With the world barreling ever deeper into climate change, the impact of the fashion industry cannot be understated. Even so, the topic of sustainability is complex and confusing. We asked Soorty, a leader in denim production and sustainable practices for their thoughts on sustainability. Their level of production makes the company a huge influence and their recent innovations can provide major positive results. Soorty’s Executive Director of Global Sales & Marketing, Ebru Debbag gives her thoughts on sustainability means and how Soorty’s Fix-D process and innovations in recycled fiber technology are helping to make big strides in sustainable fashion.

We at Soorty are aiming to build an evolving structure of value definition that can transcend responsible design and manufacturing of denim and jeans. Our annual scale of producing 80 million meters and 55 million units presents us with the responsibility to make a positive impact. Our actions make a difference.

Soorty has invested in manufacturing recycled cotton and we use responsible raw materials such as tencel, refibra, repreve, linen, and hemp as we design denim. We work with updated technology to save water in the production of denim fabrics as well as garments. Soorty’s Gold Certified C2C Line was launched in 2018 in collaboration with the digital fashion house The Fabricant using the first digital denim garment. The fact that our fabric and garment product development teams can work together gives us access to key and lock projects.

The industry is looking for opportunities for collaboration based on transparency as well as storytelling. These are the most important features that can transcend innovative applications for consumers. The denim industry works with a complicated and global supply chain and key and lock projects are where we can create a value chain where working collaboratively brings extra value. The communication of key and lock projects not only creates value and speed to market solutions, but it simply makes sense for the consumers as well.

Fix-D, Zero-Water Garment Dyeing

Our recent Fix-D process will be a game-changer in the fabric dyeing process where we can achieve garment dye without using water and we will launch Fix-D during our AW2021 presentations. The process is developed in our R&D center based in Çorlu where we host workshops for designers, brands, and customers as well as denimheads and students from around the globe. The Fix-D garment dye process itself is water-free and water is used only as at the pre-wetting stage. In total, Fix-D uses 85% less water in the overall garment dyeing process compared to current methods. Soorty is a global company with local solutions and we understand the need to deliver better products faster and still define the beauty of the fabrics and jeans that we produce.

Fix-D is a responsible innovation that saves water on both the process of garment dye as well as thereafter at the garment wash stage – water is what the industry is looking to save and reuse. The denim industry is constantly looking for possibilities that can improve the way we work and to propose an updated product to the consumers. The Fix-D process is also laser friendly and that makes the process further beneficial for the garment wash process. It is also a unique circular innovation model that can be used at scale. We believe that innovation needs to cater to multiple needs and Fix-D is a great example and the story of the process is easy for consumers to understand.

Recycled Fabrics, Hurdles, and the Future

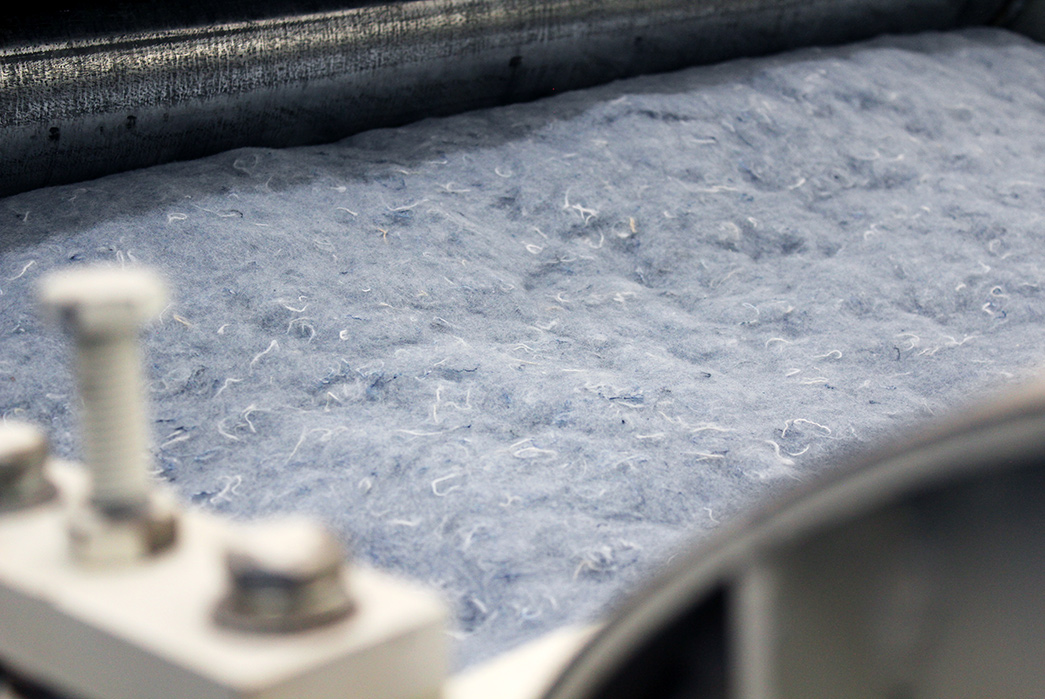

Recycled post-consumer waste (PCW) requires a built-in circular model where the used garments need to be collected and sent to the recycling plants. This is the step where we have to be careful to not create a product that defeats the purpose. At Soorty we have a major advantage in that we have our recycling plant integrated into our spinning and we can produce our own recycled PCW as well as post-industry waste (PIW) yarns. Recycled cotton content fabrics need to be designed with utmost care so as to not to compromise the strength of the fabric and we feel comfortable with our 5-20% PCW recycled fabric and have recently developed our REJOY and RELOVE fabrics that have even higher recycled content.

The collection of used garments locally as well as the availability of recycled yarn production facilities are the main hurdles. We work with I-CO and utilize production at our own recycle spinning and we are adding new products to our recycled collection. The industry has been flooded with polyester content denim fabrics for the past 2 decades and it is also a challenge to separate the poly and the lycra from the cotton content and this again is a crucial step to solve in increasing the availability of recycled products. I know that innovation is underway and a lot of research is being done and we will need scaling to change the dynamics.

We have implemented recycling as a business approach and aim to inspire the industry and have recently been also looking at how to work with young designers to work on “waste” materials so that we can further promote the idea of recycling and putting to re-use in our industry. We have launched a mini collection with 2 Dutch Designers and will be further promoting the idea of waste becoming a resource in our collections.

To learn more about Soorty and their innovations, visit their website.

All images courtesy of Soorty.