Finding high-quality heritage-centric sneakers is kinda tough. Outside of Converse 70s, which are mass-produced, there aren’t many options for top-quality pumps made by people give a shit. Luckily for those tapped into this niche, there are brands like Moonstar Japan.

Producing footwear in Japan for over 100 years, Moonstar is one of Japan’s finest makers when it comes to vulcanized sneakers inspired by both the brand’s Japanese heritage and early 20th-century American athletic sneakers. What sets Moonstar apart from other makers of these styles is that they are one of the only Japanese makers with access to traditional, kiln-fired vulcanization technology, which allows the brand to produce small batches of high-quality vulcanized sneakers, the likes of which are stocked at familiar retailers like Franklin & Poe, Blue in Green, and Redcast Heritage.

We caught up with Natsuko of Moonstar Japan to learn more about the brand and its rare production methods.

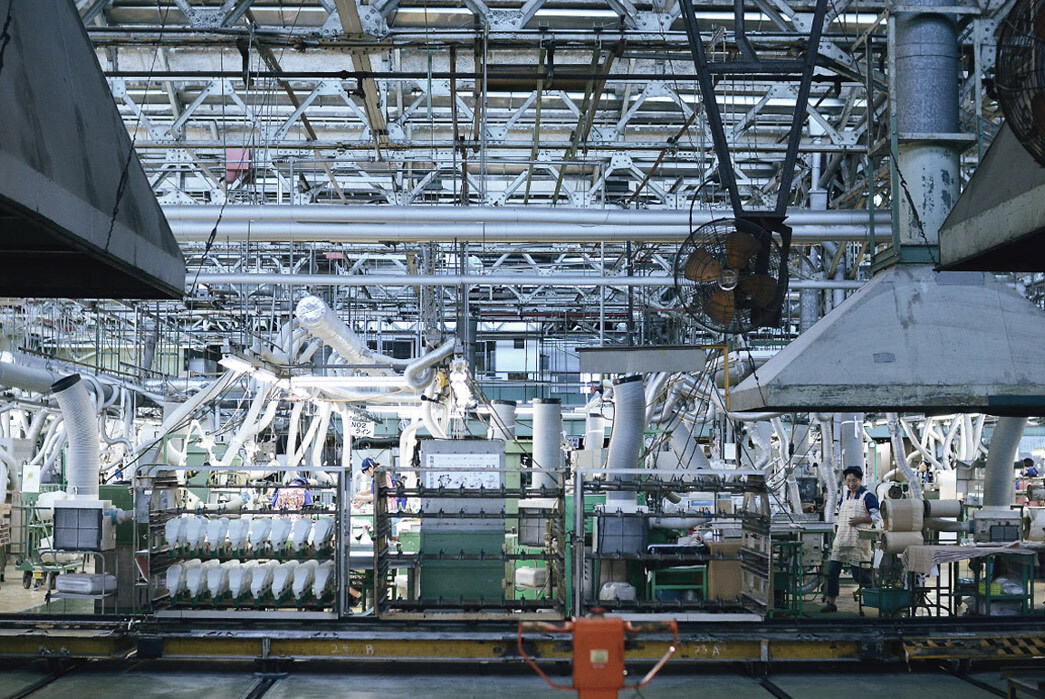

Moonstars Kurume factory, via Moonstar.

Hey, Natsuko. Thanks for taking the time to talk with us. When did you start working for Moonstar, and what is your role?

Hey James. I have been working for Moonstar for more than 10 years. I work as a design and sales assistant.

Tell us about Moonstar. When and why did the brand start and how did it become what it is today?

The company started in 1873 with the production of ‘zashiki tabi’ (room shoes with a tabi toe) for indoor use, and later developed the jikatabi in 1912, a tabi-style work shoe that had a rubber sole attached to it so that it could be worn outside. The company has since produced sneakers in line with the times and the company now offers a wide range of footwear, from children’s shoes to shoes for the elderly, students, and professionals.

