We’re giving away a full Tellason kit of a watch cap, tee, and jeans including a fit consult with Tony and Pete. Keep reading to enter below.

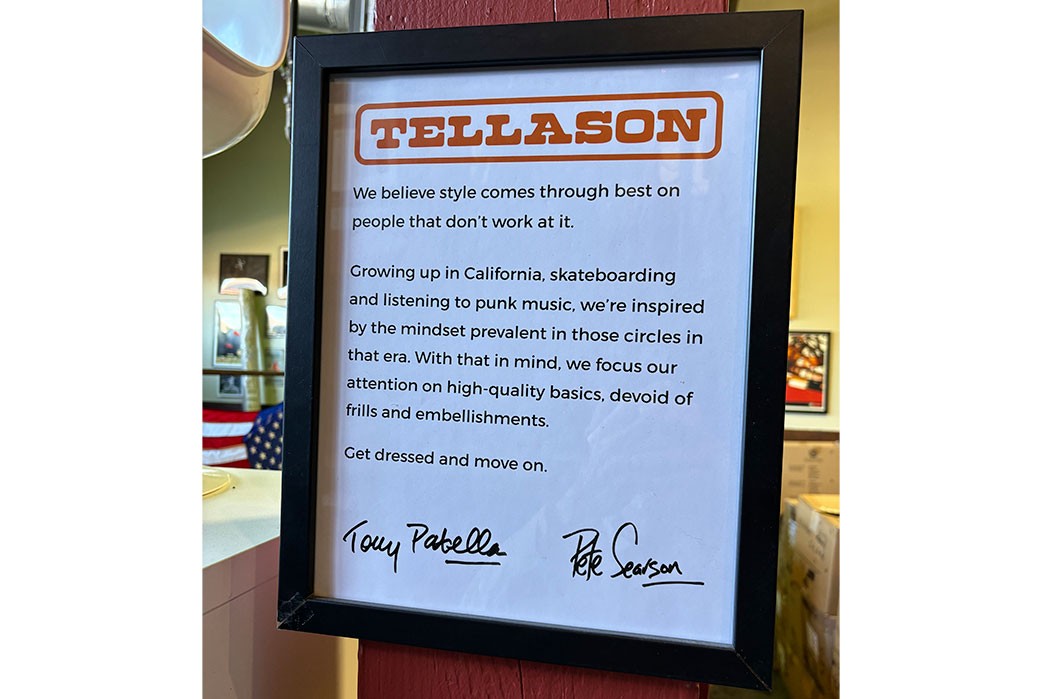

California: home of the redwoods, Big Sur, Mount Whitney, and this support beam in an industrial building in Sausalito. On it is Tellason’s brand philosophy, which I’ll let you read for yourself.

“Get dressed and move on,” isn’t the message you’d see from a typical fashion brand, but Tellason’s founders aren’t your typical fashionistas. When asked on brands they admire, Pete and Tony list Stüssy surfboards from the late 1970s, Richard Sachs’s bicycles, and an Eero Saarinen coffee table—all items with a modern design, high-quality build, and made to be used for decades. Once you have one in your life, that need is solved for a good long while.

If you’re even a marginal fan of raw denim, Tellason has likely been on your radar since you googled how to do your first bathtub soak. They’re well established as one of the canonical brands in our niche, gradually expanding from offering one pair of jeans to a collection of over a hundred different pants, shirts, outerwear, and more.

