Denim jeans could be the most popular item of clothing on the planet. Chances are you already own (at least) one pair of them and you’ve probably also heard about the cultural phenomenon that is Raw Denim.

If you only know whispers of the discomfort associated with raw denim, the supposed high cost, or even about people putting their jeans in the freezer, then this post is for you. We’re here to explain exactly what raw denim is, some basic raw denim terminology (selvedge, fades, etc.), and how you to care for it.

After reading this post, you should understand what the hype is all about and be able to make an informed raw denim purchase.

What Is Raw Denim?

Selvedge raw denim fabric.

Raw denim (aka dry denim) is simply denim fabric that remains unwashed, untreated, and virtually untouched from when it rolls off the loom to when it is sold to you. It’s denim in its purest form.

Raw denim usually has a crispy and stiff feel and easily leaves traces of its indigo dye behind when it rubs against another surface–even your hands (this phenomenon is called crocking). Be careful what you rub up against when wearing a new pair of raw denim jeans, you might leave a bit of blue behind.

The Benefits of Raw Denim

So why go through all this hassle just for a new pair of jeans? One of the biggest benefits of raw denim, and the indigo loss, is that they develop and age based on what you do in them and to them. Every mile you walk, every scrape on the concrete, every item you keep regularly in your pocket leaves its mark. The dark indigo dye slowly begins to chip away revealing the light electric blue and eventually the white cotton core of the denim yarns the more you wear them. What’s left is a wholly unique garment that was formed and faded to you and you alone.

Take a look at this pair of Pure Blue Japan jeans below. The pair on the left is brand new, and the pair on the right have been worn for just over a year. If you want to see more examples of faded raw denim, check out our Fades section.

Other benefits of raw denim include:

- Greater Durability – Since the fabric has not been artificially stonewashed, lasered, and sandblasted, you get the full life of the fabric involved, hence why many vintage garments have lasted so long.

- More Eco and Labor Friendly – It takes an awful lot of water to grow enough cotton for a pair of jeans, but washing and distressing them takes even more, an average of 42 liters per jean. By buying raw, none of that water needs to go to waste. It also doesn’t expose workers to the harmful chemicals often used to distress and wash denim.

- Less Clutter – Many raw denim fans will wear the same pair of jeans everyday for months or years at a time. This could very well be your only pair of pants!

- Greater Value – Although the cost of entry is often high, the greater durability often leads to many more wears per pair.

The History of Raw Denim

A pair of Levi’s 501 jeans from the late 1880s.

While the vast majority of denim jeans sold today are distressed and washed before you buy them, nearly all denim was sold raw and crispy up until the 1970s. Denim was primarily a workwear fabric–hence the term “blue collar”. Denim was sturdy and tough, but still relatively soft, flexible, and comfortable once it was broken in.

The word denim comes from the original name of the fabric “serge de Nimes”, serge meaning sturdy fabric and de Nimes meaning of the town of Nimes, France. There is some contention over whether denim was actually developed in Nimes, but everyone agrees that there is one event that solidified denim jeans as we know and love them today.

