The raffle has now ended. Winners eligible to purchase will be notified by 11:59PM ET Monday, February 12.

This is the third iteration of our CO-OP series, our collaborations with brands we admire to create limited runs of specialized products exclusively for Heddels readers. By working with the brand, we hope to dive far deeper into who they are and how they operate than we ever could have with a profile. We have an extensive list of rules that we have to abide by for each product to bear the CO-OP label.

Our CO-OP articles serve as the complete documentation of how we created our product, from concept to sales. This article covers the creation process with athletic shoe brand PF Flyers and our third collaboration project, the Mercury All-American.

I’ve been a lifelong NASA and space fan. When I was in the fourth grade, a friend and I won a NASA journalism contest commemorating the 30th anniversary of the lunar landing. Aerospace engineers visited our elementary school and we got to attend Space Camp in Florida as a prize.

My fascination with space stems from one of my core beliefs; what makes people better is more people. Alone, we are weak, afraid, and incapable, but together with pooled resources and specialization, there’s little we can’t accomplish. I’m currently in a heated office, sitting in an ergonomically designed chair, typing on a computer, connected wirelessly to the internet. Each of these things required the work of millions of people for me to enjoy. And I think this idea is represented perfectly by the early days of space exploration.

It took focused manpower, innovation, and effort on a scale humankind had never seen before to send one vulnerable soul into orbit. The void of space is the most inhospitable environment imaginable. There’s no air, no ground, no food to eat, water to drink, or even gravity to keep oneself oriented. And yet, with enough people on the problem, we’ve had humans live for years in this desolate vacuum for years on end.

It is the ultimate challenge, “the final frontier”. And in the 1950s, the United States and the Soviet Union set out to conquer it.

Why PF?

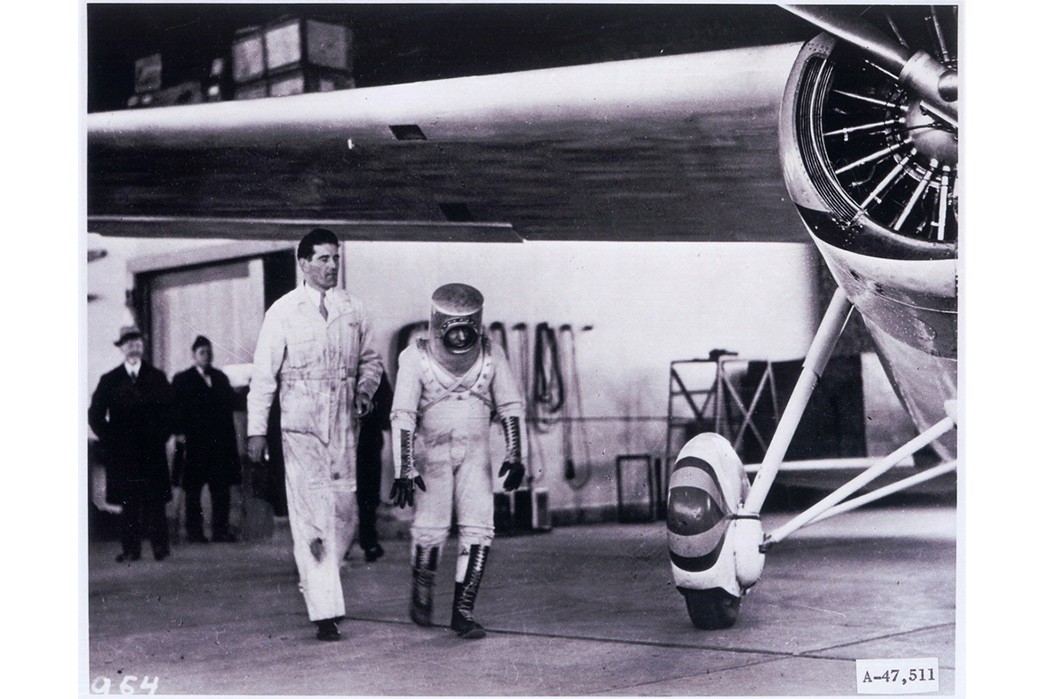

Pilot Wiley Post in BF’s pressure suit in 1935. Image via Pioneers of Flight.

Tens of thousands of people and hundreds of companies were involved in the gargantuan effort to put an American into space. PF Flyers and its original parent company B.F. Goodrich were two such businesses. You may recognize B.F. Goodrich as a tire brand but in the 1950s, B.F. was a massive conglomerate diversified across a variety of other fields including athletic shoes, business consulting, and aerospace technology.

One of the necessities for high-altitude travel was a pressurized suit or cockpit to provide oxygen to the pilots. In 1934, BF was the first company to build a practical pressurized suit for pilots, which took its wearer to a record altitude of 50,000 feet. This design would become the basis for all future pressure suits.

B.F. Goodrich continued to develop suits for the American military through the 1950s. The model of choice for test pilots was the Navy Mark IV. With a few slight modifications, the Mk IV custom built by B.F. became the suit used by all of the seven astronauts of the United States’s first manned space missions, the Mercury Space Program (1958-1963).

The original Mercury 7 astronauts in their modified Navy Mk IV BF Goodrich spacesuits. Image via NASA.

