At Heddels, I’d say we have a pretty good understanding of that one blue and white but mostly blue fabric. You know, Denim? And I’m sure after perusing our site for a while, you’d have a pretty good knowledge of it, too. Whether you’re a passionate clothing enthusiast or not, let’s talk about a fabric you probably don’t know too much about – ripstop.

Ripstop is more than just a fabric with a bunch of square cells in it, it’s a fabric that transcended its military roots to become a go-to robust fabric in modern-day fashion. And for this reason, we’re taking a look beyond the fabric’s functionality to see where ripstop came from, how it’s made, and where you might find it today.

What Is Ripstop?

A close up of ripstop via ENGL 388

Ripstop is a lightweight fabric woven with a thick or double thread at regular intervals in a crosshatch pattern resulting in a grid-like appearance. The crosshatch effect is achieved during the weaving process and results in a fabric with a high strength-to-weight ratio. The intervals are typically 5 to 8 millimeters apart but this can vary depending on the application of the fabric.

Most commonly, and originally made from nylon, ripstop can also be made from cotton and even polyester. In a shocking twist of fate, its name is not a misnomer—it’s true, the beauty of ripstop is its resistance to tears. And even if a tear does occur, the raised cross-hatching will contain the tear to one area of the square cells. Smaller rips, easy to patch up.

Brief History of Ripstop

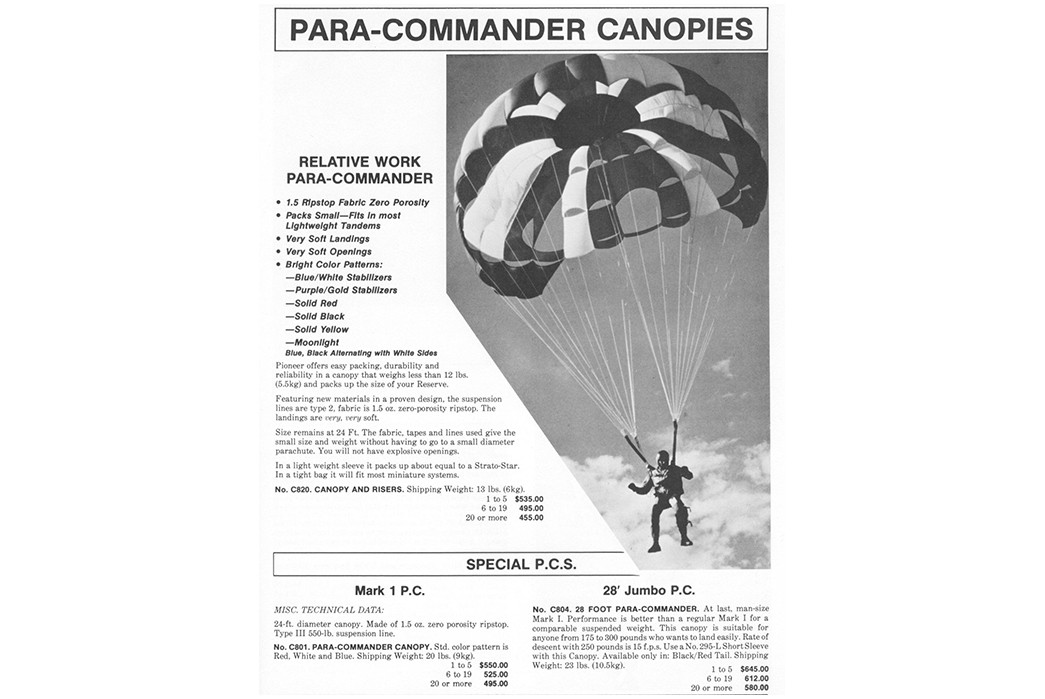

Image via Pinterest

The story of ripstop begins with the invention of nylon. In 1927, chemical giant, DuPont Company, began exploring the polymerization of organic compounds with the goal of creating a synthetic fiber. They were granted a patent in 1938 for the fiber that they christened Nylon. But nylon didn’t launch straight into hard-wearing garb and workwear. Its first applications were toothbrush bristles and hosiery.

Information surrounding the exact beginnings of ripstop nylon is a bit hazy, but like countless other clothing innovations throughout time, it gained notoriety in the military. During WWII, the U.S. Air Force was looking for a tougher, and more cost-effective silk-alternative for parachutes and nylon fit the bill. Parachute manufacturers are credited with designing the first-known ripstop nylon fabrics, although they probably looked a lot different to the typical ripstop of today.

As the years went on, manufacturers perfected the ripstop recipe and it was soon found all manner of garb and equipment. Uniforms, sleeping bags, tents, tarps, and even flags were among the swath of gear made from ripstop.

Common Ripstop Applications

So what’s up with ripstop now? As far as uniforms and tactical gear go, ripstop’s relationship with the military has only gotten stronger over the years and has spread to law enforcement, first responder, and just about any other physically demanding profession.

Converse CT 1970s Hi Quad Ripstop via Lost & Found

That’s not all though, in the world of the great outdoors, ripstop has a cult-like following and can be found on anything from jackets, pants, and footwear to hammocks, sleeping bags, tents. It has even found its way into tech wear, streetwear, and of course, heritage fashion. You will see brands with a military slant like orSlow, Engineered Garments, and WTAPS utilize ripstop on their military-inspired pieces, and brands like Filson, Nanamica, and Wander, and Snow Peak apply it to their bags and technical outerwear.

Engineered Garments BDU Jacket via Lost & Found