Somewhere (hopefully hidden in a dark place), there’s a photograph of seven-year-old me, grinning and clad in a rather offensive mustard-colored fleece jacket trimmed with navy piping. If my expression is anything to go by then the jacket was a hit at the time, and I do have a few hazy memories of wearing this eyesore way-back-when.

Heddels editor, David, has a similar story, “I still remember when I was eight years old, when I first received an item made of fleece, or ‘Polartec’ as it was called at the time. It blew my mind that you could have something this soft, fuzzy, light, and warm all blended into the same material. Then I discovered it was made of the same thing as soda bottles.” It got us thinking about how the plush stuff is made and what makes it so good, so read on for our deep dive into its origins, construction and whether it’s still relevant in an increasingly eco-conscious world.

Where Does Fleece Come From?

Image via Jottnar

Despite getting its name from (and resembling) a sheep’s coat, ‘fleece’ is the term for the synthetic fuzzy fabric that’s almost exclusively made from polyester. It’s occasionally blended with natural fibers to enhance its texture, warmth or other properties. Before we get into the nitty-gritty of fleece’s origins, it’s important to understand how the fabric is made.

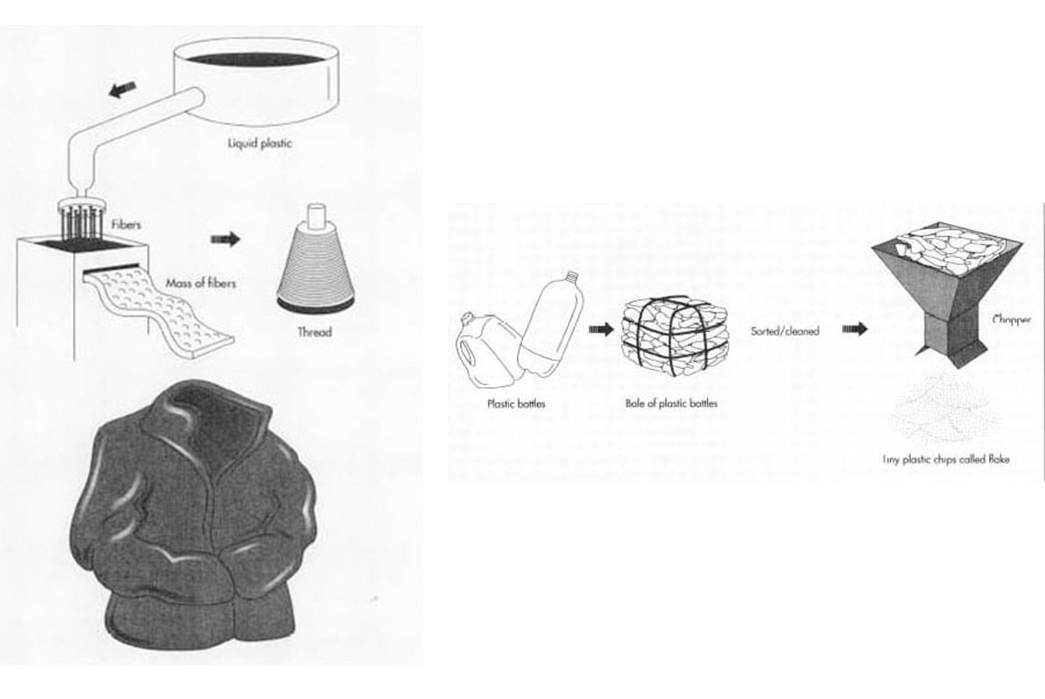

First, at around 302-410 degrees Fahrenheit, terephthalic acid is reacted with ethylene glycol, also known as antifreeze (stay with us). It’s heated again to even higher temperatures and, as it cools, becomes polyethylene terephthalate. The polymer is then forced through a series of tiny holes into a stringy consistency which hardens before being processed into yarn.

