A short drive outside of Milan lies Candiani, a denim mill which has been in operation since 1938. This Italian powerhouse has provided denim to some of the heaviest hitters in the fashion world, is one of the few heritage producers of selvedge fabrics, helped pioneer the development of stretch denim, and has made strides in sustainability.

While technological innovation, informed business development, and coordinated expansion have all played a role in these achievements, what is perhaps more pertinent is the development of a community.

The mill is currently under the innovative leadership of Alberto Candiani, fourth generation owner of the company. Some of the staff on-site at the mill have ancestors that worked at the mill under the direction of Luigi Candiani, Alberto’s great grandfather. His grandmother still lives on the premises in a family home opposite the factory.

Alberto Candiani in his natural environment – on-site at Candiani Denim.

Gianluigi Candiani, Alberto’s father, is still involved in the operation of the mill, but leaves the running of the business to his son. Some segments of the mill are run by families who have worked in this area for decades, be it weaving or dyeing. Walking the Candiani premises is akin to roaming a small village, where everyone knows one another and family heritage goes back decades.

There are currently nine families who have reached third generation with the company and Candiani is very clear that “the great people are our most important asset.” So much so that they worked with employees to design a denim collection based on the jeans they wore when working in various roles and in different areas of the mill.

Image via Denim Freaks.

Although the company’s current efforts are largely focused on sustainability and advancements in production, the heritage of the mill plays just as large a part in the future of the company. It is this juxtaposition, a balance of new and old, which makes Candiani Denim a leader in the industry.

During the company’s second ‘Open Mill Day’, we took a tour of the factory and looked at the inner workings of this denim giant. So read on to understand more about this green mill which paves the way in a sea of blue.

Candiani’s History and Heritage

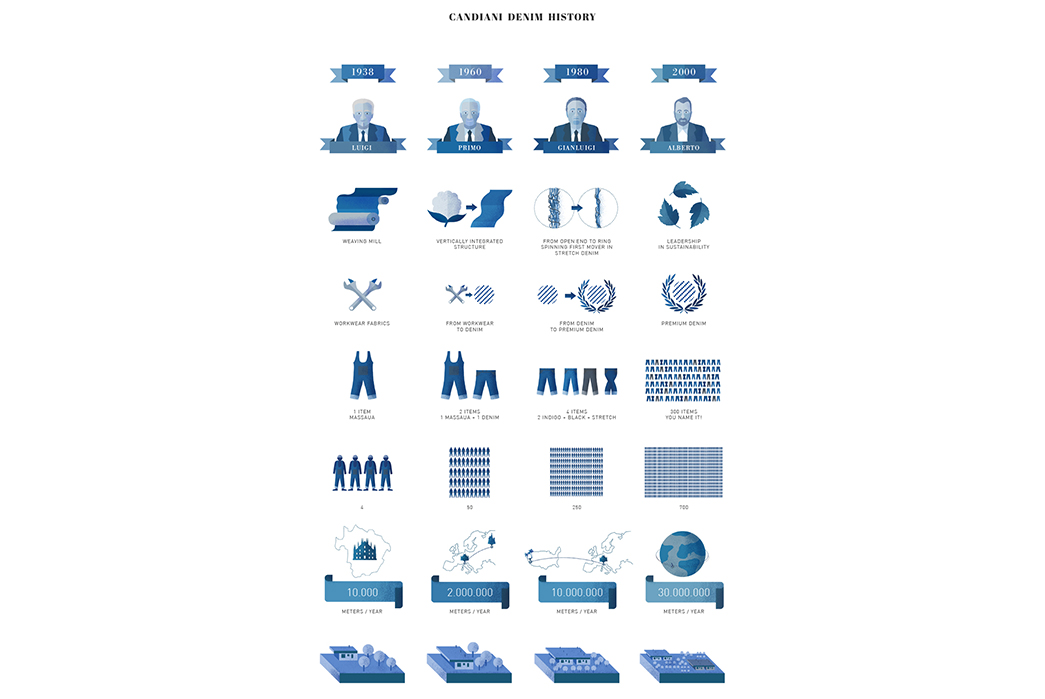

The history and lineage of the Canidai Family and Denim Mill (Image via Candiani Denim)

In 1938, Luigi Candiani set up the mill just outside Milan for the primary purpose of weaving. With workwear fabrics as their focus, they began making 10,000 meters of fabric per year.

With just four employees this was an ambitious undertaking. But after WWII, things needed to be taken a step further. In 1960, Luigi’s son Primo converted the factory into vertically integrated denim mill. This kickstarted denim production and was supported by a huge increase of staff to 50 workers. The result was the production of 2 million meters of fabric per year. While this marked a significant advancement for Candiani, the Italian innovators didn’t stand still for long.

