At the heart of Maine’s shoemaking heritage is the moccasin. New England colonists adopted Native American footwear well before the United States gained independence. Native footwear was much easier and more resource-efficient to craft than European options. As crafting techniques from Europe and North America blended, a distinctly American style of shoemaking evolved. Machinery evolved through the nineteenth and twentieth centuries but hand sewing remained at the heart of the practice. For generation after generation, some of the greatest shoemakers in the world cobbled away between Connecticut and the Canadian border.

Hand assembling a pair of Easymocs in Maine. Image via Easymoc.

Sadly, this robust and proud industry fell into decline shortly after World War II. American shoemaking, like so many robust creative industries, became the victim of offshoring, technological innovation, and the general cheapening of manufactured goods during the back half of the twentieth century. Today, only a few dozen people remain who possess the expertise to handcraft shoes the old-fashioned way. By the grace of diehard enthusiasts, some of the century-old machinery remains but there are barely enough people left who know how to use it.

Quoddy uses vintage equipment to hand-make every shoe. Image via Quoddy.

As the light of New England shoemaking flickered, upon the verge of fading away forever, a few brands emerged to stoke the flame like so many bellows. In the northeastern tip of the United States, just enough masters of hand-sewing footwear remained to foster these hopeful young cobblers. The nearly broken chain of passing the required skills down from one generation to the next was mended, if only tenuously. When demand for exceptional craftsmanship in footwear and leather goods exploded around the year 2010, Maine answered the call with moccasins and so much more.

All Roads Lead Back to Bean

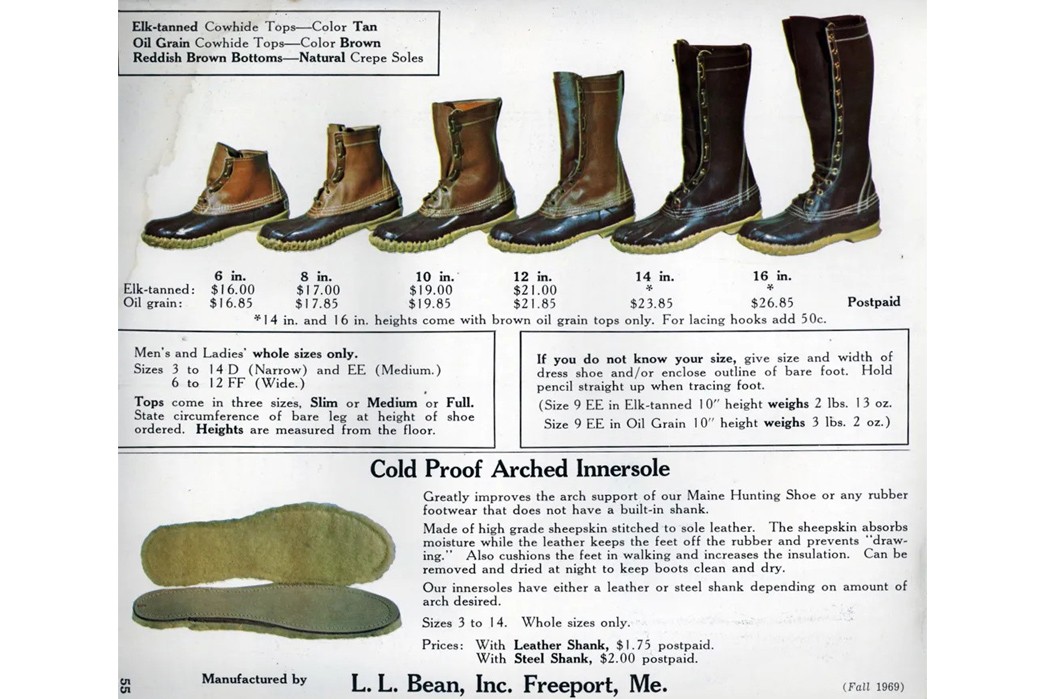

Fall 1969 advertisement for the L.L. Bean Maine Hunting Boot. Image via Pinterest.

Three brands are leading the charge to reestablish Maine’s once-thriving shoemaking tradition. Rancourt, Quoddy, and Easymoc are three very different brands with very different backstories, but all three share a passion for high-quality footwear and a reverence for the legacy they now shoulder. However, there is another Maine retailer that has been a prestigious influence on these younger brands. Easymoc plainly attributes the L.L. Bean Camp Moc as the inspiration for the aesthetic of the brand. The influence of that same shoe, invented in 1937, is evident in both Rancourt and Quoddy.