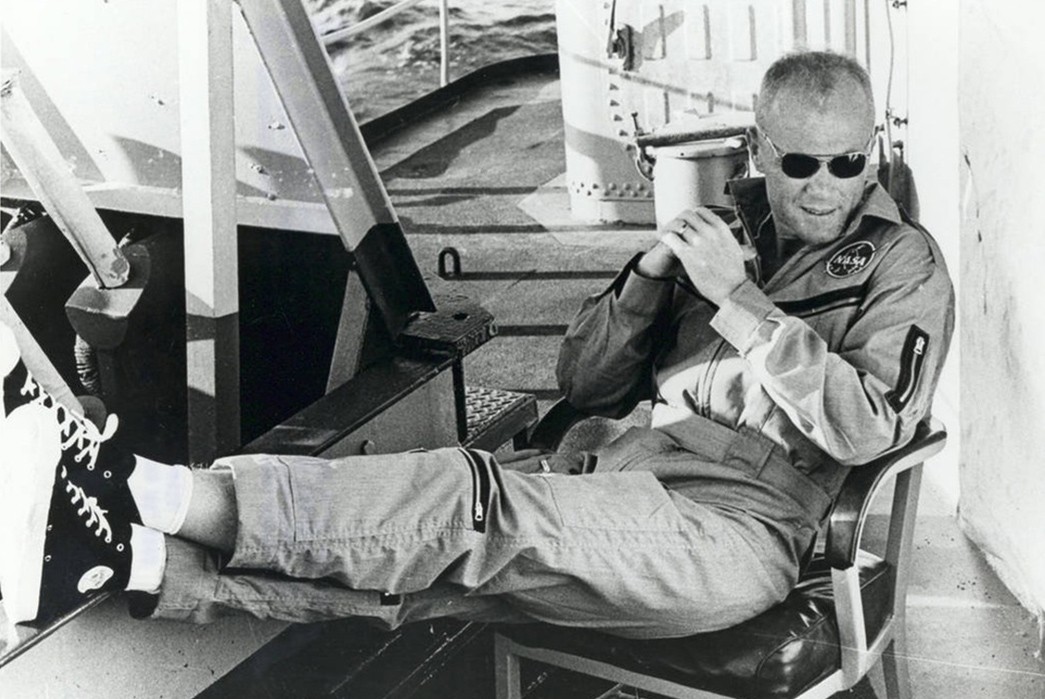

BF was more involved, however, than just producing the suits. During the astronauts’ extensive ground training for physical fitness, wilderness survival, and simulation training, many of them wore sneakers. These were likely a standard issue military athletic shoe, as used in pretty much all branches of the American armed forces in the 1950s and 60s, and BF’s footwear brand, PF Flyers, was one of the companies with a contract to make them.

Now, we can’t guarantee that the shoes the astronauts wore were made by PF, but the odds are pretty good.

While the astronauts wore BF suits in the air, they had on PF Flyers on the ground, helping them truly run faster and jump higher than anyone in history.

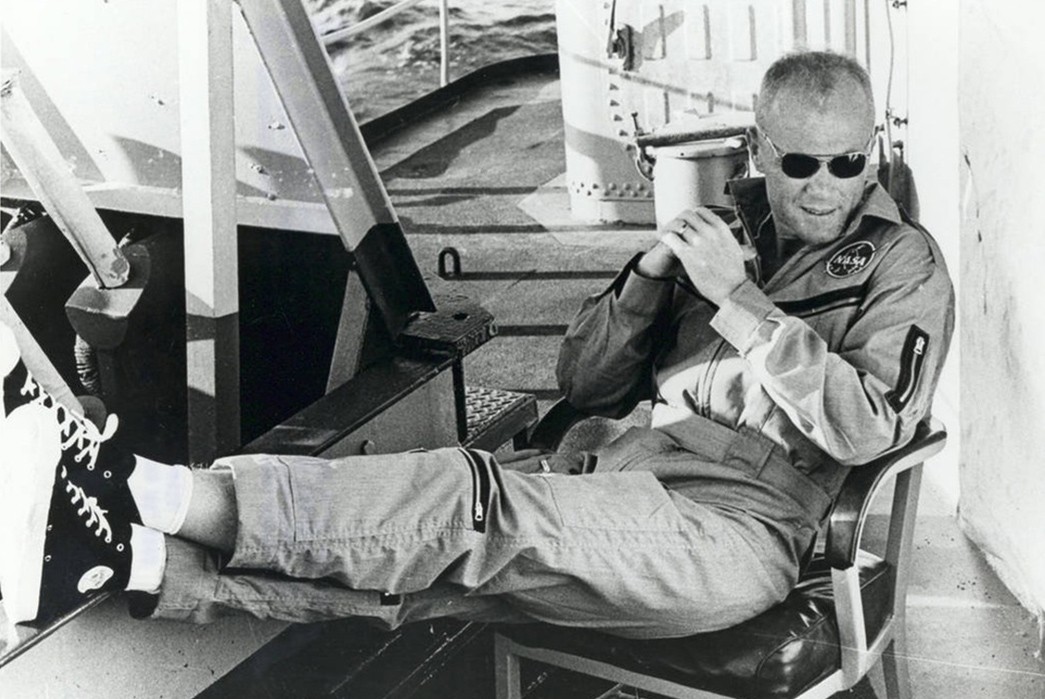

Mercury astronaut John Glenn. Image via NASA.

PF Flyers has experienced a revival in recent years, as they’ve brought back American production and many of their early designs with the support of a new parent company, New Balance. And I first heard the above story from Alyasha Owerka-Moore, their brand historian and a footwear and design veteran.

Despite their large corporate backing, PF is an intimate team of about a half dozen. They can use the resources of New Balance while still working on small passion projects. I’d been in touch with PF since late 2014, when they announced their new Made in USA program. Since then, they’ve released collaborations with Tanner Goods, Gitman Vintage, Sterlingwear, Brooklyn Circus, and many more heritage oriented brands. They seemed like an ideal partner with an amazing story to tell.

