In the four years I’ve been writing here, I’ve been amazed by, in that relatively short span of time, the number of “new” brands that have gone on to become the “old” guard. A love of indigo (and love can often lead to bad decisions) has led many companies to a death by red ink, so those who have managed to stick around deserve another look.

In my opinion, longevity goes beyond styles and price points, a prolonged success speaking well for the heart and soul of those behind the drawing board and ledger. I can think of no brand that’s governed by stronger ideals than Richmond, VA’s own Shockoe Atelier. The explanation of our headline is found in this statement from their Web site:

Made By Immigrants In The U.S.A.

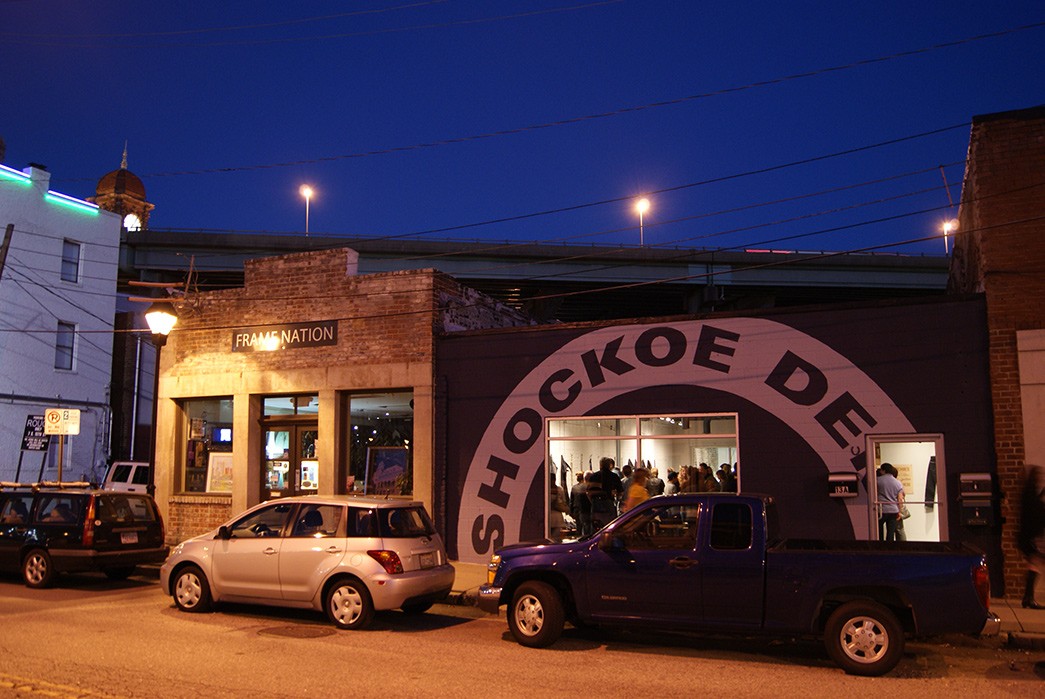

When we say that our products are “Made By Immigrants In The U.S.A.” it is also our way of saying made by Americans, as it is our belief that we are all immigrants here of one kind or another. Shockoe Atelier is a funny collection of French, Korean, Mexican, Guatemalan, Scottish, German, English and so on – brought together by fate or circumstance – with the gumption to endeavor to make a line of classic American apparel in an old cinderblock box of a building at the doorstep of the American South.

What’s not to love about that? Especially today when too many in America have forgotten that the success of immigrants and the success of business are inextricably linked. When we first wrote about Shockoe back in 2014, we dug deep into their deep roots in “legit” fashion. In my recent conversation with founder Anthony Lupesco, I pick up where that conversation left off, exploring the benefits of working with an extended family and keeping the process close to home in a hotbed of the New South.

Shockoe Founder, Anthony Lupesco – Shelby Lum / Richmond Times-Dispatch.

Anthony Lupesco: When we first started we didn’t know how to make jeans. The story I hear most often is folks start making jeans by looking up how, “they used to be made,” by Levi’s. We didn’t know enough to do that, so we relied on my family’s experience with fine tailored goods to figure out how to make the best pair of jeans we could. I think this makes our jean look and feel pretty different, and harder to categorize.

Heddels (John Bobey): You’re based in Richmond, VA – do you think there’s anything particularly “Southern” about Shockoe…does it inform your design or brand in any tangible way?

AL: I’m not sure that we can claim we’re “Southern,” but we are definitely a Richmond Brand. Having a store directly in front of our factory has led us to having a design process that very much involves our city.

H: Does it help being outside a traditional fashion center like LA or NY?

AL: We might move a little slower outside of NY and LA, but I think that’s a really good thing. It allows you to really develop your identity and stay true to it rather than get all wrapped up in trend driven whirlwinds. I’m also not sure we would get the same kind community support in NY or LA…there’s a lot of creative energy and goodwill in Richmond right now.