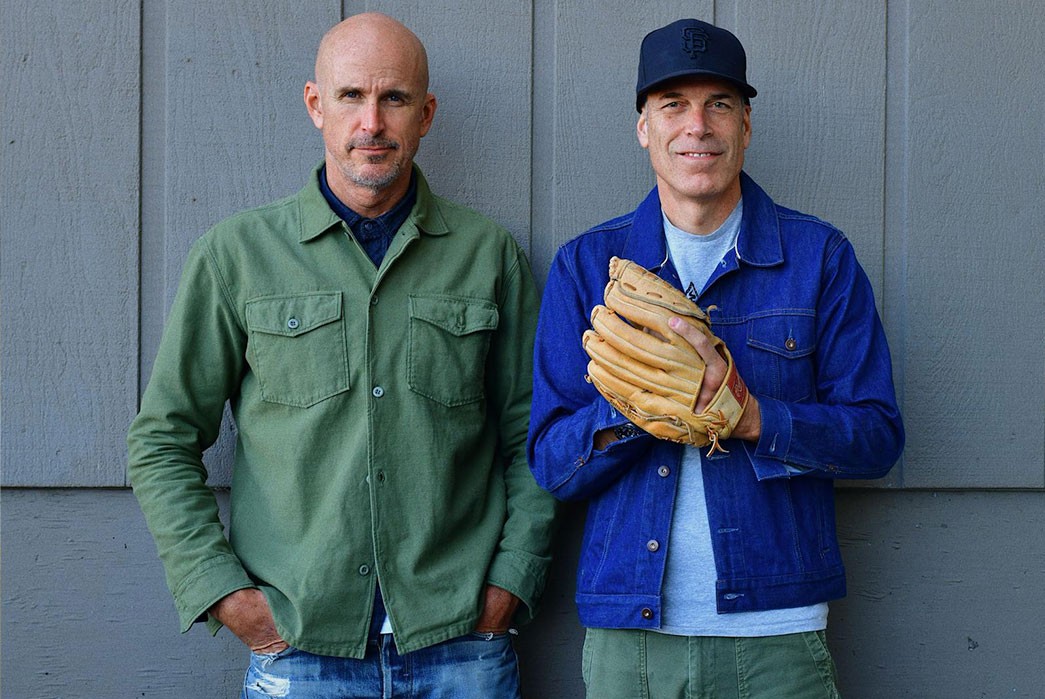

But you probably don’t know the two guys who are Tellason. The name is literally a portmanteau of their names, Tony Patella and Pete Searson, two friends and business partners who have been helping people get dressed and move on for most of their lives.

The People Behind the Name

Tony (left), Pete (right), and Francesca (bottom).

Both Pete and Tony are products of California. Tony from the north, Pete from the south. They were born two weeks apart from each other and both attended San Diego State University. They likely passed each other in the crowd at many of the same punk rock shows, but didn’t meet until after graduation in 1990.

Tony was working in his dad’s sporting goods store and Pete was a vendor selling action sports gear and apparel. After discovering all of the above connections, they became fast friends. They worked in some of the same companies together, were in each other’s weddings, but each had their own area of focus.

Tony moved from sporting goods store to denim after he met another Bay Area denim legend, Cliff Abbey (previously of Sticky Fingers and Claudio Agnelli), and helped him launch a vintage-inspired denim line called Sutter’s (like the Gold Rush mill). It was here that Tony learned how to source fabric, develop samples, and quality control production. This was in the pre-NAFTA 90s so even as a mainstream brand, Sutter’s was made with Cone Mills White Oak denim and their first year of cut and sew was all in San Francisco, connections he wouldn’t soon forget.

At the same time, Pete was racking up international sales in the world of action sports, developing a skillset and a network of vendors all over the world.

Going From 0 to 1 (Pair of Jeans)

The very first sample pair of Tellason jeans.

By 2008, with the global economy in the toilet from the Great Recession and retail weaker than ever, Pete and Tony thought it was the perfect time to start a new brand.

They will be the first to tell you that the world doesn’t need another denim label, “If we stop making jeans, people aren’t going to start walking around naked.” Tony quips, “But there is always room for people willing to do something better or differently and provide really good service.” And there was need for a quality, well-fitting, understated jean that could be the bridge between a Filson jacket and a pair of Red Wings or Aldens.

Pete and Tony at the 110th anniversary celebration at Cone Mills White Oak Plant in 2015.

All the pieces were there: they bought some denim on the credit of Tony’s good name at White Oak, went back to the same sample line they used at Sutter’s, and made a pair of jeans.

Then another.

And another.

Pete would try them on right there on the sample floor and Tony would make small notes and adjustments back to the sample sewer and after four pairs, they had the one. This pair of slim-straight jeans was their one and only offering at Tellason.

They made a run of 240 of them and hit the bricks for retailers in the Northern California and Pacific Northwest area, making store owners try the jeans on for themselves. They sold all 240 in their first round of sales calls and went back for another 240 once word got out who had picked them up.

And another.

And another.

Growth by Association

Pete and Tony visiting Osaka retailer First.

The growth of the brand was in part the growth of their connections. They’ll tell you, “we aren’t smart enough to come up with all this ourselves so we have to turn to others for help.” But I would say that’s the genius behind Tellason’s success. It’s all been organic growth and following good ideas wherever they turn up.