L.L. Bean is not only the most famous footwear and apparel brand from Maine, it is one of the most iconic brands in America. While the famous Camp Mocs are still “handmade,” it is done outside of the United States. The purveyors of all things outdoors and the New England aesthetic have long since scaled past the ability to produce most products domestically. Even though the famous Camp Mocs are still “handmade,” it is done outside of the United States. With the notable exception of the brand’s most famous creation: the Maine Hunting Boot, better known as the Bean Boot.

Hand assembling Bean Boots at the Brunswick, MN factory. Image via L.L. Bean.

A 117,000-square-foot factory in Brunswick, MN produces every pair of Bean Boots from start to finish. The distinctive rubber bottom, a single piece of rubber to ensure water tightness, is made by a machine. From there, every additional step is done by hand, “using a mix of new and old technology,” according to the senior manager of manufacturing, Royce Haines.

Each boot takes an average of 85 minutes to produce by a staff of 200, splitting their time between three shifts. The signature triple stitch that connects the upper to the bottom is required for waterproof integrity, but mastering the special sewing machine and technique to accomplish this stitch takes years. While L.L. Bean could recruit from a ready labor pool of skilled needleworkers in the Freeport, MN area 50 years ago, staffing has become a major challenge.

The signature Bean Boot triple stitch creates a water-tight seal. Image Yahoo! Finance.

A Man and His Machines

Quoddy loafers feature hand-stitched uppers. Image via Quoddy.

The story of how Kristen and Kevin Shorey acquired the skills and equipment necessary to start Quoddy sums up the challenges faced by all traditional Maine shoemakers. In the late 1990s, the couple acquired Kevin’s grandfather’s sporting goods store in Perry, MN. It didn’t take long for them to notice that customers routinely sought out handmade shoes crafted by local Thomas Kennedy in his barn.

Kennedy was a master of hand-sewing moccasins and crafting leather shoes. He represented a very old but dwindling tradition of passing down shoemaking skills from one generation to the next. When the Shoreys ment Kennedy in the 1990s, few people remained who could match his expertise in hand sewing moccasins. So it was a devastating blow when Kennedy fell into poor health and was forced to retire and sell his equipment to a couple in Florida. The Shoreys attempted to work out a deal with the new owners of Kennedy’s equipment to provide moccasins but the quality was sorely lacking.

Hand-finishing the welt on a pair of Quoddy loafers. Image via Quoddy.

Unable to find an adequate replacement, the Shoreys purchased the old shoemaking equipment from the Florida couple and shipped it back up to Maine. If they couldn’t find someone to make moccasins for them, the Shoreys would learn to make moccasins for themselves. Fortunately, Kennedy had sufficiently recovered at this point to teach the aspiring shoemakers how to use the equipment and all the other requisite skills needed to carry on his tradition. In the kind of twist-of-fate behind so many of life’s great accomplishments, the Shoreys became the newest generation of apprentice Maine shoemakers in the early 2000s.

In a tie back to L.L. Bean, an early collaborator with Quoddy was Alex Carleton, the head designer for Bean’s Signature Collection. Quoddy has done multiple collaborations with Maine’s most famous brand, including putting on hand-sewing demonstrations at the Freeport flagship store. If you’re looking for an authentically hand-made alternative to L.L. Bean’s Camp Moc, the Quoddy canoe shoe is a spitting image with all the bonafide.

It’s Hard Work and Not Easy on the Body

The original Easymoc mule-style moccasins. Image via Easymoc.

Getting into hand-stitched shoemaking has to be a labor of love, according to Easymoc founder Greg Crodiero. Like any good love story, Cordiero’s started out with a fortunate crossing of paths while searching for something else entirely. “I went up to Maine to take a look at a sewing machine for sale with a buddy who wanted to do some leather work for fun.” He explained, “We just so happened to stumble across a garage with two old hand sewers making shoes for themselves and selling them on eBay.” That chance encounter sparked a passion that would eventually lead to Easymoc and a commitment to keeping Maine’s shoemaking industry alive.

Cordiero spent over a decade in the shoe industry before launching Easymoc in 2020. He started out at German sportswear behemoth Puma, eventually working his way up through companies including Timberland and Huckberry. Time spent at those enormous and very modern brands taught Cordiero how to navigate the modern footwear industry. Simultaneously, he and his friend were learning how to make shoes the old-fashioned way. “As we started making shoes, it became a game of telephone with each new person we met or hired, introducing us to another.” However, if you want to make shoes the old-fashioned way and make a mark in the modern shoe industry, it takes more than two guys.