I first pitched the idea of doing a Mercury shoe in early 2016, but their production calendar was booked until Q1 2018 (hey, look at the date!). The timeframe for companies with global production is massive. It went on the back burner until that summer, when I met Christopher Tobias and Patrick Trubiano, PF’s Global Merchandising Manager and Product Line Manager, respectively, while we were covering their collab with Gitman. We got to talking about the Mercury story and swapped a few of the photos above and the project was underway the next week.

The All American Model

A Bob Cousy All American from the late 1950s.

Every shoe is built on a “platform”. While our past projects have been relatively simple in design (a zip bag and a hat), shoes require significantly more engineering. PF had recently developed their All American, a shoe based on the one worn by Celtics basketball star Bob Cousy in the 50s and 60s. The All American happened to line up perfectly with the time frame of the Mercury astronauts, and if you look closely at training photos, a few of them appear to be wearing a very similar shoe.

The present day All American. Image via PF Flyers.

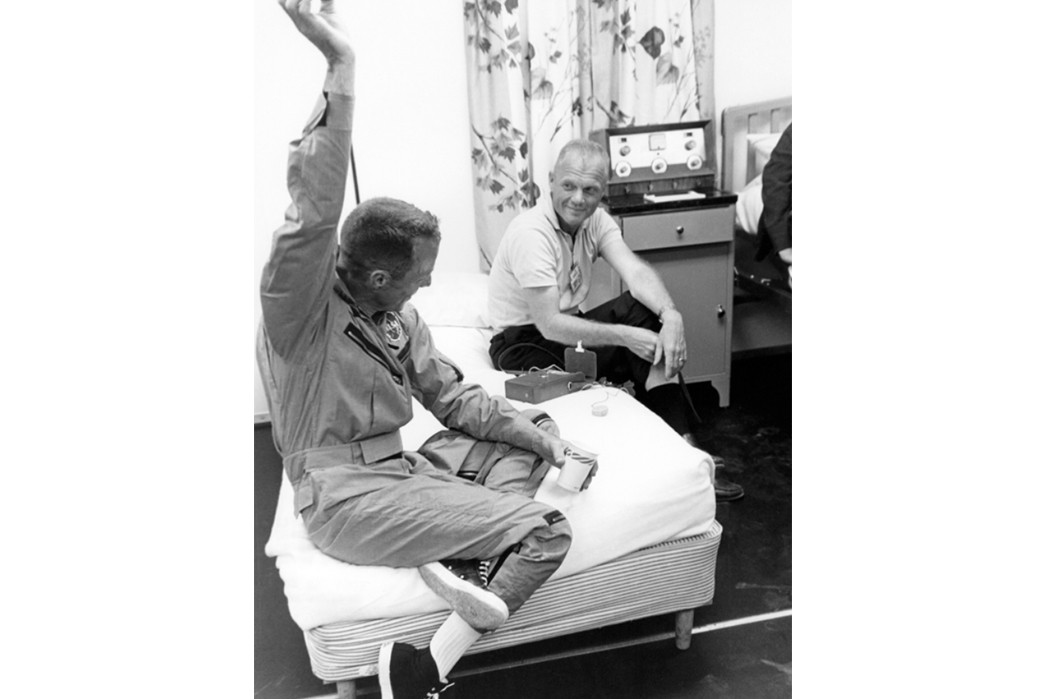

Scott Carpenter and John Glenn before the launch of Mercury-Atlas 7. Image via NASA.

I asked PF’s production manager, Robert O’Donnell, what liberties we could take with materials and design details and he told me, “Whatever,” but quickly added, “within reason.” Like the pioneers in Project Mercury, those were boundaries I was prepared to test. We had our framework, now to figure out how to dress it.

The Inspiration

Scott Carpenter’s boots from his Mercury suit. Image via Smithsonian.

