I know the items we feature are often expensive, I can’t afford the majority of them myself. In the days before I learned how to sew, I would catch myself thinking, “Why don’t I just make it myself? How hard could it be? “ Only later would I learn the agony and the ecstasy of design, sourcing materials, and clothing production and that these high-dollar items are actually very reasonably priced when you break it down on a spreadsheet.

Well in 2012, Daniel Skinner had that thought and then, much more impressively, he followed through on it. Today, he runs Skinner American Goods, where he produces a full line of jeans, jackets, shirts, and work pants in his Tallahassee, Florida workshop.

We’re taking a look at Daniel’s operation today and how to grow a One Man Brand in 2024.

Bedroom Beginnings

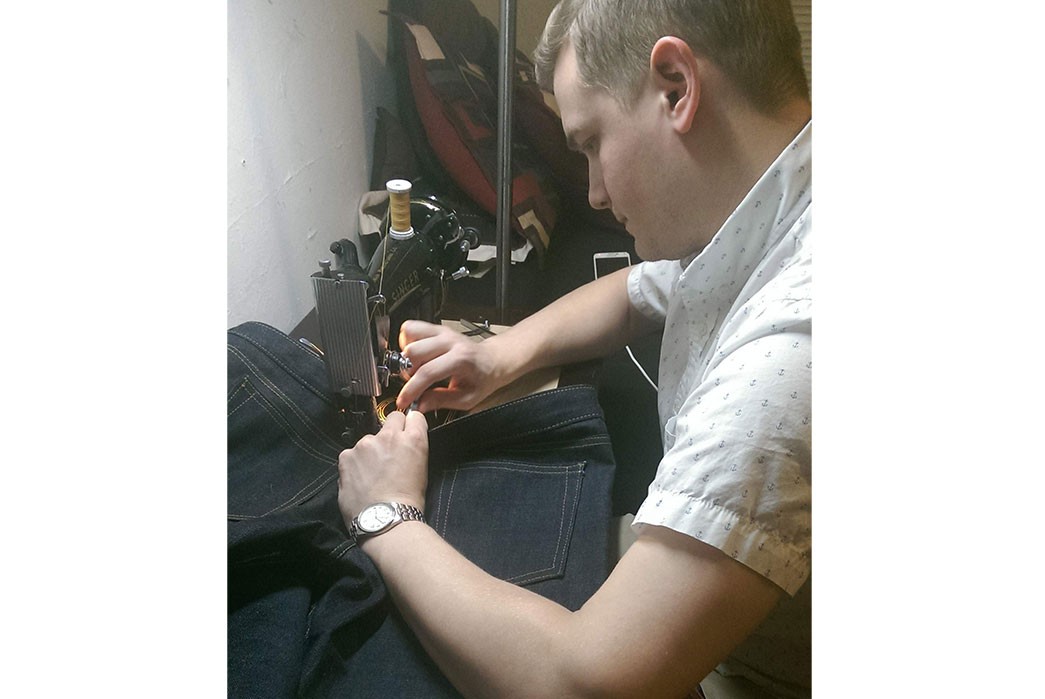

Daniel Skinner at his first thrift store acquired sewing machine in 2013.

Like many of us, Daniel’s interest in clothing developed in college. But, also like many of us, his taste soon outpaced his budget and led him to the “I bet I could do that” stage. When he saw a vintage Singer sewing machine in a thrift shop, he took it home and put that idea to the test.

In addition to his academic studies, Daniel dove deep into sewing techniques, fabrics, pattern making, and all other aspects of garment production. He recounts, “I got really obsessed with it pretty quickly and within a few months I was spending all my free time learning how to make clothes.”

Faded Rugged Workwear collab Work Pants in Italian double indigo selvedge and a pair of Deadstock Kaihara selvedge jeans faded by Daniel.

This was in 2012, the early days of Instagram, Youtube, and a plethora of other internet resources, so a lot of Daniel’s experience came from trial and error and hounding people who looked like they knew what they were doing with messages. “There were so many prominent makers who helped me along the way. Everyone in this small brand denim maker community is so incredibly helpful and encouraging. We’re all friends behind the scenes.”

The nurturing from that community would help him become a part of it.

Launching into a Brand

Daniel Skinner fitting a customer for a custom pair of jeans circa 2018.

By 2018, with a few contract sewing jobs under his belt, Daniel felt ready to start his own brand and launched with three items: jeans, chinos, and shorts.

Production was literally in-house, he had crammed nine vintage sewing machines into a 120 square foot spare bedroom. The concept was simple, he wanted to make thoughtfully designed, responsibly sourced, and carefully crafted garments to the same durability standards of the machines he sewed on.

A Skinner Sashiko Jacket in 12oz. Japanese indigo fabric.

And Skinner goods combine expertise from all over the world to exemplify that ethos:

- All raw materials are sourced from the U.S., Japan, or Italy for their rich textile history but also higher labor and environmental standards

- The garment pattern system comes from a German tailoring method designed for one-off production

- And all the little details like flat-felled stitching, leather-backed buttons and rivets, and swing-action backs on the jackets

Skinner Today

Daniel in front of his Tallahassee storefront.

Daniel has only expanded on that starting philosophy. He’s made it out of sewing in a bedroom and you can find him in his retail space and workshop in the Railroad Square Arts District in Tallahassee, Florida.

Today he offers eight garments in 20 different fabrics, all still made-to-order on vintage machines by himself or one other employee he’s taken on.

Inside the Skinner American Goods workshop and storefront.

If you’re looking to try a Skinner offering, Daniel suggests their Ranger Jacket, “I spent the better part of a year refining this design and it’s my favorite thing I’ve ever made.” He offers it in a heavy 20oz., 100% made in USA, Berry Amendment Compliant waxed canvas as well as a 16oz. waxed woodland camo.

It has sleeve patches from the elbow to the cuff for durability, double snap flap pockets, rounded pocket edges and cuffs which are less likely to snag on things while working. His favorite detail is the action back for full range of motion, “We added a specially designed interior panel which returns the pleats to the closed position for comfort and a cleaner silhouette when not in use. Like most of our garments, the fit sits right in the sweet spot; a slightly tailored silhouette with plenty of room to move and layer.”

The Skinner American Goods Ranger Jacket in 20oz. Waxed Canvas.

Daniel also just released a 22oz. Japanese selvedge denim collection. Heavyweight denim is notoriously difficult to work with from a technical standpoint, and it required retooling and beefing up some of his machines.

Looking ahead, expected releases include some of their first non-denim pants this spring, some new colors of their 12oz. sashiko fabric in the summer, heavyweight flannels in the fall/winter, and potentially women’s fits in 2025.

A pair of 22oz. jeans from Skinner’s Heavyweight Japanese Denim Collection.

Only 2-3% of clothing in the US is produced here and an even smaller percentage of those brands are doing it all under one roof. Daniel’s goal is ultimately to help you develop a closer relationship with the clothes you wear and the people who make them. When you call, email, or drop by Skinner, you’ll talk to the same person who designed and performed every single operation in the production of your shirt, jeans, or jacket.

Or if you’re looking for sewing tips because you also mistakenly thought, “How hard could it be?” he’s there to help.

You can find Skinner American Goods at their website, on Instagram, or at their location 625-8 Railroad Sq, Tallahassee, Florida.