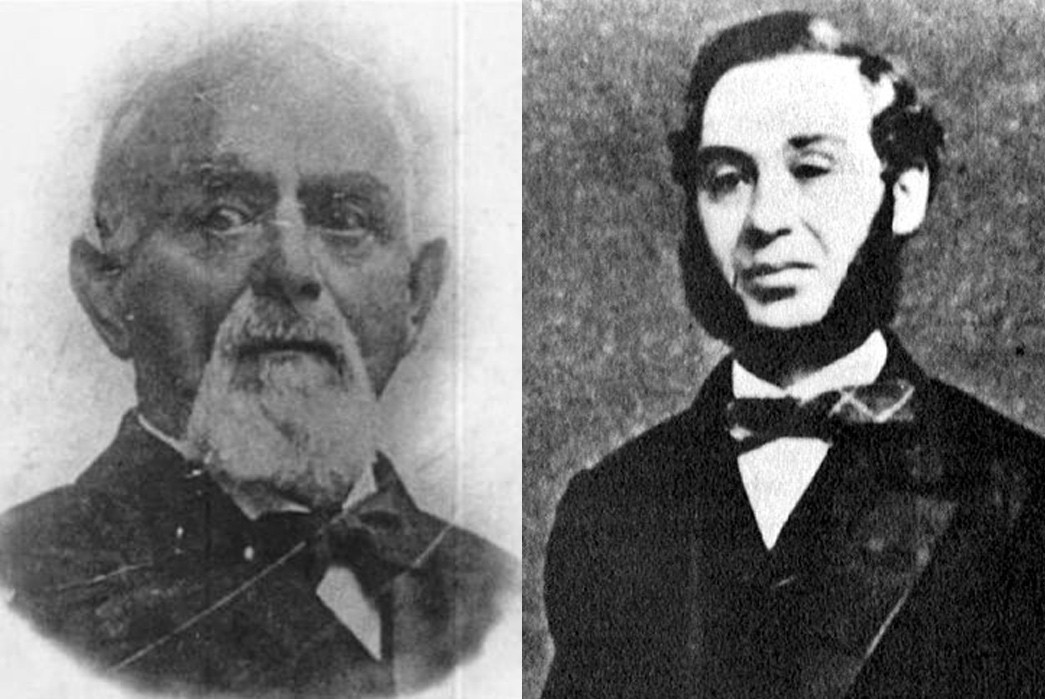

Jacob Davis (left) and Levi Strauss (right)

In the early 1870s, a Latvian immigrant tailor named Jacob Davis was producing clothing for miners in Reno, Nevada. Davis had developed a new way to secure the stress points on pants–copper rivets. Miners were thrilled with the increased durability and Davis tried to capitalize on the discovery by patenting his invention but had failed several times at the patent office.

Davis reached out to his fabric supplier in San Francisco, Levi Strauss, a Bavarian dry goods merchant, about going into business together. Strauss and Davis received the patent in 1873 and soon began making the riveted denim jeans “waist overalls” that would define the how we think of jeans today.

Denim jeans were about as far away from the fashion world as possible at this point–it was pure utilitarian function. If anyone cared to look at the brand or the make of their denim, it was purely to see which one would hold up better under abuse. This would be denim’s identity through the early twentieth century.

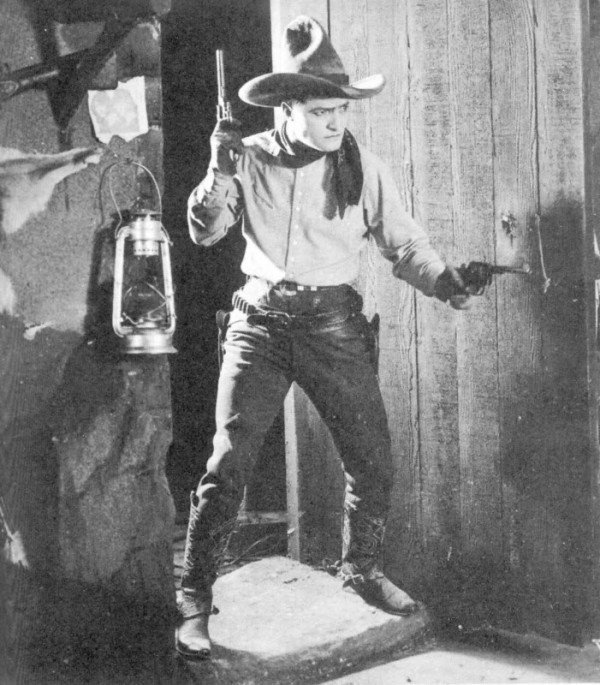

Western star Tom Mix wearing jeans in “The Untamed” (1920)

It wasn’t until the 1920s that denim’s reach began to expand beyond workwear. Denim jeans became the de facto cowboy uniform in revisionist Hollywood western films and children all over the country wanted a pair so they could dress up like their on screen idols. At this point, denim was still largely a costume to most Americans, but it did serve to normalize denim to the middle class.

During WWII, many Americans put on denim for the first time as they went to work in factories to produce for the US war effort. Once the war ended, however, many soldiers and workers refused to take their jeans off. This gave denim a countercultural and anti-social bent, wearing jeans in polite company in the 1950s was considered transgressive at best and immoral at worst. This sentiment resonated well with suburban teenagers, who identified with the anti-authoritarian and denim clad characters in movies like Rebel Without a Cause and The Wild One.

James Dean wearing Lee Riders in the 1955 film “Rebel Without a Cause”

The breaking point, however, finally came with the Elvis Presley film Jailhouse Rock. The ensuing popularity of the King’s hi-gyrating antics was too much for mainstream Americans to deny, and over the next couple of decades, denim gradually became accepted as a casual clothing option.