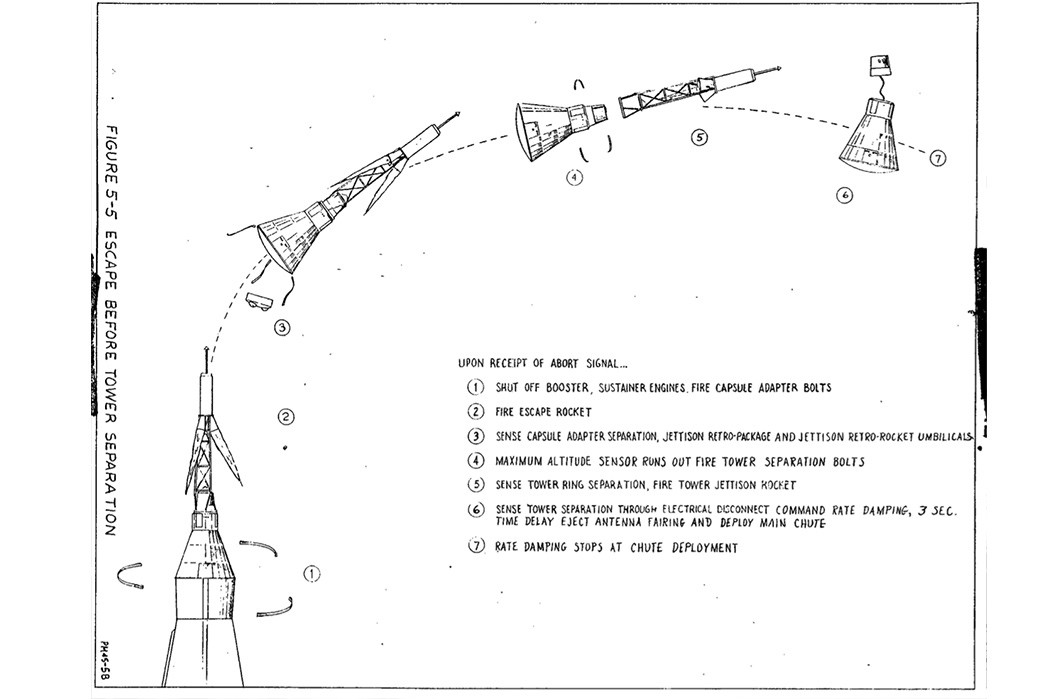

The concept was to make a shoe that was a microcosm of Project Mercury itself, incorporating as many materials and designs from the original program as possible. Mercury was NASA’s first attempt at putting a person into space, so everything they created was wholly original. It was also the late 1950s, where the boom of industrial technology development in World War II continued to advance at a breakneck pace. As a result, many of the artifacts from Mercury are crude customizations made from totally new materials.

“Space age” often evokes images of sleek minimalistic designs, Mercury, however, was anything but that. The suits themselves have an enormous amount of handwork and “aftermarket” customization (think more Star Wars than Star Trek). As astronauts and scientists discovered problems with their designs, they often built over them, rather than start from scratch.

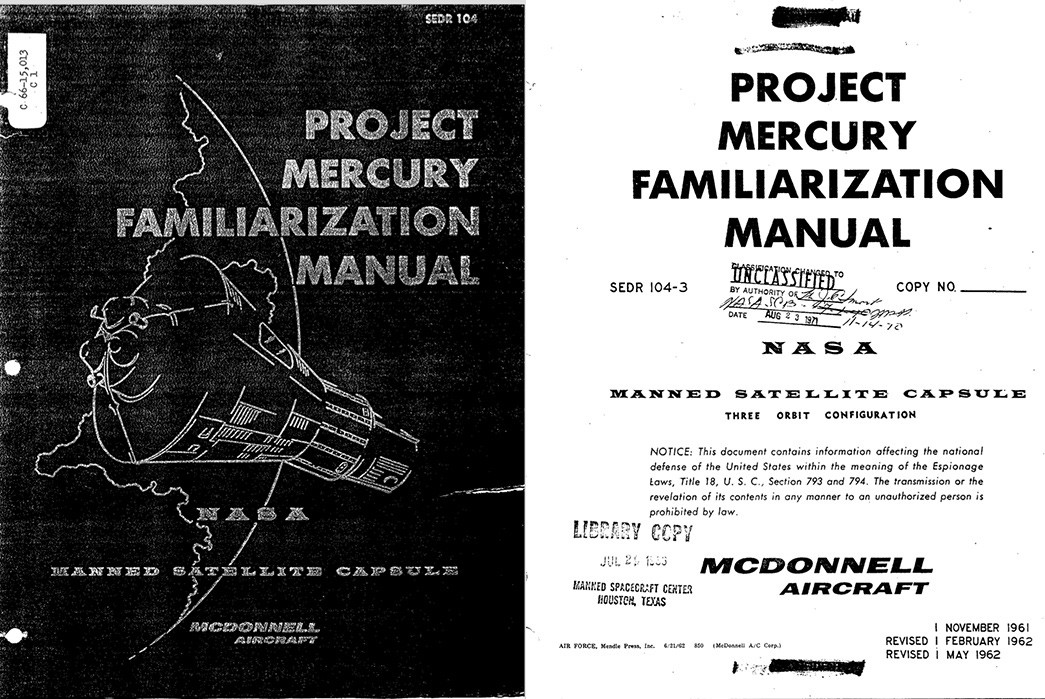

Much of this information, however, was classified state secrets. The Space Race was a key component of the Cold War with the Soviet Union and the specific materials and designs were long kept under lock and key. Not so in 2018! Thanks to the Freedom of Information Act, you can just download thousands of pages of Mercury Era NASA documentation, detailing materials, design specs, and even the suppliers they bought them from.

I spent hours poring over diagrams, manifests, and descriptions of how to put a man into space 60 years ago. Within these texts, I found the specifics that would make up our shoe.