Easymoc uses specific vintage machinery, like this Little Way sewing machine, to make shoes the old-fashioned way. Image via Easymoc.

When asked about the difficulty of finding skilled labor in Maine, Cordiero was bluntly honest. “Right now we employ 13 workers, 5 of which can hand sew. It is extremely hard to find people who hand sew, there really aren’t many left.” Communities all over Maine used to foster hand sewing but those days are long gone. “What is even harder,” Cordiero elaborated, “is finding people that want to learn and stay at the bench for us to retain that talent.” Labor intensity is just an unavoidable part of sticking to the hand-sewn tradition. “It’s hard work and not easy on the body.”

Easymoc has made a name for itself in a relatively short period of time. Credit Cordiero’s substantial industry experience for this admirable growth. Even when you’re making shoes the old-fashioned way, it takes a modern approach to marketing, clienteling, and distribution if you want to have any success. Savvy social media and web placement, combined with good ol’ fashioned word of mouth, have complemented Easymoc’s exceptional shoemaking.

Hand-stamping leather to make a pair of Easymocs. Image via Easymoc.

If there is hope on the horizon for Maine’s once glorious shoe industry, this is where Cordiero sees it. “I believe we can keep the trade alive, but in a small way,” he explained. “Sadly, the volume of hand sewing just isn’t possible like it once was 50 years ago due to rising costs and an overall different way of life.”

Help Where You Can Get It

Rancourt & Co. shell cordovan cap toe boots. Image via Rancourt.

Rancourt is a Maine shoe company with a much older history than Easymoc but takes an equally balanced approach to keeping traditions alive by infusing modern innovations. In 1967, David Rancourt opened a factory in Lewiston, MN to produce handmade moccasins. His son Michael joined the family business in 1970 and expanded the line to include luxury items like calfskin loafers. After changing ownership in the 1990s, the company faced closure in 2008. That’s when Micahel and his son Kyle bought it back and rebranded it Rancourt & Co.

Since relaunched in 2009, the father and son Rancourt duo have been committed to the kind of heritage shoemaking that used to be found throughout New England. At the heart of every shoe is the hand sewing. As the company’s website proclaims, “Our current team of six hand-sewers has close to 200 years of combined experience. One individual has been hand-sewing for four decades; two others have fifty years of experience combined.” This means that finding enough proficient sewers to meet demand has become a challenge as Rancourt grows in popularity.

Hand sewing is the foundation of every Rancourt shoe. Image via Rancourt.

In 2022, Rancourt turned to offshore labor in an unconventional way to meet increasing demand. Three-hand sewers in the Dominican Republic were contracted to start shoes that are then shipped to Maine for finishing. Essentially, the uppers for moccasins, loafers, and boat shoes are sewn together in the Caribbean then all the sole construction is done stateside. Rancourt confessed that this measure does not save them any money, perhaps even costing more, but it is done solely to meet demand without sacrificing quality.

Keeping the Craft Alive

One of Rancourt’s master hand sewers, keeping the craft alive. Image via Rancourt.

Mainers are known for being proud and sturdy. Those who can handle the rough Atlantic coastline, seemingly endless wooded mountains, and notoriously harsh winters, get to live amongst some of the greatest natural beauty in the world. You have to earn a life in Maine the old-fashioned way, but the rewards are irreplaceable. So too, it seems, is the case with carrying on the Maine shoemaking tradition.

There is hope that Quoddy, Easymoc, and Rancourt represent a new beginning for a once-flourishing local industry. Though realities of the modern world should temper expectations. “My goal,” Cordeiro noted, “is of course to keep [Maine shoemaking] alive at any capacity we can, but as the world progresses, technology marches on, and the craft of hand sewing becomes a shadow of its former self.” Any skill can only survive as long as people are dedicated to learning it.

According to Cordeiro, “To secure a thriving future, Maine’s artisans need to focus on innovation, sustainability, and marketing to a wider audience while preserving our heritage and commitment to quality craftsmanship.” Indeed, the only way forward is to strike a balance between the old ways and the new. For now, this cottage industry is standing strong within the modern footwear industry, like a lighthouse on Maine’s infamously tempestuous coast. We can only hope that the future holds brighter days.

Maine-Made Mocs

Rancourt Baxton Ranger Moc, available for $328 from Rancourt & Co.

Easymoc x Division Road Rambler 3-Eye Moc, available for $365 exclusively from Division Road.

American Trench Horsebit Loafers (produced in Maine by Easymoc), available for $295 from American Trench.

Quoddy Canoe Shoes, available for $249 from Quoddy.