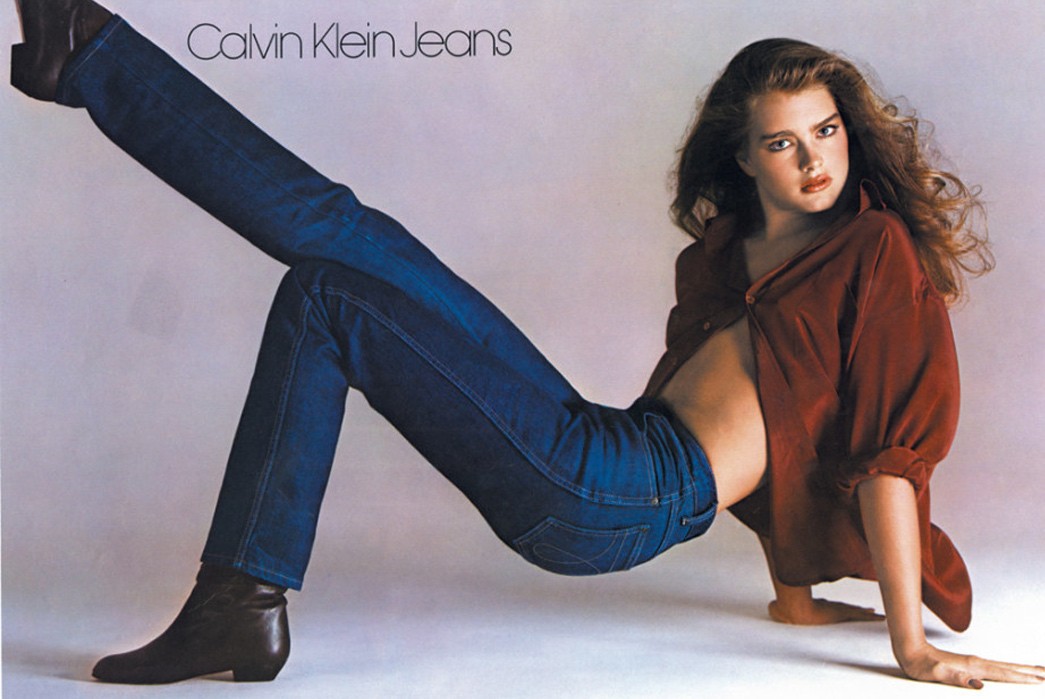

Average Americans, however, weren’t used to the break in process nor the fades that could take months or years to get perfect. The most popular casual denim brands in the 1970s and 80s were those that stonewashed and distressed their jeans before the customers bought them and saved them the effort of breaking them in. So now everyone could put on a pair of jeans that felt like pajama pants right after they pulled off the price tag.

Brooke Shields wearing broken in denim for her famous 1981 Calvin Klein ad.

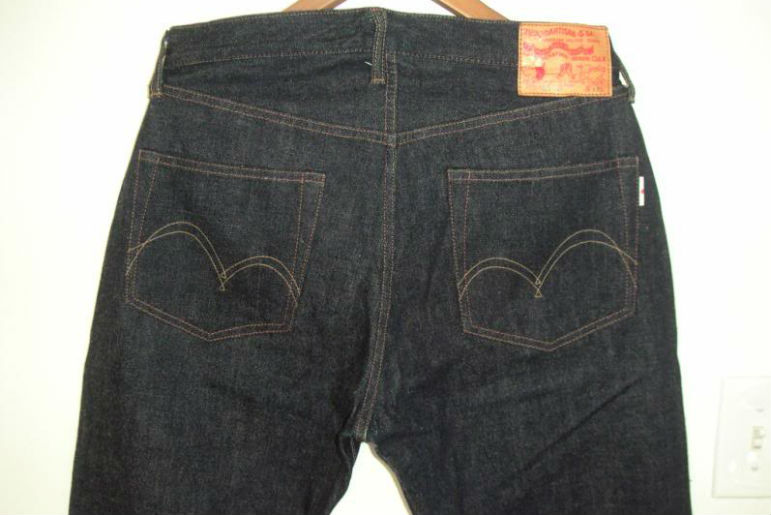

During this period, Japanese denim enthusiasts became disillusioned with American denim manufacturers. They believed that Levi’s, Lee, and the other brands had lost their way, and a small group of Japanese companies began reproducing jeans in the same manner as the American brands from the 1940s, 50s, and 60s. They rewove their own selvedge denim, recast buttons and rivets, and even bought up the old sewing machines that used to make American workwear so they could produce their own new “vintage” jeans.

A pair of Japanese made jeans from Studio D’Artisan.

These “reverse-engineered” jeans from brands like Studio D’Artisan, Evisu, and Denime began to expand beyond Japan in the late 1990s and soon inspired a new wave of American brands to recreate the jeans of the past with their own special touches and fabrics.