The Materials

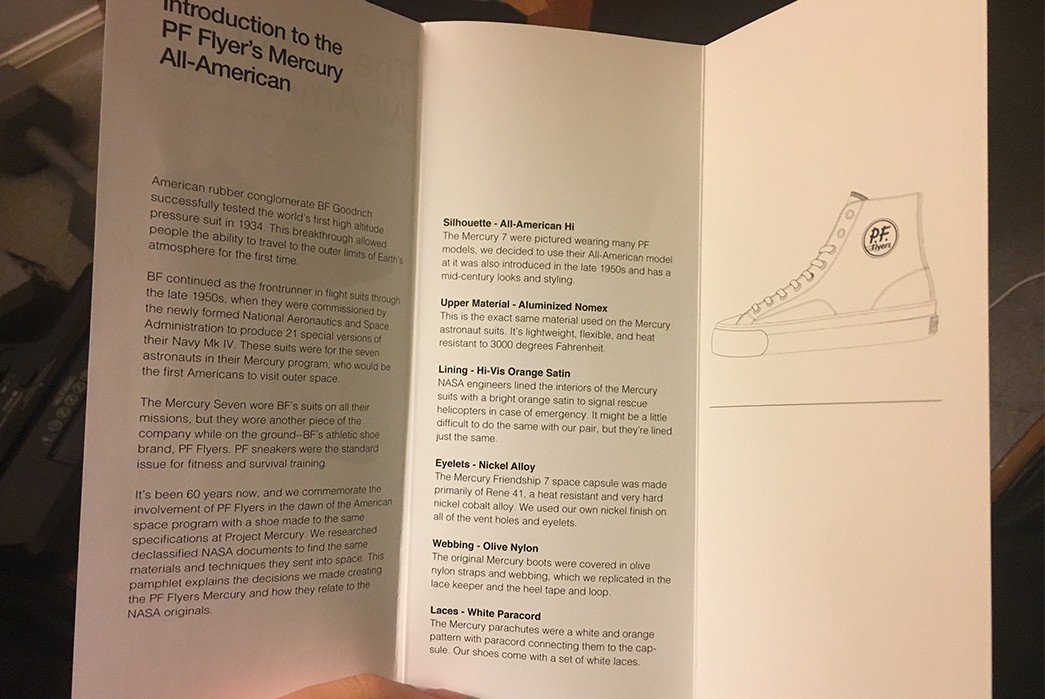

The components of the shoe spread across the entirety of the gear used in the Mercury project.

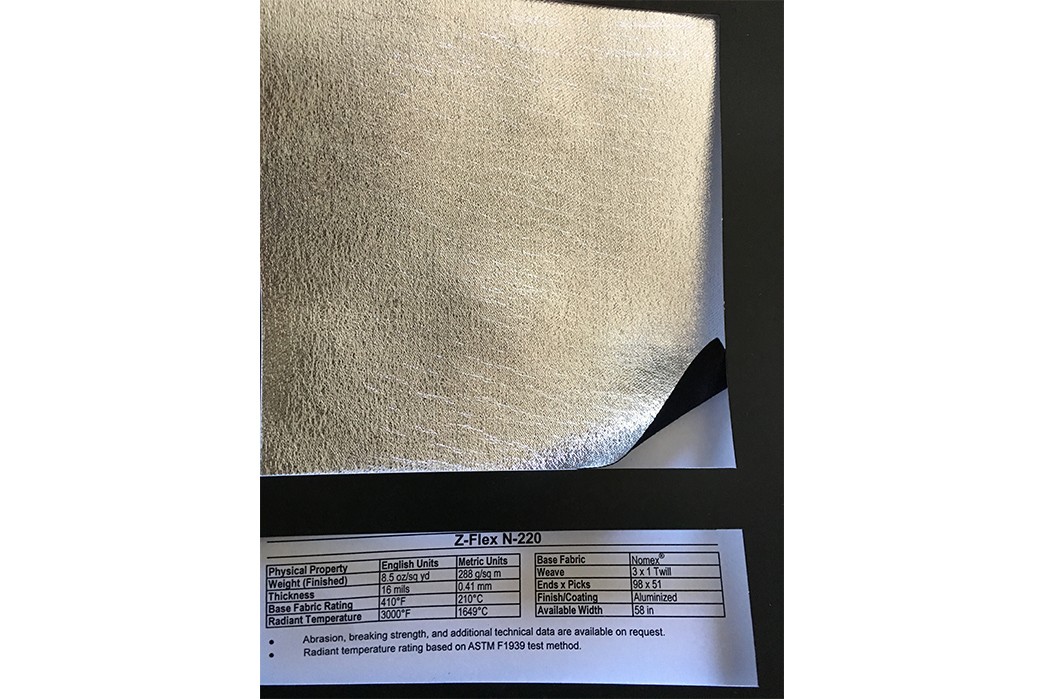

Upper – Aluminized Nomex

I felt the key to this whole thing was giving the shoes the look and feel of a piece of the spacesuit. The suit itself was made of a heat resistant aluminized nylon. The most heat resistant nylon material available at the time was Nomex, an aramid developed in the early 1960s.

The “aluminumization” of the material makes it like a flexible mirror, reflecting heat off of it rather than absorbing.

Gum Rubber Outsole

The Mercury boots used a rubber outsole, resembling halfway between a Bean Boot and a fireman’s boot. Luckily, this type of material is PF Flyers’s bread and butter.

Orange Satin Lining

NASA engineers lined the interiors of the Mercury suits with a bright orange satin to signal rescue helicopters in case of emergency. It might be a little difficult to do the same with our pair, but they’re lined just the same.