Basic diagrams of polyester manufacture and recycling plastic bottles

The material first came about in the 1970s, when Malden Mills—an American textile manufacturer that previously specialized in wool and faux fur—realized the potential of using man-made fibers to make imitation shearling. This embryonic material was the starting point for all the variations of fleece that exist today. It was soft, warm, quick-drying and breathable, and once a certain Yvon Chouinard got wind of the development, it swiftly hit the mainstream.

The history of Malden Mills is another story in itself. The company is technically still in operation, though it suffered a huge factory fire in the mid-’90s and several bankruptcies before being sold and becoming Polartec LLC, as we know it today.

Founder Aaron Feuerstein never actually patented fleece, and that’s why it’s so widely used across the world. Nevertheless, Polartec LLC remains the sole supplier of fleece to the United States military, The North Face, Patagonia, and many other outdoor brands, with an offering of more than 400 different fabrics.

Inside Polartec’s factory in Massachusetts.

Speaking of Patagonia, it was around 1979 when its founder’s wife, Malinda Chouinard, discovered Malden Mills’ fuzzy textiles in a Los Angeles market. The brand had been hunting for a reliable fabric to use in mountaineering gear that didn’t weigh or cost as much as wool, and Malinda knew she’d stumbled across the answer.

The small company had a few samples made up and tested them out in the mountains, realizing that although the fabric had its problems, it was ideal for the outdoors. “It insulated when wet, but also dried in minutes, and it reduced the number of layers a climber had to wear,” the brand explains. Over the next few years, Patagonia collaborated with Malden Mills to refine the pile and properties of its fleece, eventually resulting in Synchilla®, which the label still uses today.

Patagonia’s Synchilla® pullover

Not even a decade passed before other retailers began to incorporate fleece in their outdoor and sportswear offerings. Consumers, too, were impressed by its inexpensiveness and dense, yet lightweight hand that resulted in breathability and water-repellency. Thanks to its perennial popularity, the process of refining the fabric has never really halted, and nowadays its fibers are known to rival cashmere for their fine texture as well as increased resistance to pilling, a problem that plagued the textile for many years.

There’s also an assortment of extra treatments that can be used to enhance fleece’s weatherproof properties, but since they are often blended with strong chemicals, this can detract from the sustainable aspects of the fabric.

Is Fleece Sustainable?

Yes and no. The good part is that increasingly, fleece is made from recycled polyester (mostly using plastic bottles or old textiles), which is, of course, better than producing more virgin fibers. And if you’re vegan, then replacing natural wool fibers with synthetic fleece is a valid option. In terms of the carbon footprint of their manufacture, fleece and wool average out to around the same, however since the former has a better record of durability, it can be argued that this is the more sustainable choice.

The problem is that even when fleece is spun from recycled textiles, polyester still releases microfibers into the water when it’s washed, and on top of that, the fabric doesn’t biodegrade anywhere near as quickly as natural variations do.

According to a study by the University of California (and funded by our friends at Patagonia), the average synthetic jacket drops around 1.7 grams of microfibers into the washing machine, which makes its way to the water treatment plant and eventually out into the ocean. To help put a stop to this, you could try using a Guppy Friend, a washing bag that aims to minimize fiber shedding and microplastic pollution, but many argue that the solution ought to come from textile manufacturers.

Using a Guppy Friend can help to eliminate microfibers from entering the eco-system

Caring For Your Fleece

As we’ve mentioned, fleece is wonder-like in its resilience to wear and tear, but there are still a few things you can do to increase its life. In addition to using a Guppy Friend, you should also be mindful of using heat and excessive chemicals, like fabric softener, in the washing process, so put your fluffy items in the machine on a cold, gentle cycle and let them air dry. Alongside washing, you can easily maintain your garments with DIY repair jobs, like replacing a zip or patching up a hole.

If your fleece is well and truly worn out then don’t just chuck it in the trash, keep an eye out for local recycling options, or look into Patagonia’s “Reuse, Recycle” program, which will give your old items a new life.

If you take one thing away from this guide then don’t forget that, as always, investing in a good quality fleece from a trustworthy maker is the best way to go, as is caring for your investment in the right way to ensure it lasts years.

Lead image via Marc Richardson.