The inner workings of the Candiani Denim machine.

Primo’s firstborn, Gianluigi, took the helm in 1980 and launched Candiani into the world of premium denim. The main change came in the production of the yarn, with a move from open-end yarn production to ring spinning, as well as focusing on high quality stretch denim.

During this time, Candiani’s staff jumped to 250 and production reached the heights of 10 million meters per year. 20 years and many milestones later, the mill came under the leadership of its current owner Alberto Candiani in 2000.

Carrying on the legacy of his ancestors, Alberto has made sustainability and advancements in conscious production a priority. Continuing to be inspired and shaped by not only the local environment but the global landscape, Alberto has continued to grow the company to three times it’s previous annual output as well as investigating innovative solutions to the industry’s obstacles.

The Natural Environment & Sustainability

A snapshot of Ticino Park, just outside of Milan (image via Where Milan)

One factor which has significantly influenced the development of and production at Candiani is the surrounding environment. The mill itself is situated within a nature reserve and as a result is subject to strict environmental rules and regulations. Sitting between Milan and the Alps, Ticino Park follows the course of the River Ticino and boasts a diverse ecosystem that includes forest, moorland, and water courses.

Candiani claims the local environmental regulations are stricter than those of any other denim mill. But rather than move the company to an area which had fewer environmental constraints, this became a point of pride and principle.

While sustainability and environmental awareness are now ‘trends’ and the hottest buzz words within the fashion and garment world, Candiani was pioneering this approach for decades before mainstream media and fashion publications were preaching to the public about conscious consumption and the harmful impact of the fashion on our natural world.

As Europe’s largest denim mill with two plants covering 85,000 square meters of production, Candiani have continued the tradition of local textile manufacturing and brought it into the twenty-first century in a way which coexists with the natural environment that surrounds it.

A closer look at the Candiani Dye House where the cotton gets its deep dip into indigo.

Central to the production and product at Candiani is ‘Reduce, Re-use, Recycle’ principles. For example, Candiani’ water saving dyeing technologies ‘N-Denim’ and ‘Indigo Juice’ allow the mill to save 2,300 cubic meters of water, 9,450kg of chemicals and 44,000 cubic meters of energy (the equivalent of the average consumption of 31 families annually).

The mill also utilizes Kitotex which is another technology that drastically reduces the consumption of water, chemicals and energy. In addition, dyestuff is never discarded but stored and re-used, as well as re-using the water from the finishing department in the dyeing process.

The remnants of cotton from the weaving, spinning and dyeing processes are collected and recycled to create yarns which forms the basis of the Mill’s recycled denim line. Whereas many mills only look after one part of the supply chain, Candiani’s vertical integration affords many opportunities to re-use and recycle, and futher reduce the overall carbon footprint.

The Materials

Candiani has been developing more sustainable denim practices for decades, and the mill understands that sustainability, quite literally, has to start from the ground up. Organic cotton, recycled yarns, hemp and linen fibers are used in the weaving process, as it reduces the impact of water usage, chemicals, and fertilizers in the growing process.

This is supported by the adoption of Better Cotton Initiative (BCI) fibers which make up for 40% of Candiani’s overall production. BCI ultimately supports those who produce cotton, it improves the environment that the cotton is grown in and increases transparency about the supply chain.

Artificial components also have a part to play in reducing the environmental impact of the mill. Here we can see fibers like Tencel and Micromodal alongside cotton in denim production, which results in a minimized impact on the environment through the use of sustainably managed trees farms and reduced water consumption.

Candiani also uses Refibra fibers in production, which further utilizes the waste and scraps of production. The end product is a denim which retains the strength of traditional cotton, but is softer to handle.

Moving onto the dyeing process, the Candiani is in the 15% of mills worldwide that only uses pre-reduced indigo. Pre-reduced is more sustainable than powder indigo, but comes with higher price tag that the mill thinks is worth the extra cost.

The impact of pre-reduced indigo is that it reduces two common chemicals used in production with 52% less sodium hydroxide and 63% less sodium hydrosulphite. Candiani’s advanced formula has been awarded eco passport, GOTS approval and meets European REACH requirements.

For the consumer, it’s easy to ignore the finer details and plead ignorance when it comes to where your garment is manufactured. But that’s changing and we’re now in a world where the consumer often wants to be armed with the facts before they make a decision of where, or what, to buy.

One of the many washing machines at the Candiani Mill.

Jeans undergoing their final finishing treatments at Candiani.