Nickel Alloy Eyelets

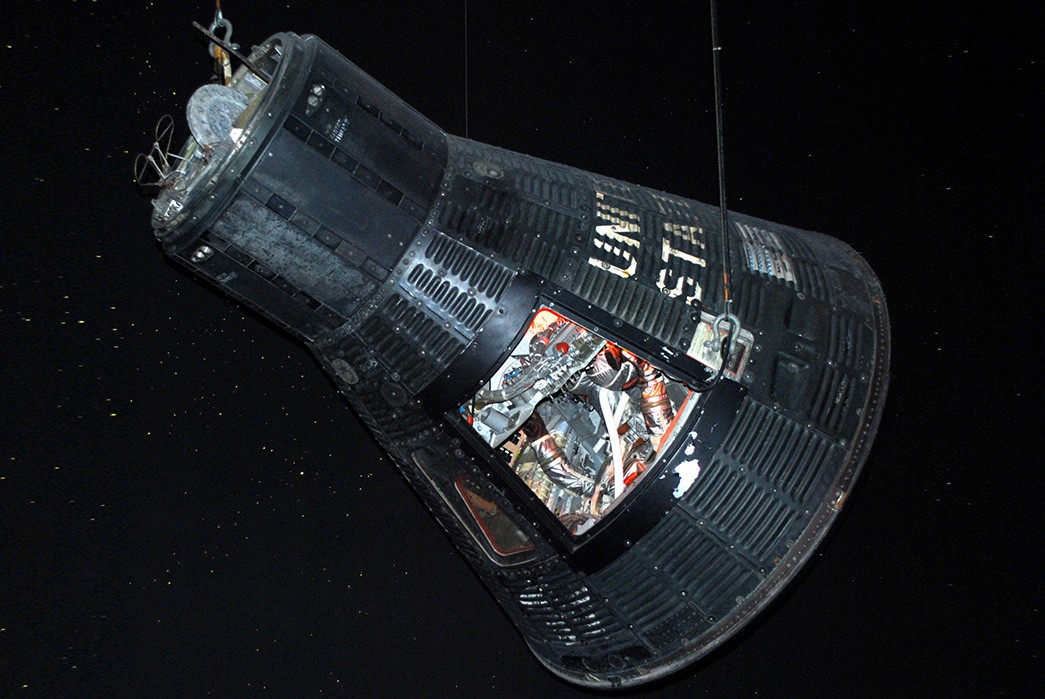

The Mercury Friendship 7 space capsule was made primarily of Rene 41, a heat resistant and very hard nickel alloy. We used our own nickel finish on all of the vent holes and eyelets.

Olive Nylon Webbing

Close up of the Mercury space suit. Image via NASA.

The original Mercury boots were covered in olive nylon straps and webbing, which we replicated in the heel tape and loop.

White Paracord Laces

Mercury 9 Landing.

The Mercury parachutes were a white and orange pattern with paracord connecting them to the capsule. Our shoes come with a set of white laces.

Embroidered Patch

Finally, we wanted a PF Flyers ankle patch reminiscent of the original “meatball” NASA logo.

Sourcing

All of these ideas combined to create a concept shoe that looked like the above picture I dummied up in Photoshop. Actually bringing it to life would be another challenge altogether.

I knew the tallest order would be finding the aluminized nomex so I set to it first. Surprisingly, it’s still made at an industrial scale for people working in extreme heat (think steel mills and welders). A few searches away, I found Newtex, a high temperature textiles and engineering company. And a phone call later, I had a spread of all of their flavors of aluminized nomex in front of me.

The real looker was the one on the right, Z-Flex N-220, a 3×1 twill with a heat resistance of 3000 degrees Fahrenheit. I, of course, did the first thing any reasonable person would do after receiving a package full of fireproof fabric: I turned the gas on my stove on high and giggled like an idiot as the swatch batted away the flames.

We had our upper.

As you may have noted, previous projects were very “cowboy-esque”, we just bought material and went to work. There are many more steps when working with a large company like PF/New Balance. Sample yardage of the Newtex fabric was sent to their HQ in Boston for a variety of strength and endurance tests to make sure it would cut the mustard as the upper of a shoe. I didn’t get to see this personally, but apparently they have robotic feet that take upwards of a 100,000 steps to test out their durability.

The very first sample, made up in a test material and temp patch. Image via Chris Tobias.

Once our fabric had passed the robo-marathon, the rest of the sourcing went smoothly. The rubber type and heel tape took a couple attempts, but we got it down, they nailed the eyelets and heel tape on the first try.

The second sample with the nomex material, embroidered patch, and test sole rubber.

In the midst of these samples, we also decided to add a heel pull tab attached with a box stitch and a lace keeper loop on the tongue. The motivation for the second addition was purely personal as I hate it when my sneaker tongues slide off to the side.

Otherwise, we were ready to make shoes!

Production

In conceiving this project, both PF Flyers and I had imagined a large production run of shoes. But as the details came in and we became enamored with the Nomex material, the retail cost began to rise. Materials designed to be blasted into space are generally quite expensive, even if they are 60 years old, and the material is priced on the order of shell cordovan.

We decided on a run of 21 pairs, the same number of spacesuits NASA used in the Mercury space program and sent them into production. Unfortunately this means sizes are limited (men’s US 9.5, 10, 11, and 12), but boy are they handsome.

If I have one regret for this project, it’s that this section is not longer. I was unable to view the production at PF Flyers’s facility in China. This is a CO-OP rule and one we did not fulfill this time around. We were unable to work the timing with the factory, but trust it will not happen again.