The Japanese Vulcanisation series was launched on the occasion of the 140th anniversary as a series to reintroduce people to Moonstar’s craftsmanship. This is the series that has been introduced in recent years. This series celebrates its 10th anniversary in FW23.

A modern edition of Moonstar’s “jikatabi” Work Shoe. Image via Moonstar.

Talking about your brand, one of your stockists, Redcast Heritage states: “Japan did not have a history of shoe culture, but American culture inspired a small Japanese company to create a superior-quality product.”. Can you tell us more about this?

The culture of footwear, such as sandals and tabi, did exist, but the culture of leather shoes and trainers came from abroad.

While developing the jikatabi in the early 1900s, the company researched the vulcanization process as a method of bonding rubber soles to uppers. Taking a cue from overseas-made sneakers, Moonstar began producing trainers using this method.

Interesting! I actually think what is most attractive about Moonstar to us here in the West is how the shoes are made. Shop clerks often explain how the shoes are ‘baked’ during the vulcanization process. Can you explain the kiln-fired vulcanization process that is used in Kurume and Shikoku and perhaps tell us how it started?

The vulcanization process involves attaching a rubber sole with sulfur added to the pre-sewn upper, placing it in a kiln, and bonding it under heat and pressure. Before being put into the kiln, the rubber has the properties of putty rubber or a kneaded eraser, which would remain stretched once it has been stretched. When heat and pressure are applied to the sulfur mixture, a chemical reaction occurs, increasing its elasticity and strength. It will have the properties of rubber that are commonly associated with stretching and returning to shape.

This scientific reaction is also characterized by the fact that the rubber sticks very firmly, and by using rubber glue for the adhesive paste, a supple and strong shoe is produced that is hard to peel off the fabric upper.

The reason for starting the vulcanization method was the development of the aforementioned Jikatabi. When Jikatabi were being developed, the rubber soles were initially sewn to the upper, but because the seams were exposed on the bottom, the threads inevitably broke and the soles peeled off as they were worn. While Moonstar were struggling to find a better method, they saw a pair of vulcanized trainers from abroad brought by a German sewing machine technician and learned about a method of applying soles without the need for stitches, which they researched. Later, the company began producing trainers using its vulcanization process.

Moonstar Gym Classic, available for $240 from Blue in Green.

Can you explain the fundamental differences between the form of vulcanization that Moonstar uses and the ‘vulcanization’ that brands like Vans and Converse claim to use?

We have not personally seen the Vans or Converse factories, so we cannot say exactly what they do, but the fundamental manufacturing process itself is likely to remain the same. However, our process is much handmade, which may make a difference.

We also develop and manage our own rubber materials. The outsole and foxing tape are made of proprietary rubbers, each with its own specific performance characteristics that we have improved. Therefore, the flexibility and durability of the rubber material are excellent.

What are the benefits of your traditional Vulcanization method?

The shoes produced by this method have the advantages of incredibly strong, soft, and supple soles, as well as a beautiful silhouette. Above all, it is attractive for its elaborate and beautiful “quality of workmanship”, which can only be produced by skilled handwork.

Moonstar Gym Classic, available for $156 from Redcast Heritage.

The shoes made by Moonstar seem to take inspiration from early athletic sneakers from the USA and Europe – are there any Moonstar silhouettes with a distinctively Japanese influence?

Many of the shoes we are developing now are inspired by what Moonstar was producing in the 60s to 80s. Its original trainers may have been inspired by early athletic sneakers from the USA and Europe.

Although not a silhouette, the toe specification of our Gym Classic is actually very Japanese. The pattern does not flow down the side like a common basket type, but straight down towards the toe, a specification often seen in old Japanese athletic shoes and not so common overseas.

Thanks for taking the time to speak with us.

Thank you, James.

Moonstar Low Basket Camo, available for $154 from Franklin & Poe.