The blueprint for a Candiani denim is a complex, considered and intricate process. From deciding whether the yarn should be ring or open-end spun to whether the denim is woven on vintage shuttle or modern projectile looms, the process is thorough to say the least.

The Development Center

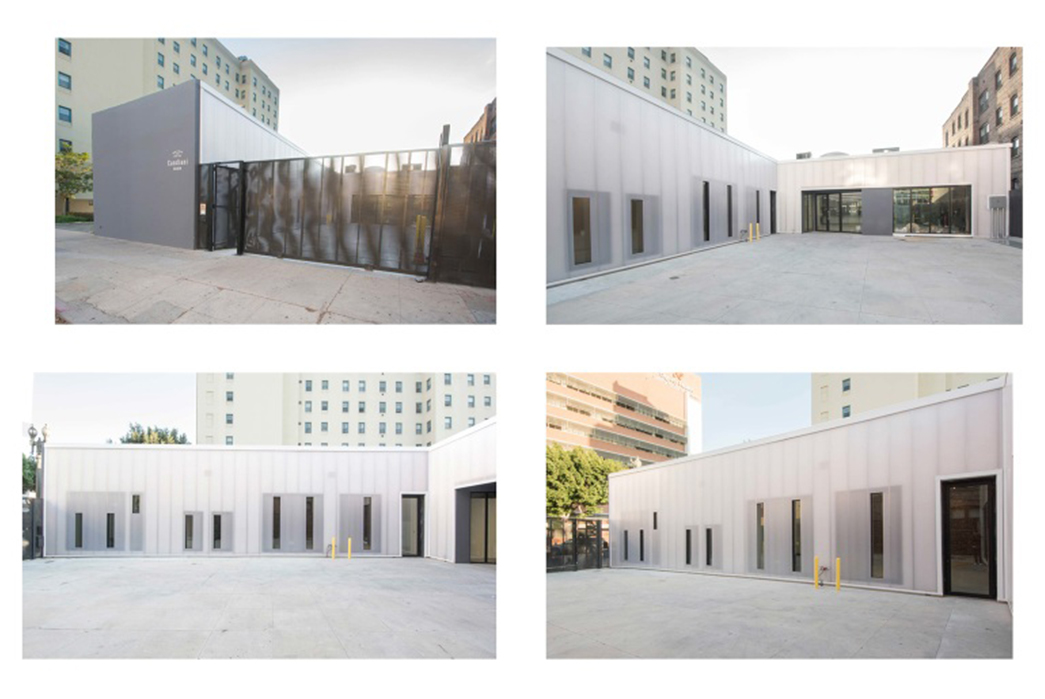

The Candiani Development Center in Downtown Los Angeles (image via Paul Trussler)

In the heart of Los Angeles, lies the Candiani Development Center. The Development Center is part of the Mill’s efforts to merge sustainability and style. Showing designers the potential of a single piece of fabric and what can be achieved through different techniques and processes.

One result of the Development Center’s work is the creation of ‘wash instructions’ which allow designers and brands to take their experience and produce the most eco-friendly wash with their chosen fabric. But this is more than just a kitchen making a ‘denim recipe’ for anyone willing to pay the price.

This is scientific analysis. This is methodical. The aim, the hypothesis, is to create the best match of fabric to treatment for each subject. True to the core philosophy of Candiani under Alberto’s direction, this is where innovation leads to sustainability.

Inside the Development Center in Downtown Los Angeles (image via Paul Trussler)

Of course, there is a benefit to the mill being based only blocks from the Staples Center in Downtown Los Angeles and on the doorstep of the premium denim industry on the West Coast, but the strategic position allows the mill to broaden its reach beyond Europe and to define the future of premium denim through sustainable practice.

Alberto with Maurizio Donadi of Aterlier & Repairs (image via WWD).

What Candiani is doing through its Development Center is helping to train an industry in the tactics of future sustainability and environmental awareness, including the next generation of designers at the nearby Fashion Institute of Design and Merchandising.

The Future

With 80 years under their belt, what is next for Candiani? (Image via Denim Freaks)

For Candiani, transparency is key and it will continue to be under Alberto’s leadership. Having a strong distaste for greenwashing and ‘Eco-BS’, Alberto speaks plainly about how the business operates; “At Candiani we try to make our sustainability very tangible in terms of product R&D and extremely transparent when it comes to marketing”.

Reflecting on the issue and ‘trend’ of sustainability, he notes that “I feel kind of responsible here cause I personally launched this ‘sustainable trend’ over ten years ago”.

But this is more than a trend or passing movement, this is the future of the denim industry and while many are jumping on the bandwagon, Candiani are holding the reigns and steering the ship, for a greener blue world.