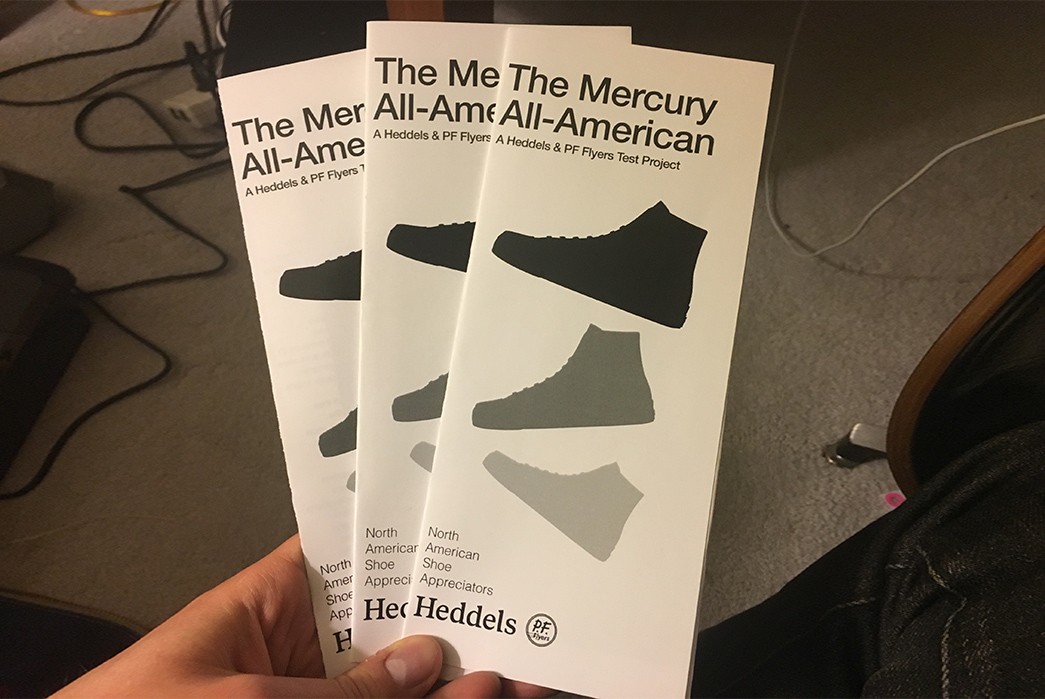

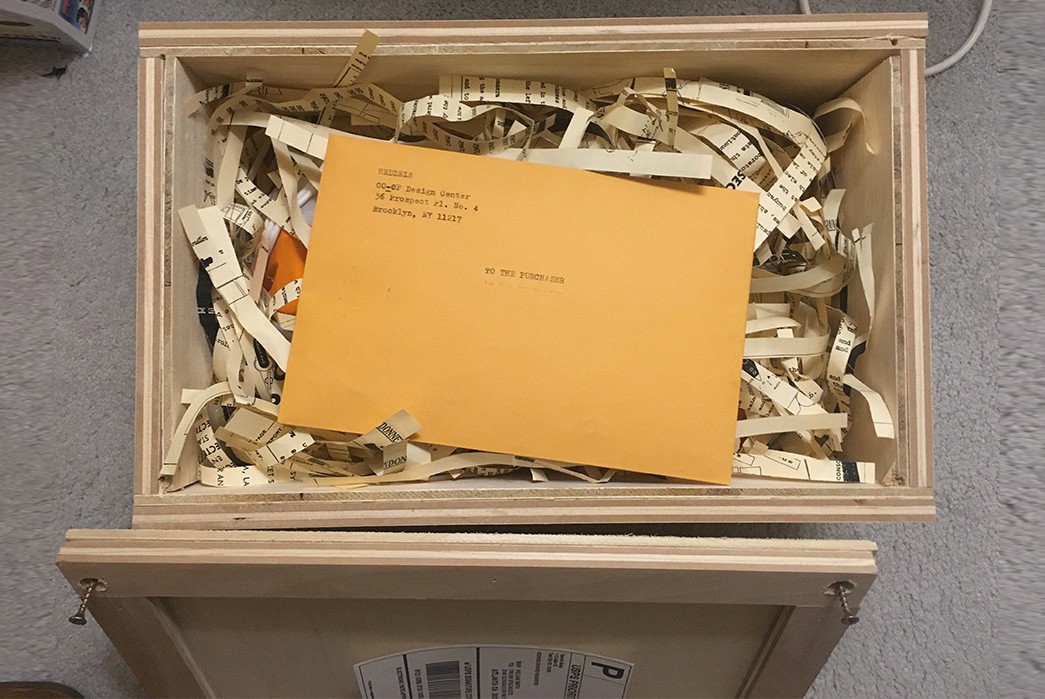

Packaging

Now that we had these space beauties on hand, we needed to make packaging that was worthy of them. Since it was such a small run, it didn’t make sense to use PF’s regular channels for boxes. And also because it was such a small run, meant we could get really wacky with it.

I recruited the help of graphic designer, artist, and fellow space fan Ross Evertson to help with the design. We considered boxes that looked like those portable air conditioners the astronauts carried with them to the launch pad, until we saw these images of wooden NASA shipping crates. And then learned you can ship wooden boxes through the mail.

That lead me to Fin Art, a custom carpentry shop in Denver, Colorado, who were more than happy to spin up 21 crates.

I still couldn’t get the image out of my head of that white and orange parachute and thought there had to be some way to include it in the mix.

I bought some parachute ripstop nylon and whipped up a test drawstring shoe bag on my home sewing machine.

Then we went back to our old friends from CO-OP 1, Winter Session, who were more than up to the task of creating 21 more for production.

Roy and Tanya also lent their laser cutter to create a stencil for branding the outside of our crates.