With these new brands like Raleigh, Left Field, and Tellason producing and selling domestically in the late 2000s, raw denim’s popularity in the United States grew rapidly. Today, there are dozens and dozens of small manufacturers making raw denim all over the world, enough to the point where sites like ours exist to document it all.

How Raw Denim is Made

So how does that iconic and international fabric get to the point where it can be made into pants? We’ll leave out some of the details here, but in a nutshell, raw denim jeans are produced via these steps:

Sourcing

Assuming the denim is produced with 100% cotton, the first step is simply sourcing the cotton plants. Cotton can be sourced from many different countries, ranging from Australia to Zimbabwe; and there are a variety of breeds and strains that have different properties like luster, softness, and durability.

How the cotton is harvested varies with location. There are those that pick the cotton by hand while some employ mechanical techniques. Steps taken afterward include cotton carding (i.e. cleaning), inspecting, combing, opening, and blending – essentially making the cotton clean and removing all impurities and chaff so it’s ready for the next stage.

Spinning

Now that the cotton has been sourced, cleaned, and packaged in nice long “slivers”, it’s time for it to be spun. The individual cotton fibers are combined and twisted to create the yarns that will eventually be woven to create the denim fabric.

There are several types of spinning, including open-end, ring, and double ring spun (aka “ring-ring”). Though there are many more details included here, note that ring and double-ring spun denim is more desirable – since it is thicker, leads to stronger fade contrasts (it doesn’t absorb indigo dye as well as open-end spun denim), and has greater slubbiness (uneven threads).

Warping & Dyeing

The cotton moves on to the next stage, “warping”. Woven fabric consists of warp yarns (length-wise, indigo dyed) and weft yarns (cross-wise, left un-dyed and thus labelled “filling yarn”).

Warp yarns are prepared by selecting the longer yarn from the ring-spun yarn and dyeing. There are three main methods of indigo dyeing – loop dyeing, slasher dyeing, and rope dyeing. We’ll explore those more in depth in the future, but know that rope dyeing is considered superior as it is more laborious, specialized, and results in better fades (due to only the yarn surfaces being dyed).

In general, the indigo-dyed warp yarns are interlaced with the natural colored, un-dyed weft yarns, and there are two types of looms – shuttle looms (remember when we mentioned those above?) and shuttle-less (aka air-jet or projectile) looms. While the former produces less than the latter, they are more rare, result in finished edges (hence, “self-edge”), and typically more coveted (though this is of course subjective).

There are also a variety of weaving variations, including right-hand twill, broken twill, and left-hand twill; and the end-result is a sheet of denim fabric.

Finishing

The denim sheets are then rolled into drums and shipped off to the brand that’s going to make it into jeans. Some denim brands complete their sewing and stitching via larger facilities, while others favor one-man operations (such as Ande Whall and Roy).

That’s it! Not once during the finishing process is the denim distressed or washed in any way. It is left in its most pure and rawest state, and will only deteriorate with the wearer’s personal use.

Raw Denim Terms to Know

When you first hear a denimhead talking about raw denim it can sound like a foreign language (slubbiness, nep, 3×1 twill, etc.). You can get to those later, but there are a few terms that will help you understand enough to make your first informed purchase.

Selvedge

The selvedge outseam on a pair of Japan Blue Jeans.

The most common word that you’ve heard surrounding raw denim is probably Selvedge–this refers to those little colored lines that often run along the outseam of a pair of jeans. Simply put, selvedge denim has had the edge of the fabric “self-edged” by a shuttle loom as it was woven to keep it from unraveling. Just because it’s selvedge though doesn’t mean it’s raw or even that it’s denim — almost any fabric can be woven with a selvedge.

Selvedge textiles for the most part faded away in the 1950’s when denim demand skyrocketed and manufacturers like Levi’s and Lee switched to the far-cheaper and faster projectile looms, but there has been a strong resurgence amongst raw denim fans in the past few years. A selvedge line doesn’t necessarily equate to better denim, but the mills producing the most interesting and highest quality fabrics are usually producing them on selvedge shuttle looms.

Sanforization

Unsanforized shrink to fit denim before washing (left) and after (right).

Another term you might have encountered is Sanforization. Almost every fabric, including denim) will shrink a certain amount the first time it gets wet. Most denim on the market (raw and otherwise) is sanforized, which is a steaming and heating process that pre-shrinks the fabric before it is cut and sewn into jeans.