Shelby Lum / Richmond Times-Dispatch

Shelby Lum / Richmond Times-Dispatch

H: We (Heddels) first talked to you in 2014, just a few years ago but an eternity in the premium denim business. With so many brands finding it difficult, or altogether impossible, to compete, how is it that you’ve managed to keep Shockoe not just in the black, but increasingly relevant?

AL: Having our own manufacturing facility gives us a ton of flexibility and the ability to experiment with new styles and methods quickly. This can also be a big challenge at times: we’re a super small shop–nine people total–we’re like family. When things are slow, factories usually will send people home for extended periods of time. We can’t do that–you can’t send family home. Because of all this we’ve grown really slowly organically. Having our own retail store and community support has really been key for us.

H: In preparation for this piece, I’ve been happily wearing your Wheeler Relaxed jean. For starters, why call it the Wheeler?

AL: I wish I had a great origin story, but it’s named after a customer of ours whose jeans fade beautifully and always with an earthy tint. The unbleached weft reminded us of his jeans.

H: This is Japanese denim, which you use a lot. What goes into the decision on where to source your denim, and how do you conceive the recipes for the weave?

AL: We always try to imagine what the fabric will look like after some wear. To me the key to a great fade is the texture created by the beautiful imperfections iconic to selvedge denim. The Japanese are the best at this. We also source denim from Candiani, which is really easy to break in, for the guy who is just getting into it. It’s kind of a gateway jean.

H: Now that the Cone Mills White Oak plant has closed, it appears that all denim will be sourced overseas. Can you imagine Shockoe ever using Chinese long-staple denim? Where else might you find yardage you’d like to use?

AL: We’re open to sourcing denim from anywhere as long as we like the quality and the fabric is interesting. One of the major issues we face as a small manufacturer is we can’t meet the high minimums required by the larger mills in India, China, Pakistan etc.

H: How important is it that you sew all your own pieces here in America…what does “Made In USA” mean to you?

AL: I think we should be close to the products we make, that’s why I’m so proud of being “Made in Richmond.” That being said, we have made jackets in Italy because we really connected with the manufacturer and his approach to making things. I would certainly prefer to make everything domestically, but I think it’s more important to make the best product you can, wherever that takes you.

H: Other than pure creativity, what criteria do you use when deciding to add a new piece to your collection?

AL: Just like food, if you have good ingredients, don’t fuck them up…let them shine. Almost all of our details are hidden in the construction, some you won’t notice until after a few months of wear. At the end of the day I want everything we make to be worn and loved and I think the key to that is using fabrics that change with you over time, and simple designs that last can stand up to fading trends.

H:I’ve also been wearing your Cottrell Field Shirt–it’s a nice example of your point. I find that it rides the line between a shirt and jacket, but really not feeling at all like the shirtjacs that most brands seem to offer. Maybe it’s the slash pockets?

AL: I think so, most welts are made using an automated machines, we make them by hand. I think it looks cleaner and also those machines are expensive!

H: Your denim blouson intrigues me. I for one love the idea of a denim jacket that breaks from the classic trucker design, but the alternatives all seem to err too much on the side of singing cowboy, as much costume as clothing. For me, Shockoe’s is in the sweet spot…something you can wear without fearing a request to yodel. What was the inspiration?

AL: I really wanted to make our own version of a denim classic. I wanted to reference my family’s background through shape and stitching but also be minimal and easy enough to just throw on walking out of the house. More uniform than costume.

H: Growth seems to be a double-edged sword in the premium denim world. You of course want to reach more people and grow as a company, but that can often mean making compromises in terms of the where, how and “of what” pieces are made. What’s your strategy for Shockoe’s future?

AL: Slow and steady.Keeping the selection tight and only putting out what we truly believe in.

H: Have you ever considered staying “small” as a trade-off for maintaining quality and control?

AL: I think about that all the time…it’s such a tricky balance. Today, I’m able to physically inspect every item we ship out. I’m proud of that.

Shockoe Product Overview

That pride certainly came through in the Shockoe pieces I’d worn in the past–a while back I reviewed Shockoe’s Old Boy Kojimas and loved them, and when they came out with their recycled Elmores (sadly no longer available), I snagged a pair of those as well (can’t wait to see how the grey/white fades in a few months). The four new pieces I’ve been wearing for the last eight weeks or so were true to form, and did not disappoint.

Denim Blouson

Shockoe Denim Blouson

When Shockoe’s Denim Blouson ($295) was first released, Managing Editor David Shuck sang the praises of its rounded pockets. As I told Anthony, this stylized take on a denim jacket is just snazzy enough to make sure everyone knows it’s not another Trucker Jacket, and yet doesn’t tip the scales into being a a wardrobe option for a revival of Oklahoma!