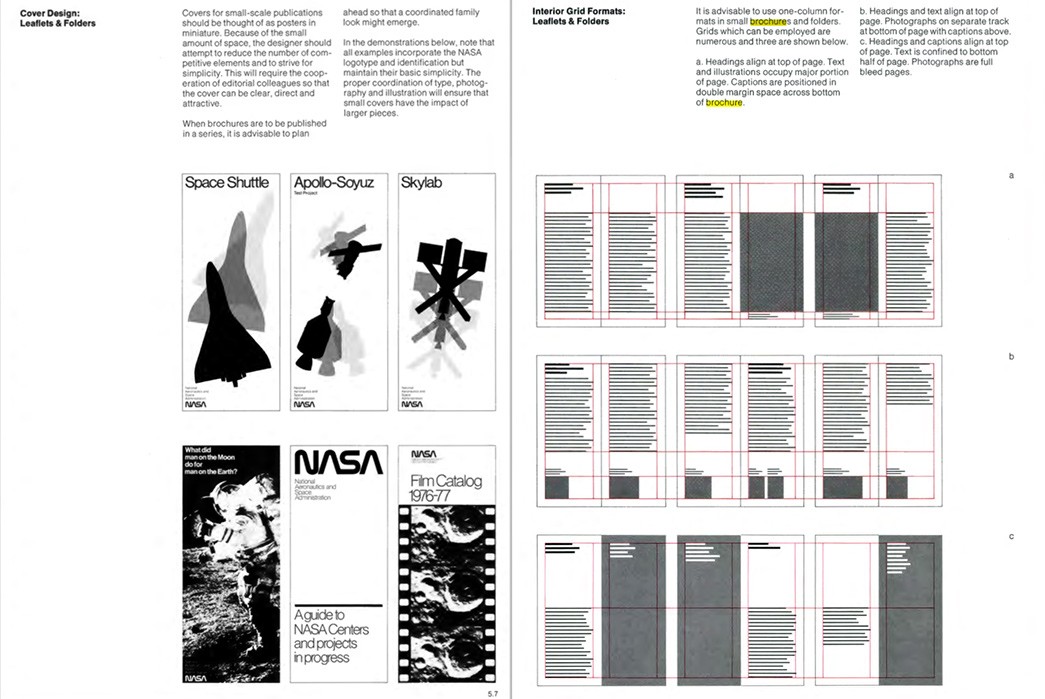

Ross and I were also obsessed with a piece of graphic design history known as the NASA Graphics Standards Manual, which was a guidebook commissioned in the 70s to standardize all of NASA’s logos, typefaces, letterheads, signage, and anything else you can think of on paper.

There’s a whole section on pamphlets and brochures, and even though it’s about ten years after the Mercury program, we still wanted to give it a go.

So we made our own brochures for the shoes.

All of this is included in a wooden crate packed with shredded declassified NASA documents from Project Mercury.

Make sure you have a screwdriver on hand though.

And finally, this wouldn’t be CO-OP unless I did a goofy photo reenactment. Here’s John Glenn after he set the record for orbital flight and me by the dumpster behind Winter Session.

CO-OP Rules

1. All source materials must be minimally processed, raw, and undistressed.

I’m not sure we could hurt the nomex if we tried.

2. The source and contents of all materials and hardware must be made explicit.

The upper material is from Newtex of New York. The components from the shoes are from PF/New Balance’s Chinese supplier.

3. Design, sourcing, and production decisions must be made to produce the best possible product. Cost considerations must be secondary.

Yeah, putting a hazardous materials fabric on a sneaker and shipping your product in a wooden crate really aren’t the most fiscally sound decisions, but we did feel it made for the most narratively interesting product.

4. Products must be wholly original to collaborating brands in design, name, and material.

Although it is on the All American platform, there are multiple modifications to the design to make it a unique silhouette. The name is new and no sneaker has ever been made of aluminized nomex before I think ever.

5. Products must represent the joint decisions of Heddels and the collaborating brand. The process will be a true collaboration, not a private label or made to order good.

Production decisions were made as a team between myself, PF Production Manager Robert O’Donnell, and Line Manager Patrick Trubiano.

6. Products must be limited, numbered, one-time-only releases. Collaborating brands may continue to use a CO-OP developed design but never the exact makeup as the CO-OP product.

Shoes are tagged, numbered, and we have no plans to make any more.

7. No more than 500 and no less than 5 units of a CO-OP product will be produced.

21 pairs were produced.

8. Heddels must physically visit and document where the product is made and the people who make it.

Kinda blew it on this one. The shoes were made in Guangzhou, China and we were unable to get on the line at the time of production. I would say this project failed this rule.

9. Every individual involved in the creation of the product must be credited by name.

Heddels team on this project is myself and Nick Coe. PF Flyers team is Christopher Tobias, Patrick Trubiano, Robert O’Donnell, and Nicole Underwood. Winter Session team on the shoe bags is Roy Katz and Tanya Fleisher. Fin Art team on the crates is Aaron Collins. The Studio Itself team on graphic design is Ross Evertson. Product photography editing by Ben McCarthy.

10. Products cannot be sold until the product is on hand and paid for by Heddels. No crowd-funding, no pre-sales, no net 30.

They’re crated up and ready to go in my living room.

11. A product’s retail price must not exceed twice the unit cost of the creation of the product.

We’re pricing these at $380, which is high, yes, but far from the most expensive sneaker we’ve featured and it doesn’t even cover production on these (plus, c’mon, there’s only 21 pair). This was a very expensive shoe, which should retail for much higher but PF was kind enough to subsidize their cost for release.

12. Products must be accompanied by an article documenting its design, sourcing, and production.

You’re reading it.

13. Products must be accompanied by a relevant souvenir, aka the “party favor”.

The bag. The pamphlet. The crate. This was a fun party.

14. All sales are final except in the event of a manufacturing defect.

Please don’t light your feet on fire and try to send these back.

15. Products must be sold by Heddels.

We have all the pairs that will be for sale. The raffle entry starts now.

Availability

Now we are a small blog operation and this is an extremely limited sneaker. We do not have the sophistication to counter bots that would probably crash our site immediately if we were to do a launch sale like our previous projects.

For this one, we’re doing a straight up raffle, which ended at 11:59PM ET on Sunday, February 11. 21 randomly drawn winners will be notified by 11:59PM ET on Monday, February 12 that they are eligible to purchase. If they decline or do not respond within 24 hours, we will draw until they’re all gone.

Godspeed!