Unsanforized denim (often called “Shrink-to-Fit”) will shrink about 5-10% the first time it is washed. You have to be much more careful when sizing unsanforized denim and factor that it may shrink up to two inches in the waist.

Weight

Five pairs of heavyweight 20oz. Elephant denim stacked next to five pairs of midweight 12oz. denim jeans.

Another focus of raw denim is the Weight of the fabric. The weight refers to how much a yard of the fabric weighs in ounces (oz.). Weights can range from the ultra-light at 5oz. all the way up to the monstrously heavy 32oz. A heavier fabric will be stiffer, tougher, and require more effort before they are comfortable. Most raw denim, however, will be somewhere around 12oz.-15oz. This weight can be worn year round and won’t be too much of a pain to break in.

Learn all about other denim terminology via our Dictionary.

Your First Raw Denim Purchase

Now that you know the appeal of raw denim and some of the basic language around it, how do you go about buying your first pair?

Measurements

Unless you live near a brick and mortar store (find out if you do with our Store Guide) you’re most likely going to be buying your jeans online. To make sure you buy jeans with the proper fit, you first need to know your measurements. There are six key measurements you’ll want to take into account:

- Waist – Circumference of the jeans top block

- Rise – Length from the top of the inseam to the very top of the fly

- Thigh – Distance from the top of the inseam across to the outseam

- Knee – Distance from the inseam to the outseam halfway down the jean

- Leg Opening – Distance from the inseam to the outseam at the hem of the jean

- Inseam – Length from the bottom of the crotch to the end of the leg

You can find your ideal measurements by taking a measure tape to your best fitting pair of jeans. Pretty much every raw denim retailer has these numbers listed on their website, so once you know your measurements, you’ll have the confidence to buy any jean, anywhere.

Fits

Slim Straight (Left Field Greaser) and Slim Tapered (3sixteen ST-100x)

Like most everything you wear, fit is especially critical. Straight Leg, Tapered, Slim Tapered, and Slim Straight are all common fit options; you’ll have to consider what works for you in terms of comfort and look. It’s not worth sacrificing your future children to stuff your tree-trunk thighs into a pair of heavyweight skinny raw denim that feels like Kevlar. Buy what works for you, and you (and your future generations) will be infinitely happier.

Budget

Momotaro Gold Label jeans are made from hand woven denim and retail for $2000.

Next, consider your budget. Raw and selvedge denim can range anywhere from $20 to $2000. The reason for this is the massive number of different fabrics, details, and manufacturing techniques available on the market.

Keep in mind that just because a jean is more expensive does not necessarily mean it will be more durable, many of the manufacturers at the higher price points are simply offering something you can’t find anywhere else. For example, Roy Slaper of Roy Denim makes every single pair of jeans himself on rare vintage sewing machines, Sugar Cane & Co. in Japan uses a specialty denim that weaves in sugarcane fibers with the cotton for a unique feel and fade, Naked & Famous even makes a scratch and sniff denim that smells like raspberries.

If you want to learn more about what separates the different price points of jeans, have a look at our article The Three Tiers of Raw Denim: Entry, Mid, and End Level.

If you’re just getting into raw denim, however, the best entry level jean we recommend is the Tellason Stock jean, it costs $99 and you can read all about why we picked it here.

Caring for Raw Denim

Now that you’ve got your raws, how do you care for them? Fades are such a central part of raw denim’s lore that they are celebrated unto themselves with fanatical devotion. The longer you go without the first wash, the greater the fades can theoretically be. However, the oft-repeated adage of wearing your raw denim for at least six months without washing can be a little overkill.

Some people put their jeans in the freezer to “kill” the funky odor-causing bacteria, but it’s not conclusive if that truly works. What we say is just wash your jeans when you feel like it. While no washes might make for more extreme fades, it also builds up dirt and grime in the fabric which only leads to more holes and blowouts. A safe balance is to wash your pair every month or two with an all-natural soap like Dr. Bronner’s or a detergent for dark colors like Woolite, but that’s by no means a hard-and-fast rule.

The biggest takeaway from raw denim is that these pants grow to reflect who you are and what you do in them. So live your life, treat them like hell, and wash them when you think they need it. When you’re ready to wash, have a look at our complete washing guide to how to do it right.

The reason people are so crazy about raw jeans is because you essentially make a pair your own. As many denimheads say, “it’s a canvas that paints itself.” We hope that we’ve cleared up some of the mystery and myths surrounding raw denim so you can get to work on painting that first masterpiece.

Now that you’ve read all about raw denim, have a look at some of our other primers on boots, leather, and more.