I know some of you might scoff at the fact that it’s rinsed denim, but I say that’s what I like about it. Since I’m in denim bottoms most of the time, I avoid a denim jacket so as not to achieve the “tuxedo” effect. So that means I only wear a denim jacket when I’m wearing some other pant, and that’s not often enough to adequately (or in my lifetime) break in a raw denim version. This solves that problem, and the contrasting cuffs and color are sweet. I take a 36″ sleeve, and this XL fits perfectly.

- Rinsed 12.5oz dark indigo, tinted-weft selvedge denim from Candiani Mills, unlined

- Shockoe tobacco leaf-stamped copper hardware with black finish

- Leather-backed hardware

- Adjustable side cinches at waist

- Contrast corduroy collar and inside cuffs

- Lined pockets

Cottrell Field Shirt

The Cottrell Field Shirt ($225, more like a shirtjac), unlike the Denim Blouson, will take a few wearings (I wash jackets as infrequently as jeans…just me?) to break in and get comfy, but I’m up to the task. In the XXL I’m wearing (sizing up was common with this piece), I wouldn’t get too much more underneath it than a t-shirt, so it certainly falls more to the shirt side of the spectrum. I love the color…deep green but not OD…kind of a “jumbo trash bag” green? (forgive me Anthony), and as I wrote earlier, slash pockets on this kind of garment are a real plus. After all, who puts their keys in a chest pocket?.

- Raw 9 oz. double-faced twill from Spain

- Charcoal warp – Olive weft / 98% Cotton, 2% Lycra

- Chest pockets with flapped snap closure

- Slash hand pockets, front snap closure

- Shockoe tobacco leaf-stamped hardware in copper with black finish Leather-backed buttons and rivets

Relaxed Wheeler

Relaxed Wheeler

Anthony sent along two new “bottoms” for me to try out, and the first is the Relaxed Wheeler ($250), a beautiful pair from Collect Mills in Okayama, Japan, made from mid-weight slubby Zimbabwe cotton. I’ve found that too often a “relaxed” cut can actually be baggy, but this pair is true to its name, giving a bit more breathing room in the seat and thigh while still offering a tapered leg.

Nailing a cut like this is surely evidence that Anthony’s family background in high fashion is coming in very handy. I’m in a 35 (18.75″ waist, 10.75″ front rise, 16.5″ back rise, 13.75″ upper thigh, 9.75″ knee, 8.25″ leg opening, 35″ inseam), and I’m finding the adjustments to the relaxed fit spot on, making them equally comfortable and flattering as my other Shockoe slim cuts.

- Raw 13 oz. selvedge denim from Collect Mills / Indigo warp – Natural weft / 100% Cotton

- Classic contrast stitching

- Branded black coated copper rivets and buttons that will fade/wear to show copper over time

- Leather backed Rivets and Buttons

- Lined back pockets.

- Reinforced front pockets.

- Chain stitched hem

- Hidden selvedge coin pocket

- Veg-tanned leather patch

- Free repairs for the life of the jean

Slim Indigo Canvas

Last up is a pair of pants that offers the versatility (at least to me) of being able to wear non-denim but still reap all the benefits of a fabric that should fade like my favorite jeans. Shockoe’s Slim Indigo Canvas ($225) is made from raw 11 oz. saturated indigo selvedge canvas from Berto in Italy, with an heavy indigo warp and weft.

Will these fade like denim? Only time will tell, but I’m optimistic. Mine aren’t showing too much wear as of yet, but my guess is they won’t until that initial soak when I turn my tub blue. (Again. Sorry Mrs. Bobey.) These are a low to mid rise, and slim all the way down. (My 35’s = 18.5″ waist, 10.5″ front rise, 15.5″ back rise, 13.5″ upper thigh, 8.75″ knee, 7.5″ leg opening, 35″ inseam). I won’t be wearing ’em on an In-N-Out binge, but for a night on the town with some shell cordovan brogues, I believe I’ll be the sartorial team to beat.

- 100% cotton

- Tonal stitching

- Branded black coated copper rivets and buttons that will fade/wear to show copper over time

- Leather backed Rivets and Buttons

- Lined back pockets

- Reinforced front pockets

- Chain stitched hem

- Hidden selvedge coin pocket

- Veg-tanned leather patch

- Free repairs for the life of the jean

In a perfect world, every company who tries to find success in the premium denim world would do so–after all, I’m a fan, and I’m rooting for these men and women to succeed (and allow me to fill my closet).

But I’m also a champion of a meritocracy, where a guy who throws the fastest baseball or the company that chooses to be guided by taste and a moral compass as much as profit finds the most success. Anthony Lupesco’s Shockoe Atelier is clearly doing it right, and a big part of that is doing the right things–embracing his workforce, pacing their growth, sweating the details, and contributing to his community. By wearing his stuff, I get to feel a part of that community. Nothing wrong with looking good and feeling good, right?