel works on a small, artisanal brand of the type we’ve been seeing cropping up globally over the last decade, where premium means craftsmanship, not hype. His business is transparent, it’s small, it uses only the finest raw materials, machinery and expertise.

Manuel Canova of Manufactus. Image via Mauro Fardin.

To me, that is luxury: pride, transparency, passion, knowledge; these are now luxuries in today’s market. At the end of the day, consumers today are way more savvy than some brands give them credit for. They can smell horse s**t a mile off and are starting to only respond to genuine passion, genuine brands and a genuine story. As Paolo from ITV tells me:

“Now the free space belongs to the emerging “non-brands” because they do not look towards the costs, but they are focused on the product, on what they like and they look for a product that is able to transmit an emotion, an identity.”

Noise, hype and celebrity are not luxury any more, and for those customers who can’t afford luxury, well they now opt for fast fashion. Like it or not, that is the polarisation of the industry right now. The middle market as we once knew it is dying and Italy is caught right in the middle of it. We still don’t know how its going to resolve itself but we can only move forward from this moment, never backwards. As Manuel rightly says, “The success of Italian denim in the past is not replicable today. Brands are connected to mass market and creativity is lost. They have changed the look of their product that no longer reflects their DNA. The old glory days are history.”

So how will Italian denim continue to survive? Alberto thinks it’s simple, “The last guys standing are those that stood against the system, surviving the markets thanks to creativity, innovation and a different sustainable approach to industrialisation and product engineering.”

Then he shares a fact with me that really sums up the possible future of social sustainability when it comes to manufacturing: “I always proudly say our workers at Candiani represent the 0.1% of the global textile workforce which can finally afford to buy the product that they are making. This is also part of sustainability on a larger economical and social scale.”

Pattern laying at Manufactus. Image via Mauro Fardin.

This point kept coming back to me again and again as I wrote this article and when I think about the future of domestic manufactoring be it in Italy, the USA or even England. How can Italy move forward, remain relevant and successful in a world that has almost completely changed around them? It’s one thing to be an artisan, to tell a story, and to honor your heritage but without being able to sustain yourself and your workers, you are over. This Italian mill has managed to ride every wave of change since the 40s so I think they are smart enough to do it again and also smart enough to take notes from.

So, back to the title of the article: Do Italians really do it better?? Well, if we compare denim to life, despite still having no firsthand experience I would say ‘it depends on the guy’. Not everyone will survive this really unique time in retail, manufacturing and industry but the very best dudes always do well, no matter where they come from.