Initially, they only had the one slim-straight jean, the John Graham Mellor, until Michael Williams, of A Continuous Lean, asked if they could make a straight leg that fit him a bit better. After a long exchange of Fedex packages and phone photos, the Ankara fit was born.

Then they did a small collab with a Dutch denim shop and noticed that the owners were wearing their jeans with a heavy taper below the knee. After learning that nearly every customer altered them the same way, Pete and Tony took it back to the factory, where it became the Ladbroke Grove, their current best seller.

A limited edition pair done in collaboration with the White Oak Legacy Foundation and Proximity Mfg. Co.

Customers at Burg und Schild, Berlin’s premier motorcycle outfitter, wanted something heavier to wear on their bikes. Tellason’s beefier 16.5oz. denim showed up shortly after. Steve at BlackBlue in Minnesota told them he wished the Ladbroke had a slightly higher rise–enter the Elgin, the jean Tony was wearing as he spoke to me.

In every instance, Tony and Pete had taken the time to hear their community’s needs and create a thoughtful response. And almost every time they’ve been rewarded for it.

Staying True to Tellason

Fresh cuts on the table at their San Francisco factory.

Despite being open to suggestion, Pete and Tony know what their lane is and how to stay true to it. “You can’t’ be everything for everyone.” Pete laughs at the memory of a Tommy Hilfiger snowboarding display at Macy’s years ago, “Could you imagine Tommy himself on the mountain in that gear?!”

Tellason has seven denim fits that fit most but not all, tees that fit some but not everyone. And aside from the purist ideals of no stretch denim and no washes, there are some other key values they won’t budge on.

Distribution is something they’ll always do themselves (when the language barrier permits). You won’t find Tellason with an agency or in a showroom in the U.S., and aside from a few international distributors, they sell it themselves and want to represent it themselves. And they’re very particular that they are only sold by retailers who get what they’re doing. They have no desire to be on a department store discount rack sandwiched between shredded pairs of commodity denim.

Tellason is fully committed to their hometown San Francisco factory Tony started working with almost 30 years ago. They could make it much cheaper overseas or even just down the coast in LA, but no other factory is making jeans in San Francisco and, as Tony laments, “If that factory closed, land in the city is so expensive that no one else would ever start another. We’re not going to be a reason why they close.”

And speaking of the factory, they will never do full-package production. Most brands go soup-to-nuts at one manufacturer and make their garments with what they have on the rack. Not Pete and Tony. They source and spec every piece of their product, from the denim to the rivets to the thread to the leather patch. The relationships they’ve kept with their suppliers is as crucial as those with their customers.

The Tellason Experience

The Tellason “Wall of Fades”

If you’re interested in a Tellason pair of jeans, jacket, or tee, there’s no one better to visit than the guys themselves. Pete and Tony aren’t Tommy Hilfiger trying to sell you a snowboard, they’re literally the fit models of their own product.

Like most brands, every piece they make is available on their website. But unlike most brands, they offer an unparalleled quality of service. Pete and Tony know their collection inside and out and use every ounce of expertise to get customers into the perfect pair, often talking them through different fits and features over the phone.

Their new customer process for denim is as follows:

- Make sure they get the right fit for the customer’s body type (as mentioned, Tellason has seven).

- See what kind of shoes they like – tapered for sneakers, bigger for boots.

- Find out what jeans they’re currently wearing and if they like how it fits.

- Ask what denim weight they’d like (Tellason offers jeans in 12.5oz., 14.75oz, and 16.5oz. indigo and 13.5oz. black/black in their proprietary Japanese Kaihara Mills selvedge denim).

The 12.5oz. Ankara, available for $240 at Tellason.

From there, they want them to thrash it. “I hate hearing people refer to us as their ‘date night’ jean,” Tony says. Pete points to their “Wall of Fades” of Fade Friday-worthy jeans from past Tellason-wearers like John Doe of the band X to a friend who works construction, “We want them to look like that.”

A Fade Friday of that same Ankara fit after five years of wear.

Even though they identify as a luxury brand, they don’t want their clothes treated like precious luxuries. Tellason products are something people can get a lot of use and utility out of, it’s not expensive if you use it a lot, repair it, and come back for more a few years later.

Once Pete and Tony have gotten you into a pair of Tellasons, all you need to do is get dressed and move on.

Tony and Pete on Saarinen chairs outside of their Sausalito HQ.

For more information and to see all their offerings, visit Tellason’s website.